Tracks

Documentation and assembly instructions for the FarmBot Genesis tracks

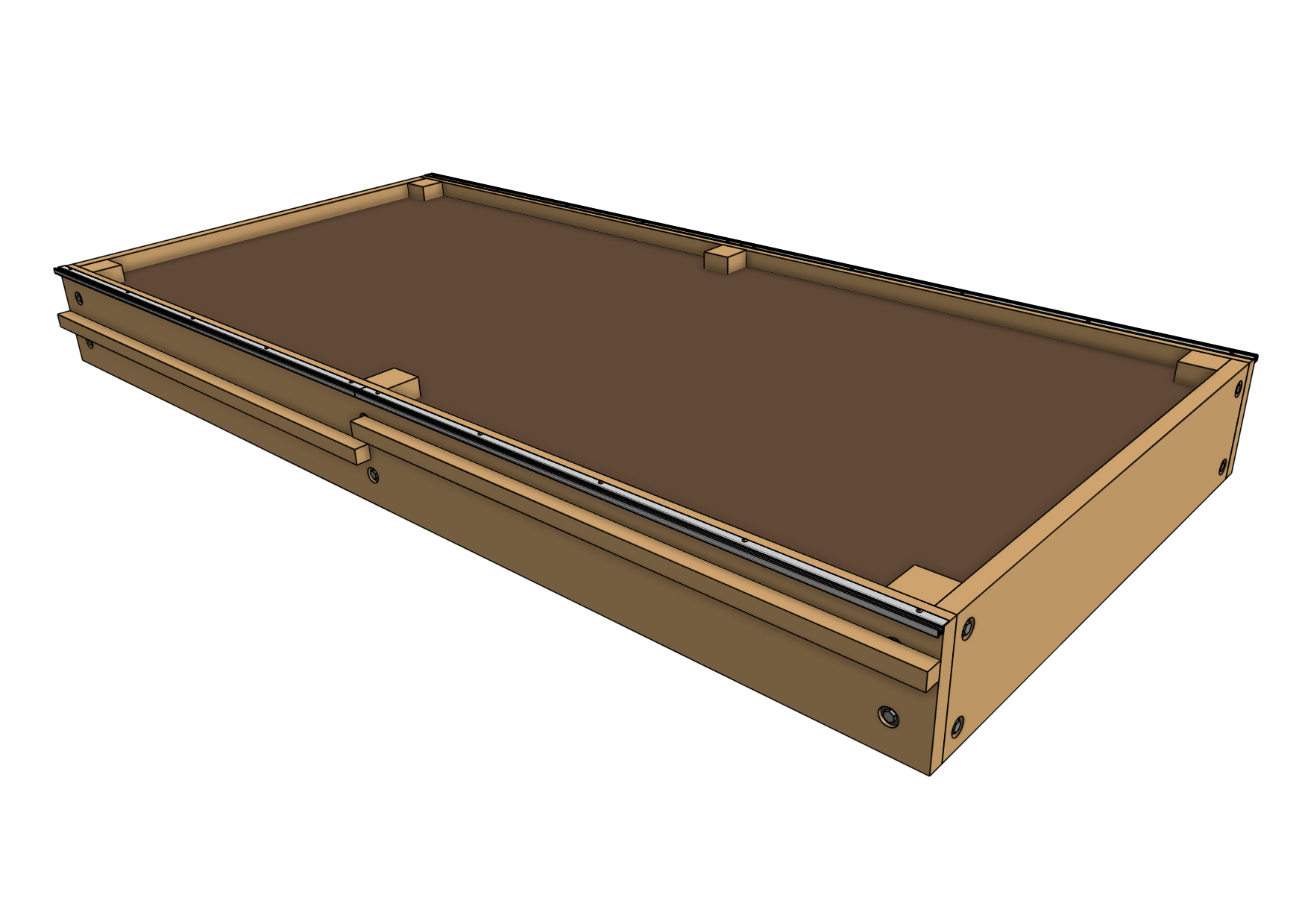

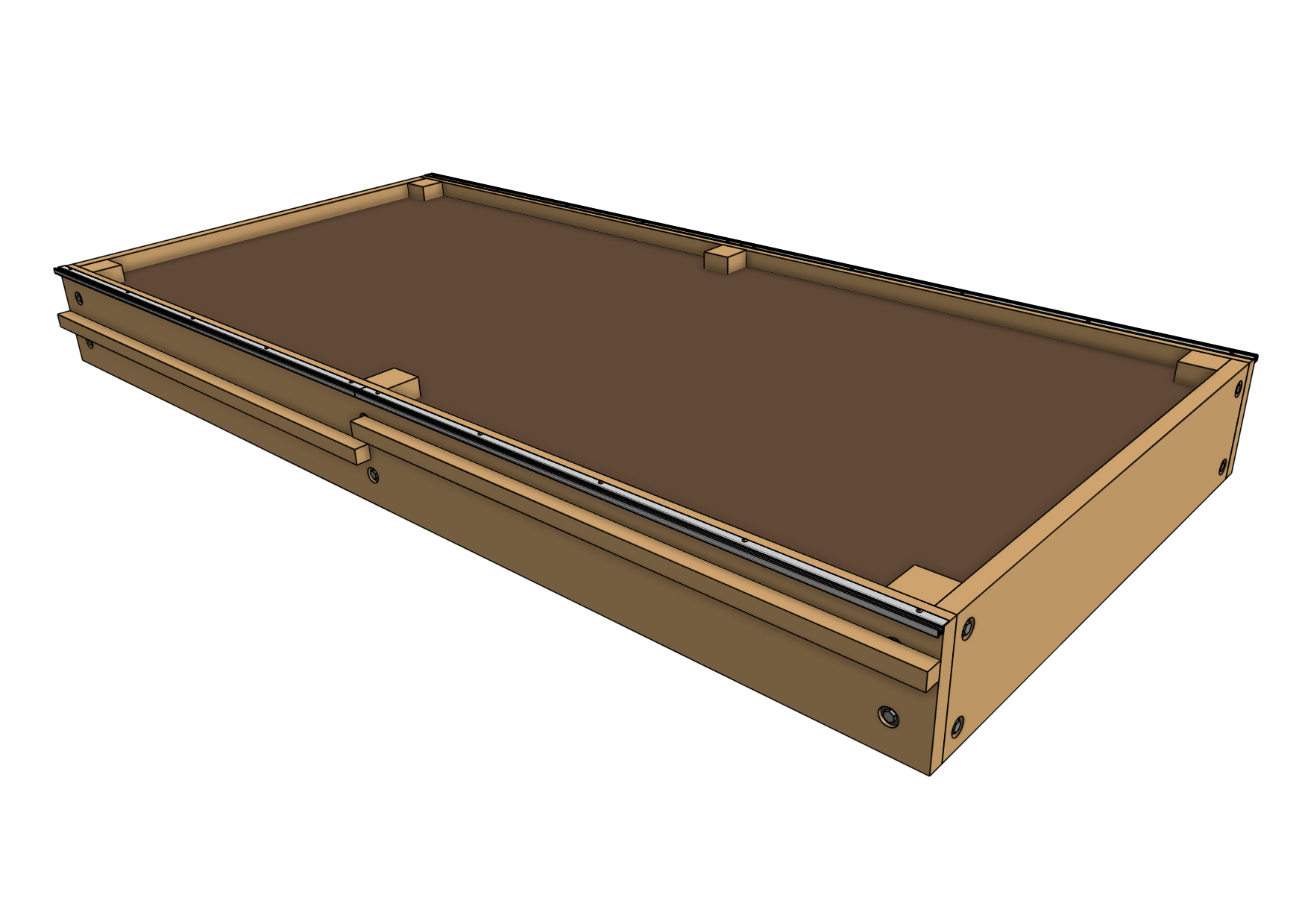

FarmBot’s tracks allow the gantry to move precisely along the x-axis. They are designed to mount directly to the top of a raised bed or similar supporting infrastructure. Each track is composed of 1.5m long aluminum extrusions positioned end-to-end to form a total track length of 3m for Genesis models and 6m for Genesis XL.

30 to 60 minutes

This is the estimated time it will take to assemble the tracks.

The two tracks must be a parallel distance apart such that the gantry may span the distance between them and smoothly move from end to end. Tracks may be spaced closer together than the maximum, in which case you may consider cutting the gantry main beam so that it does not inconveniently extend beyond the tracks. Refer to the maximum supporting infrastructure size table for details on maximum track spacing.

Step 1: Lay out the track extrusions

Handle with care

The aluminum extrusions may have sharp corners and edges.

