What's New in V0.2

There are many design changes from Genesis V0.1 to V0.2 that make this version a huge improvement:

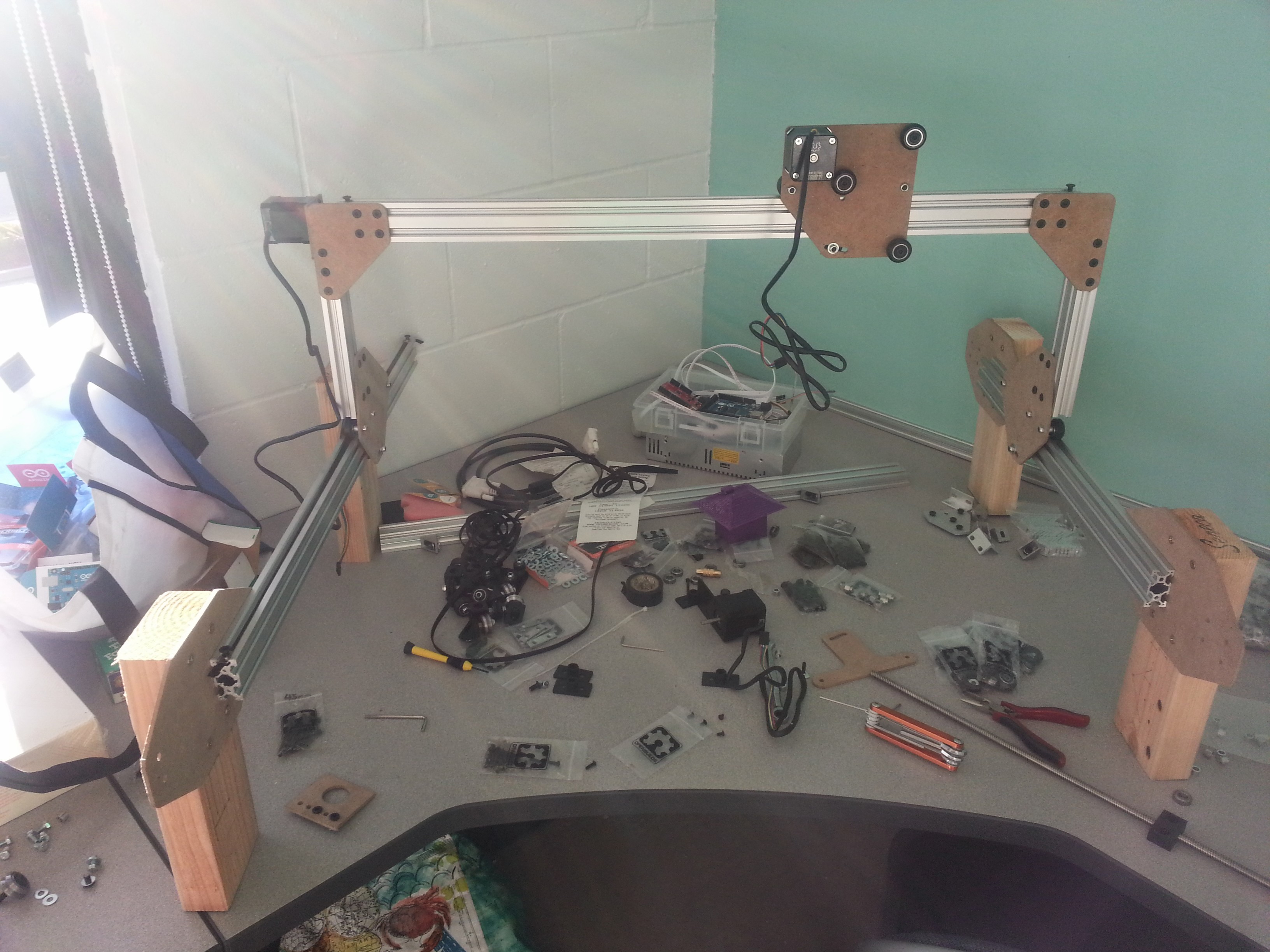

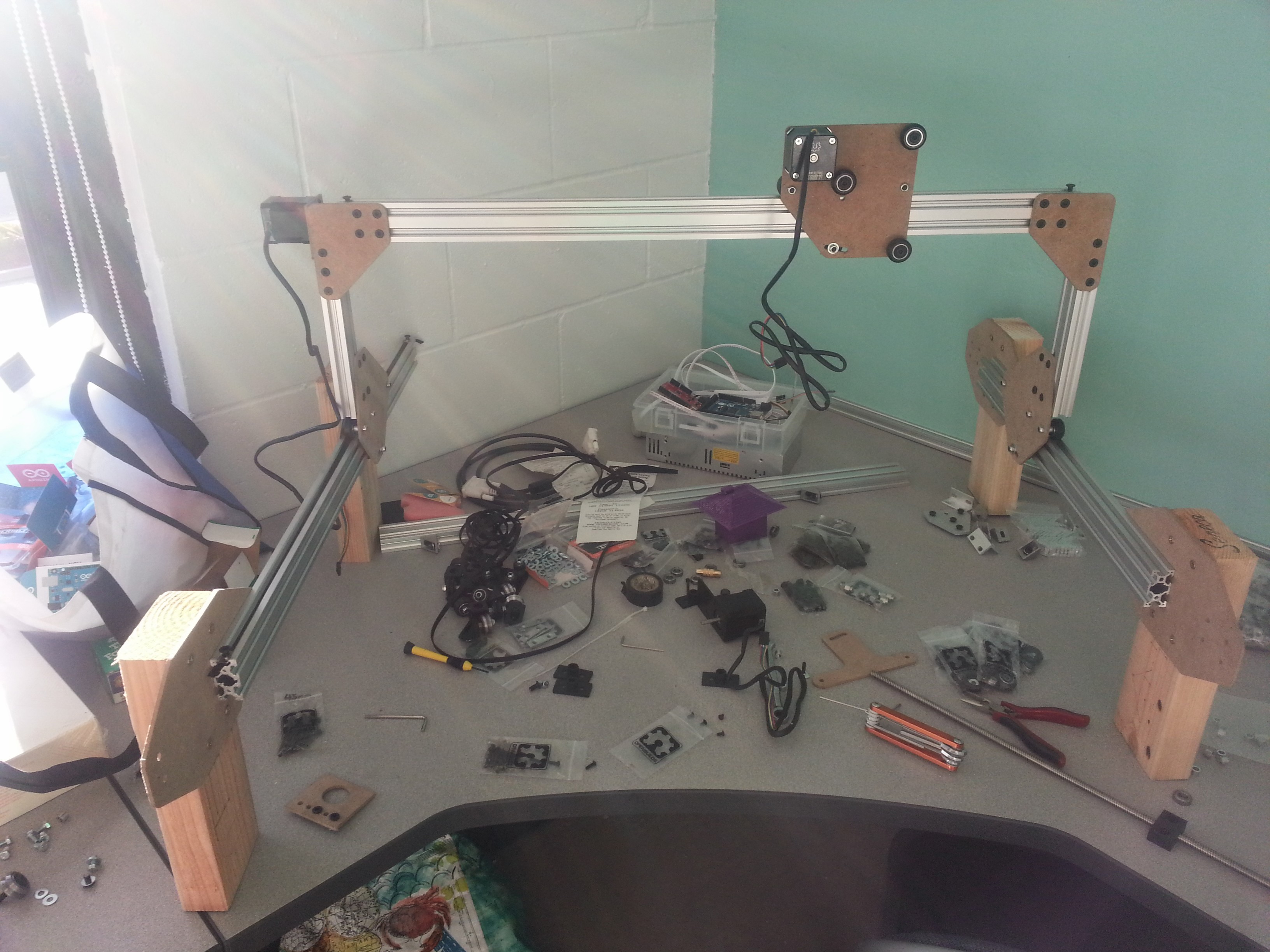

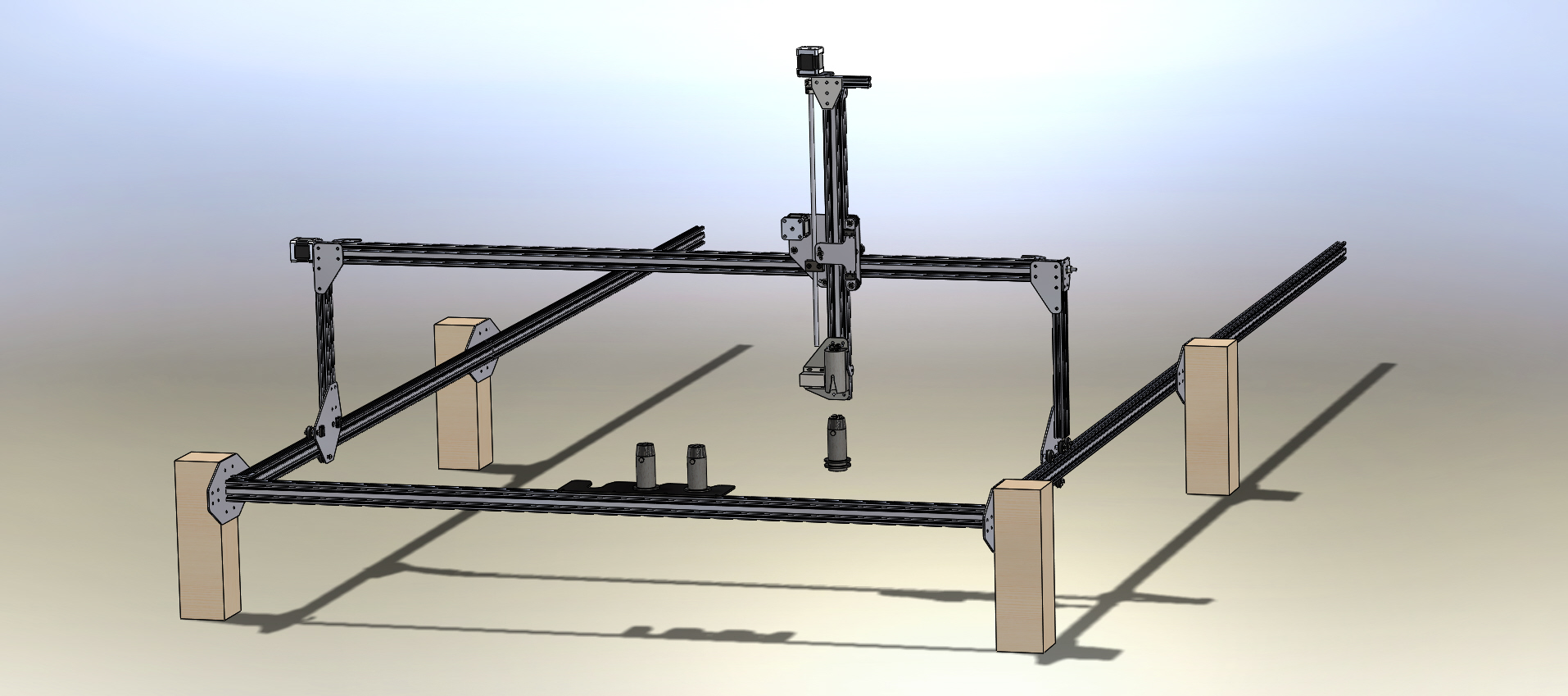

- Design and implementation of custom brackets and plates for greater strength and a more optimized design. These could be produced at home with a drill and a printout, a CNC router, waterjetting, or laser cutter

- Endstop integration to let the microcontroller know when FarmBot is at the end of itself

- Changed from looped belts to belt and pinion style movement for both the X and Y directions, allowing for simpler installation, less belt usage, and keeping all electronic components moving together with the gantry (no motors attached to the tracks)

- Features synchronized belt movement along the tracks via a shaft and a single motor to drive both sides of the gantry

- Began Universal Tool Mount integration with a door locker solenoid rather than all tools attached to the bot at once

- Angled slots for wheel adjustments rather than expensive eccentric spacers

- Z-axis leadscrew is positioned closer to the gantry for less induced torque on the cross-slide and wheels

- Minimization of number of parts and simplification of them providing easier and faster assembly, accessible screw locations, and greater affordability