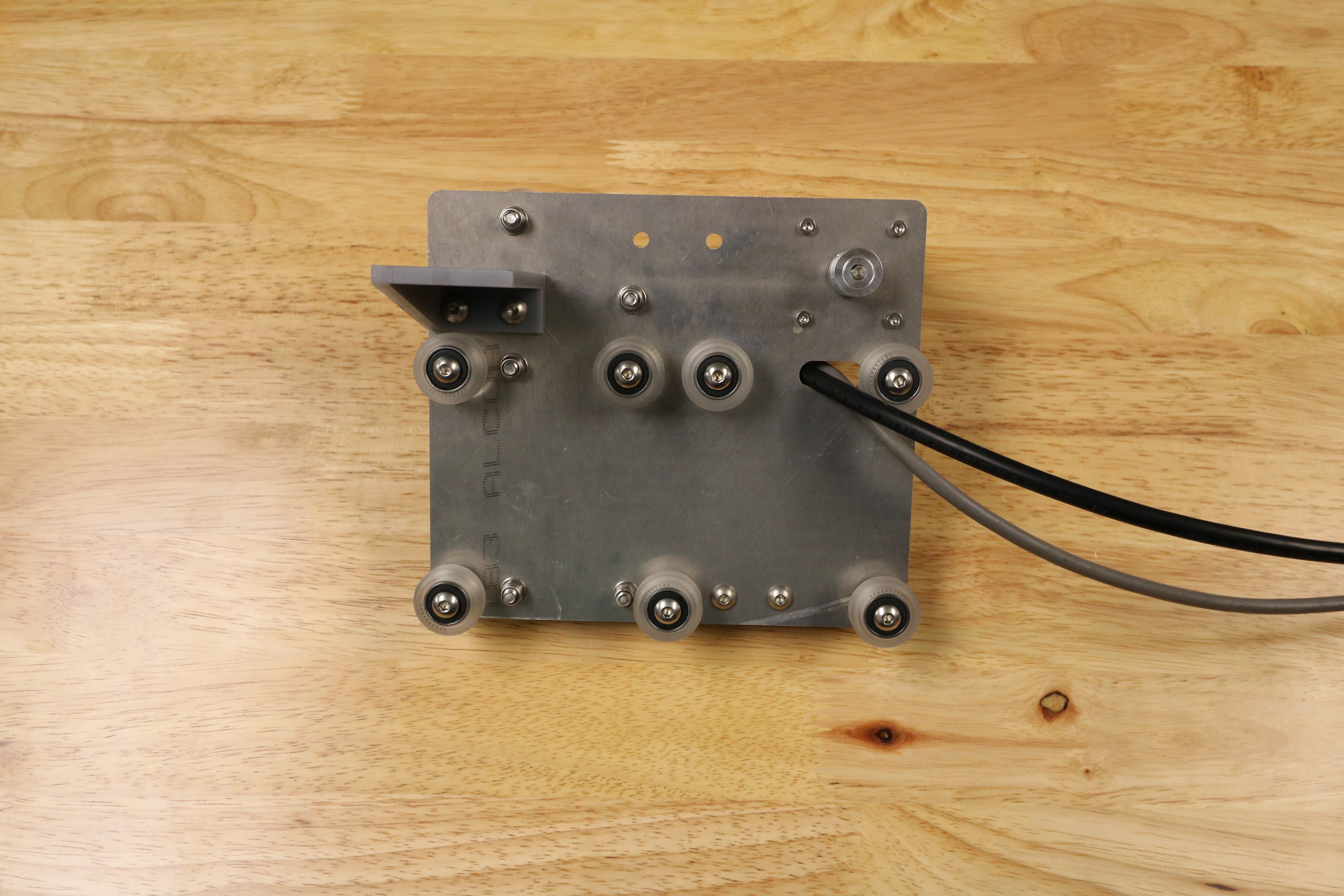

Cross-Slide

Documentation and Assembly Instructions for the FarmBot Genesis Cross-Slide

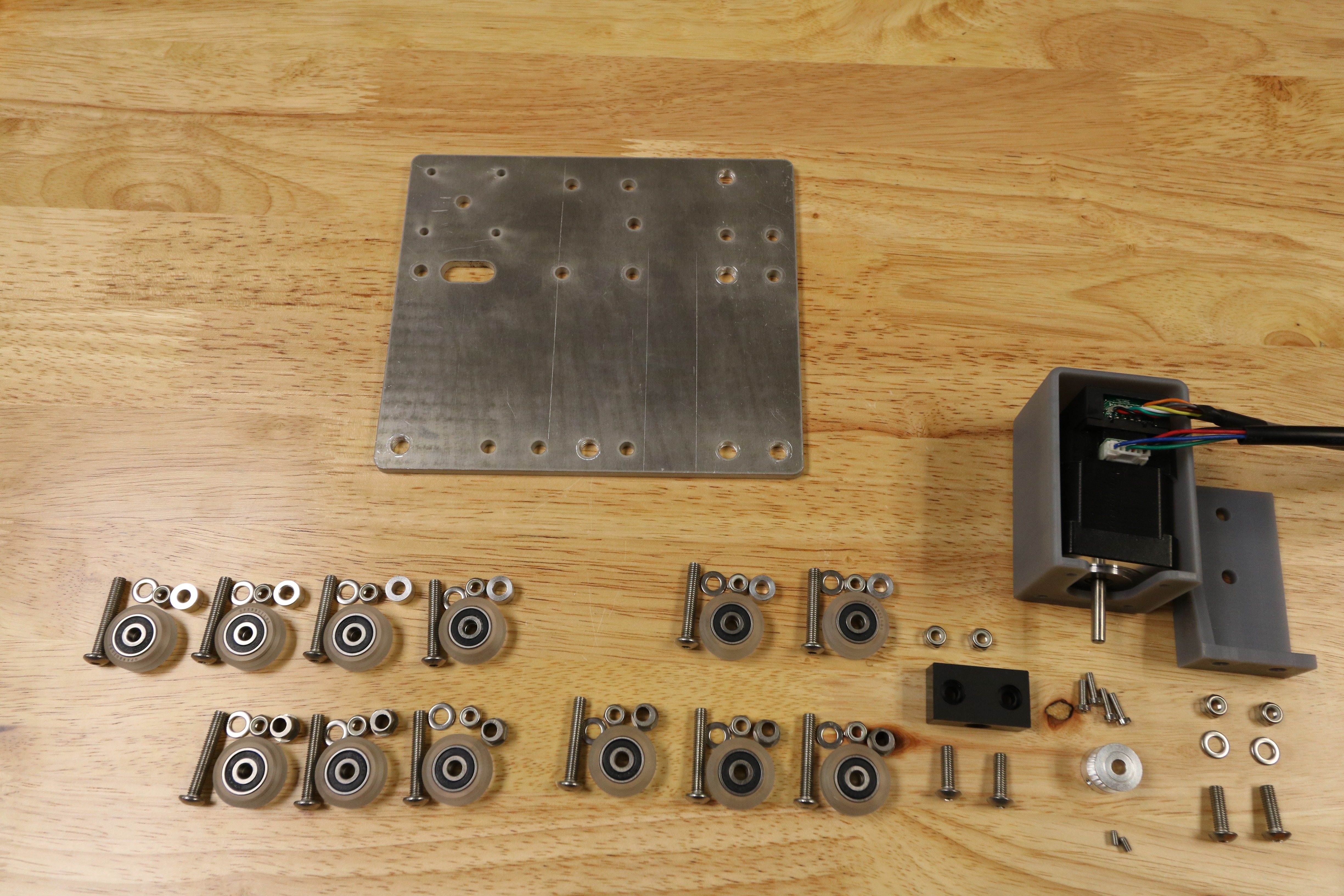

Component List

To prepare for assembly, gather all the components from the table below and lay them out in a logical manner. To complete the assembly in the next pages, you will also need the following tools:

- 3mm hex (allen) wrench

- 8mm wrench

Note: Not all required parts are shown in this image.

| Qty. | Component |

|---|---|

| 1 | Cross-Slide Plate |

| 2 | M3 x 5mm Setscrews |

| 4 | M5 x 16mm Screws |

| 12 | M5 x 30mm Screws |

| 6 | M5 x 6mm Spacers |

| 6 | 6mm Eccentric Spacers |

| 14 | M5 Washers |

| 16 | M5 Locknuts |

| 1 | Horizontal Motor Housing |

| 1 | Long Cable Carrier Mount |

| 12 | Complete V-Wheels (one polycarbonate wheel, two 16 x 5 x 5mm ball bearings, and one 10 x 5 x 1mm shim) |

| 1 | Leadscrew Block |

| 1 | NEMA 17 Stepper Motor and Rotary Encoder with 2500mm length cables |

| 1 | 20 tooth GT2 Pulley |

| 2 | Belt Clip Plates |

| 1 | Y-Axis Belt |

| 2 | M3 x 10mm Screws |

Change Log

- Horizontal motor housing has been completely re-designed to better protect the ends of the motor and the rotary encoder from rain.

- Flipped the orientation of the long drag chain mount and added a gusset for support.

- Increased the size of the slot on the cross-slide for the motor and encoder wires to be passed through more easily.

- Increased the tolerance of the eccentric spacer holes on the cross-slide plate.

- Switched to button head M5 screws.

- Increased the cross-slide plate width by 10mm to accommodate the larger z-axis cable carrier and adjusted the mounting holes accordingly.

- Added a V-wheel with eccentric spacer to the middle of the bottom edge of the cross-slide plate for added strength in the connection with the gantry main beam.

Room for Improvement

- The Z axis cable carrier mounting holes could be changed to a slot to allow for more flexibility with which cable carrier to use, and where exactly it is mounted on the plate

- Explore a bent metal plate version of the long drag chain mount