| Length |

Measure the length of the belt using a measuring tape. |

See BOM spec. |

+/- 1cm |

| Width |

Measure the width of the belt using digital calipers. |

5.8mm |

+/- 0.2mm |

| Extrusion fit |

Lay the belt into the V-slot of an extrusion. |

The belt should pass through the narrowest section and lay flat in the bottom of the slot. |

N/A |

| Pitch |

Measure the distance between one tooth and another one 50 teeth away using digital calipers, then divide by 50. |

2mm |

+/- 0.02mm (1%) |

| Pulley fit |

Engage the belt to a GT2 pulley. |

The belt should fully engage with the pulley’s teeth. |

N/A |

| Thickness |

Measure the thickness of the belt using digital calipers. |

1.25mm |

+/- 0.1mm |

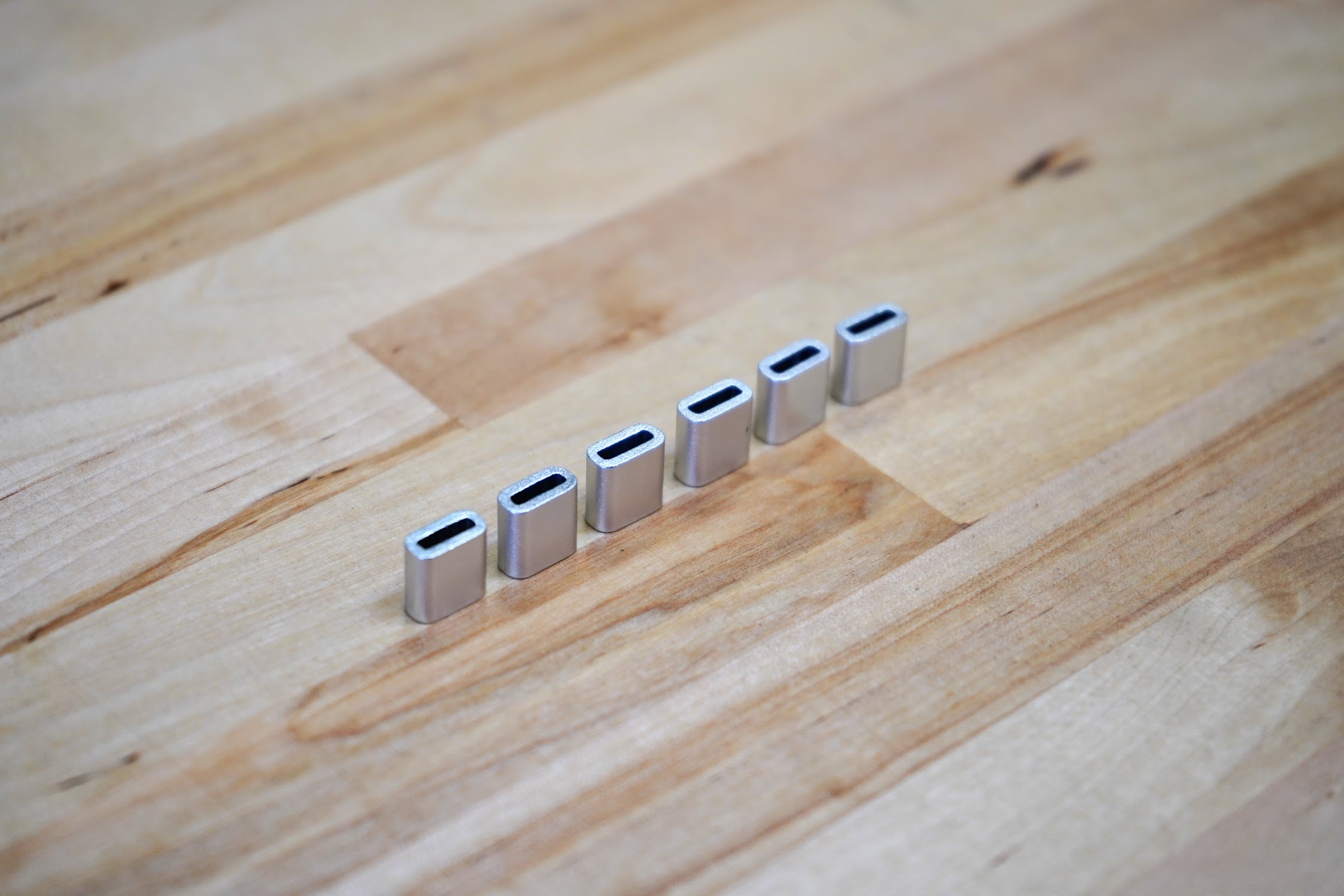

| Belt sleeve fit |

Assemble the belt to a belt clip and secure with a belt sleeve. |

The belt sleeve should fit snugly over the two belt sections and provide adequate holding force. |

N/A |

| Stretch |

Tie a belt to a fixture 1.5m or more off the ground. Mark the belt just below the knot and then add a second mark exactly 1000mm below the first. Hang a 10kg weight from the belt (below the 1000mm mark) and measure the distance between the two marks. |

1000m |

+ 10mm (1%) |

| Strength |

Use a tensile testing machine to measure the equivalent hung weight at which the belt will break. |

100kg |

- 20kg |

| Color |

Inspect the belt for any discoloration or markings |

Black, no markings. |

N/A |