Lay out all of the track extrusions in the location that you want to attach them to your supporting infrastructure. Make sure that extrusions are fully butted against each other.

Overhang is a-ok

The ends of your tracks do not have to match up perfectly with the ends of your supporting infrastructure. A little overhang or coming up short (when working with a raised bed) is just fine. However, if you need to shorten the tracks (or are interested in lengthening them), see this page for more information.

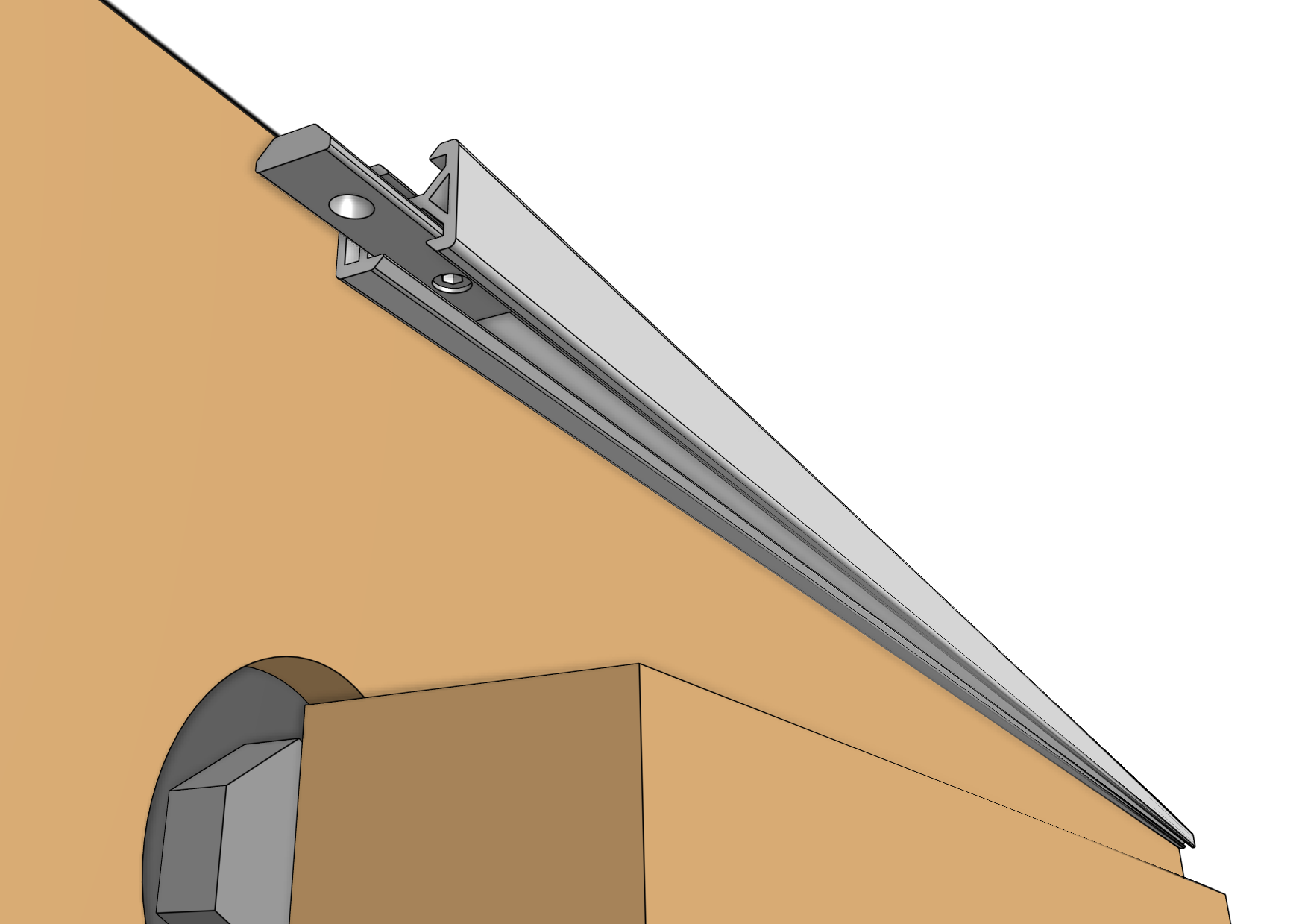

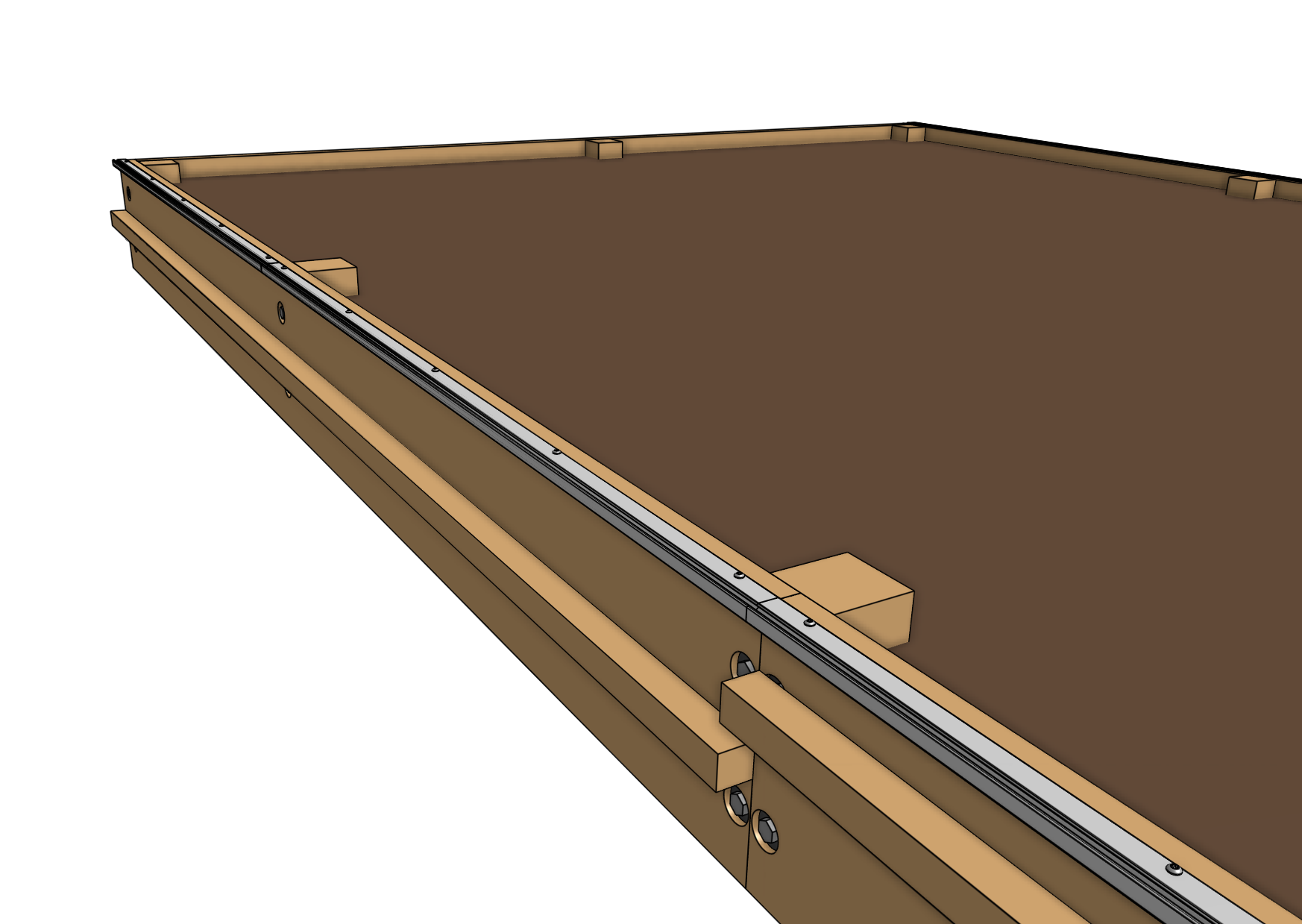

Step 2: Attach the first track extrusion

Attach the first track extrusion to the top of the supporting infrastructure using five wood screws and the provided T25 bit loaded into a drill or driver. The track extrusion should be flush against the side and top of the supporting infrastructure.

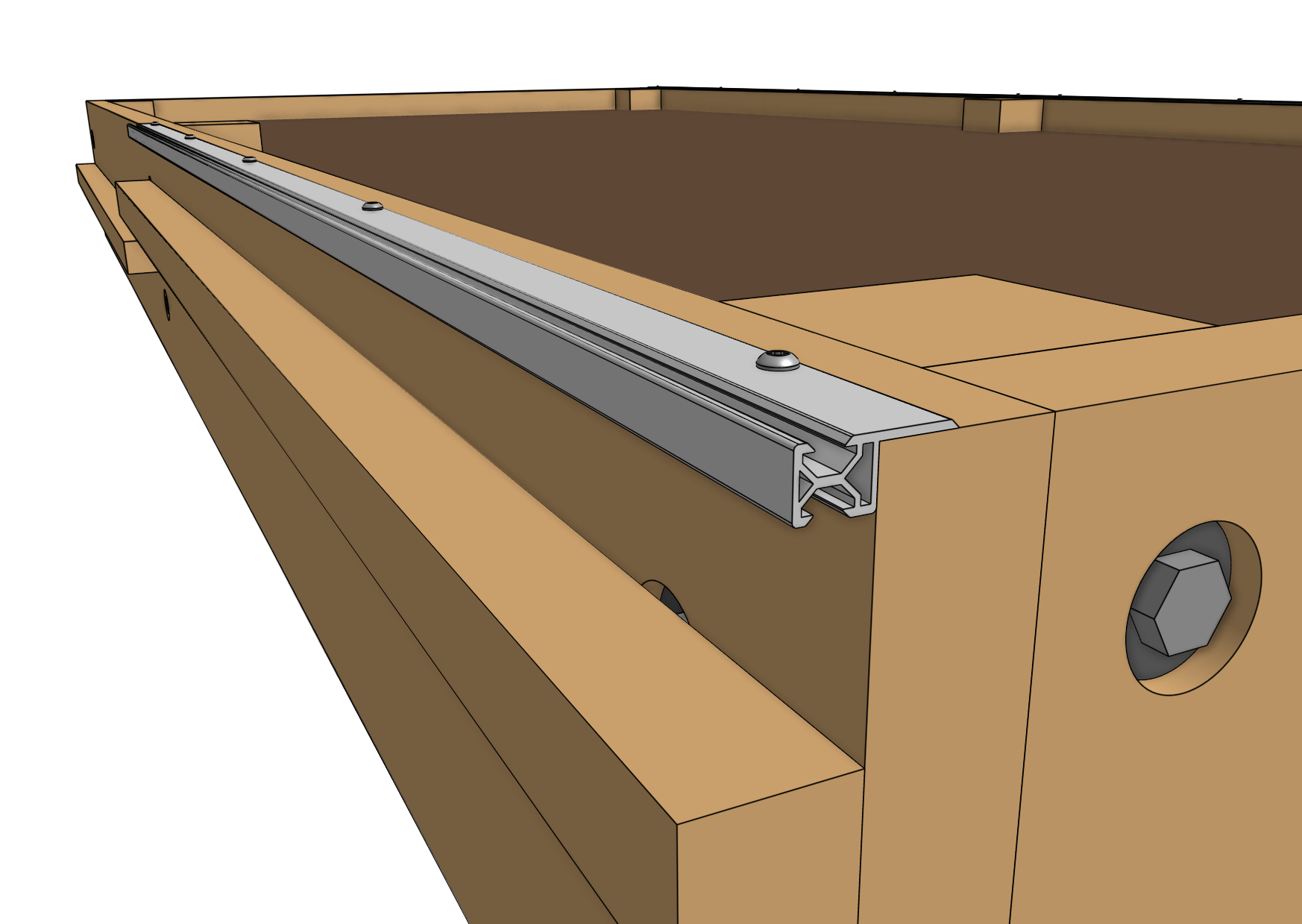

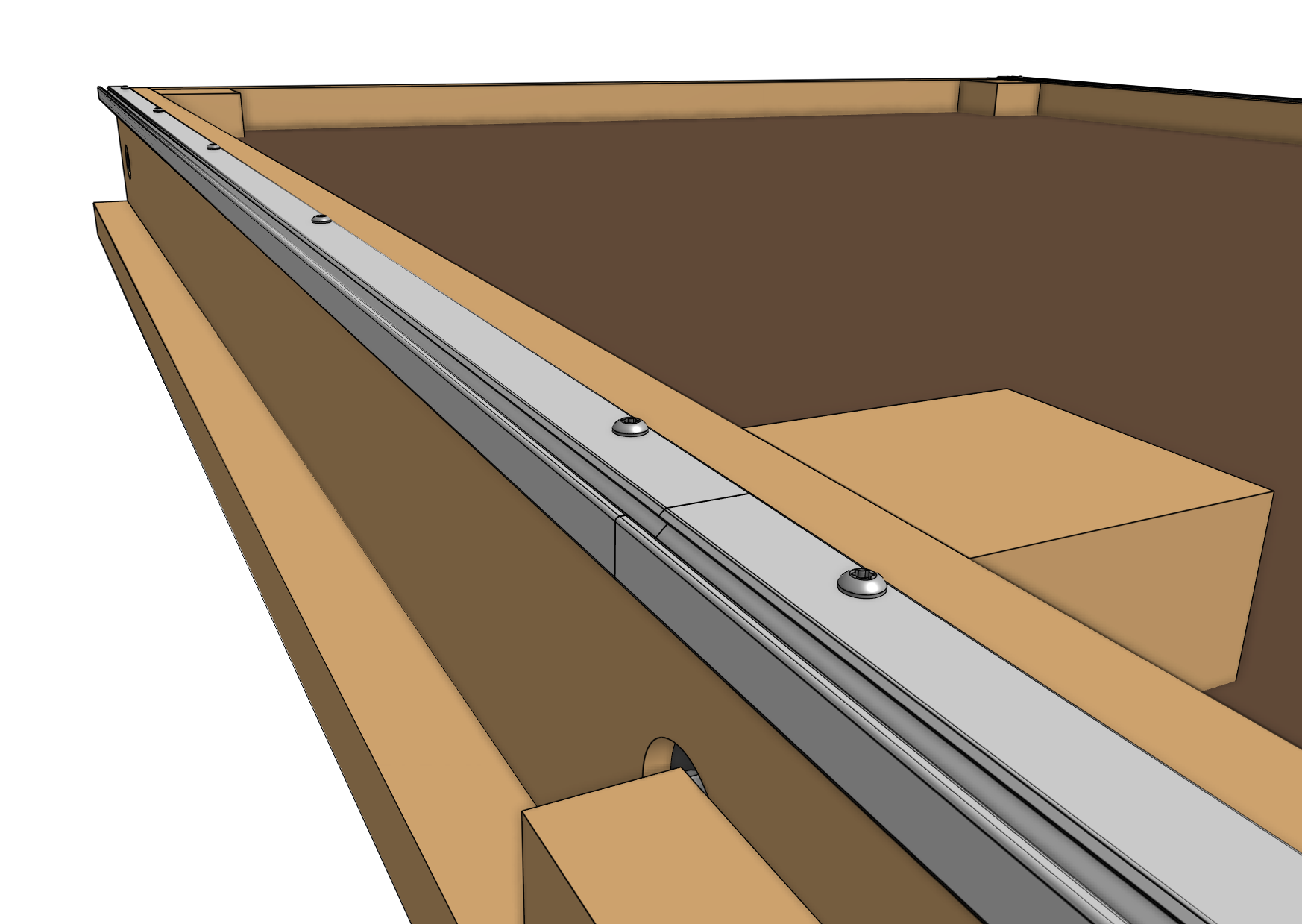

Step 3: Insert a nut bar

Insert a 40mm nut bar halfway into the lower slot of the track extrusion and secure it with an M5 x 4mm setscrew.

Step 4: Attach the next extrusion

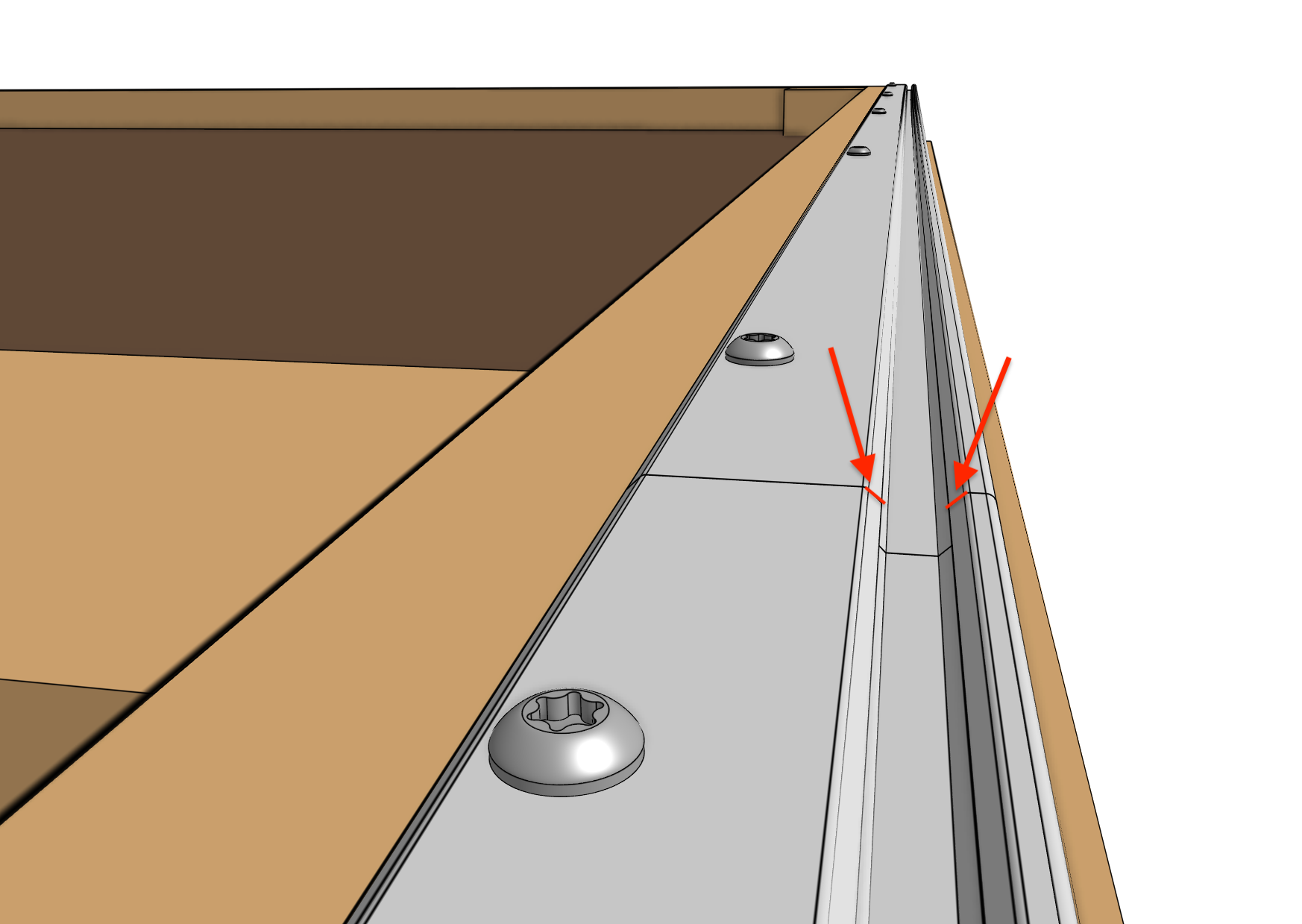

Position the next track extrusion on top of the supporting infrastructure and slide it towards the first extrusion such that the nut bar inserts into the lower slot. With the second extrusion butted up against the end of the first extrusion, secure it to the supporting infrastructure with five wood screws.

Then secure the two extrusion ends together with a second M5 x 4mm setscrew in the nut bar.

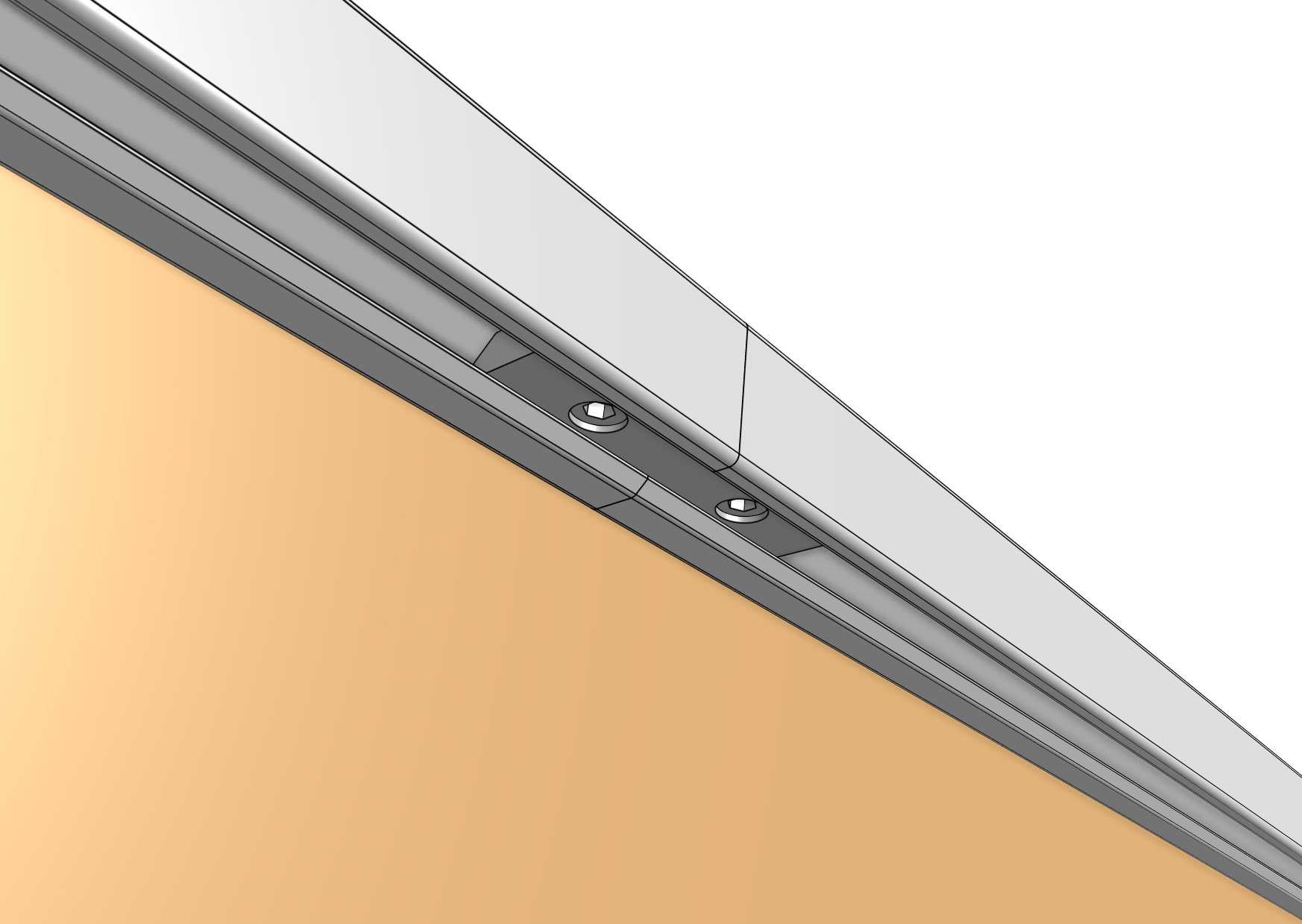

Extrusion alignment is key

Ensure the track extrusions are positioned tightly together at the joint. The top and bottom of the extrusions, as well as the angled V faces must be flush so that the gantry can move across the tracks smoothly.

Step 5: Attach remaining extrusions

This step applies to XL kits only

If you have a standard sized Genesis kit (3m long), proceed to the next step.

Repeat steps 3 and 4 twice to attach two more track extrusions using nut bars, setscrews, and wood screws.

Step 6: Install the other track

Repeat steps 2 through 5 for the track on the other side of the bed.

Parallel or bust

It is critical that the two tracks are parallel throughout the full length of the bed. Measure the distance between the two tracks at various locations along the tracks to ensure the distance is consistent. Use shims or other spacers to better align the tracks in case your supporting infrastructure is not perfect.

If the tracks deviate by more than about 1cm (0.5”), your FarmBot will have trouble moving throughout the full length of the tracks.

Step 7: Sand away bumps

If needed, use 150 grit sand paper to sand away any bumps on the diagonal surfaces of the extrusions that the FarmBot wheels ride upon. This will ease the movements of the FarmBot and improve longevity.

Make sure both the upper and lower diagonal surfaces are smooth to the touch and that there are no bumps or uneven edges in the transition from one extrusion to another.