Attach the Drivetrain

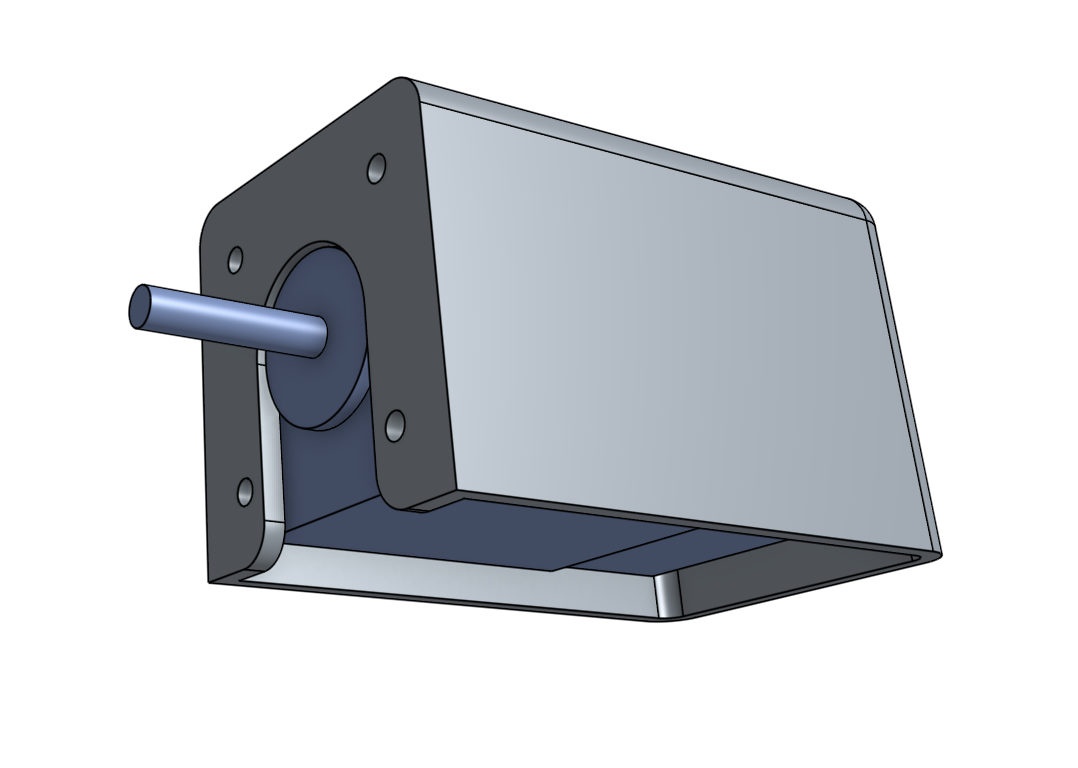

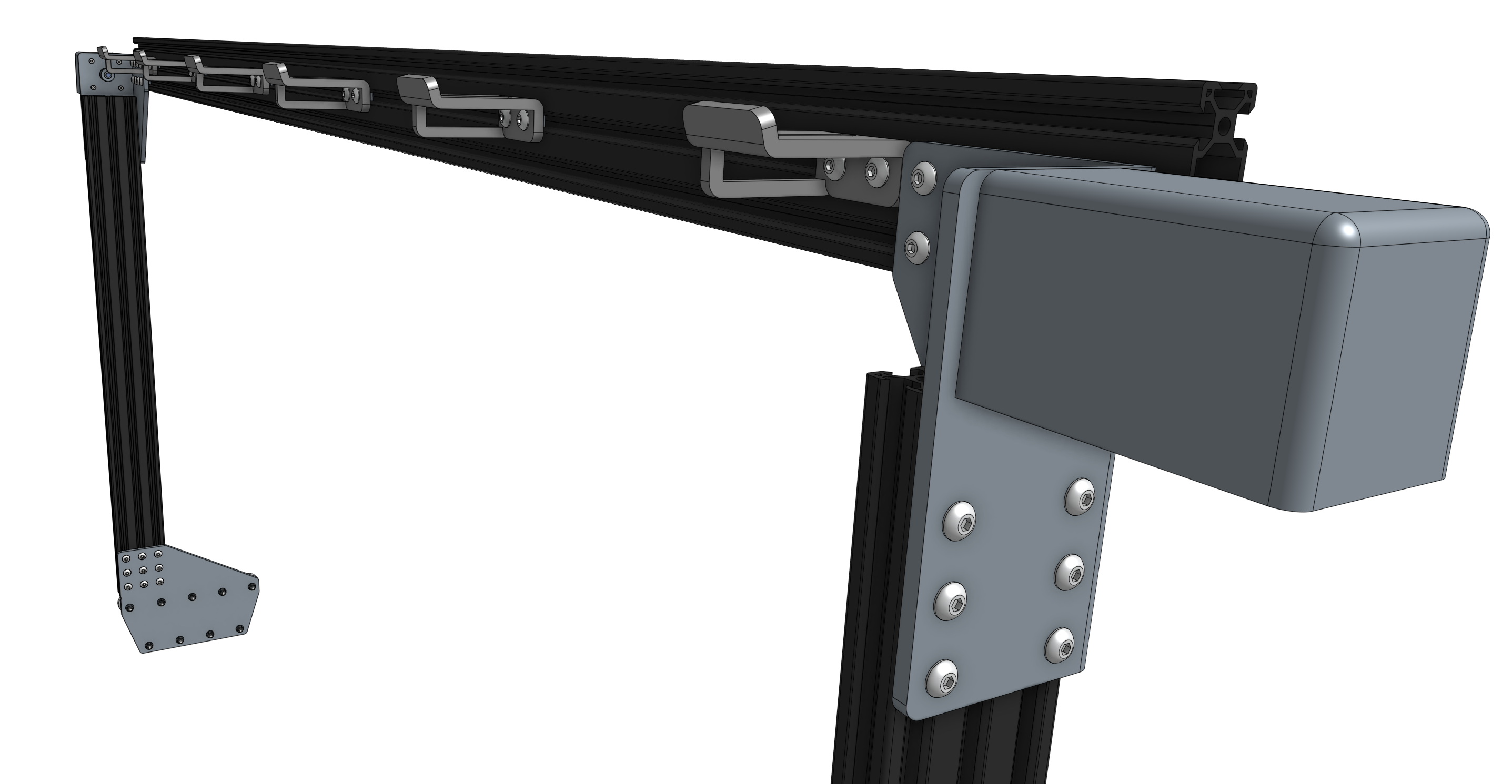

Step 1: Attach the gantry motors

For this step you will need:

- Two NEMA 17 stepper motors with rotary encoders

- Two horizontal motor housings

- Eight M3 x 16mm screws

- The 2mm and 3mm hex drivers

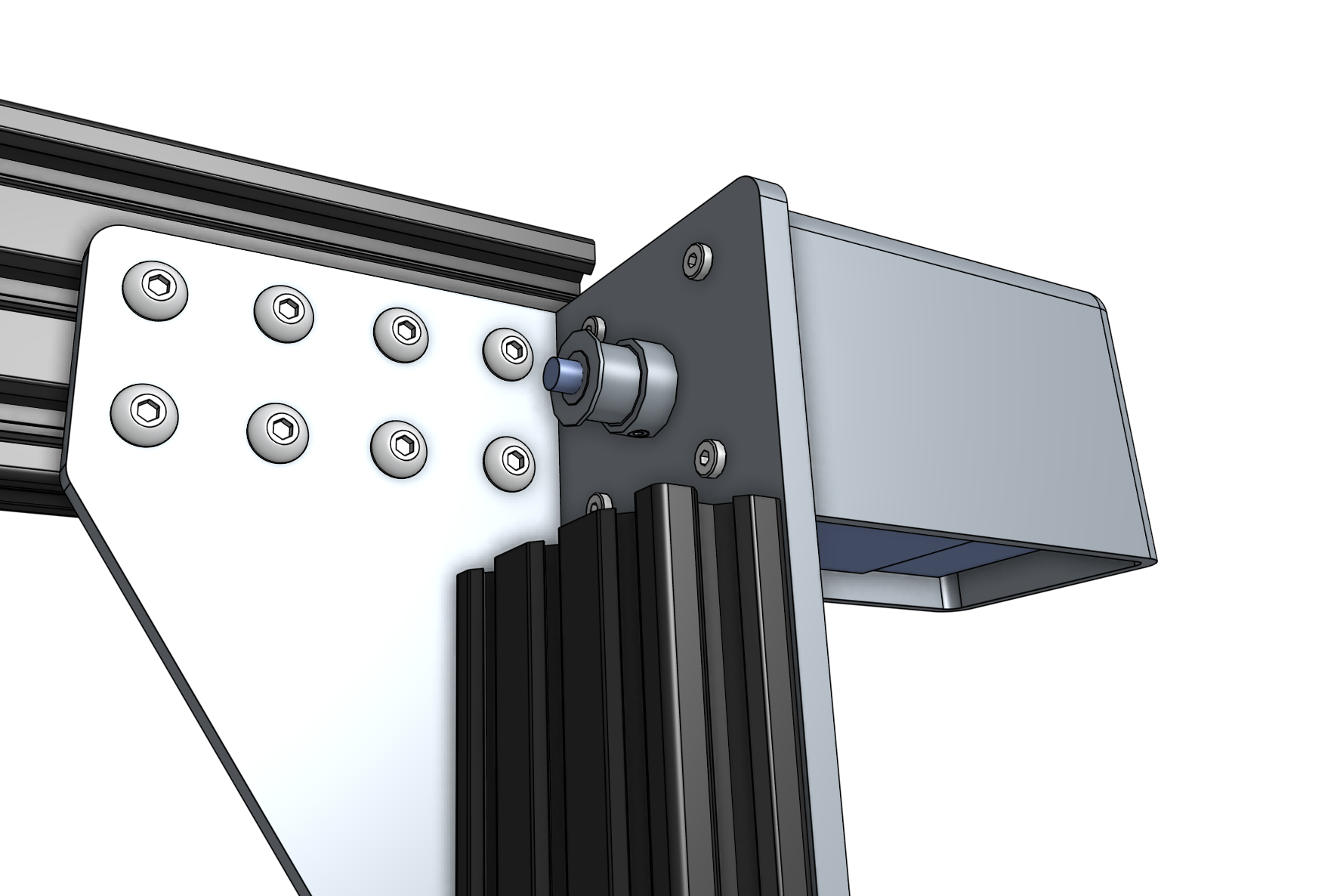

Slide a motor into a horizontal motor housing, ensuring that the shaft of the motor is coming out of the housing and that the motor and encoder’s wires are facing down through the open bottom of the housing.

Position the motor and housing onto the gantry corner bracket and attach it with four M3 x 10mm screws.

Slide a GT2 pulley onto the motor shaft and tighten it using the two M3 setscrews and the 2mm hex driver.

Repeat the above steps for the second motor on the other gantry corner bracket.

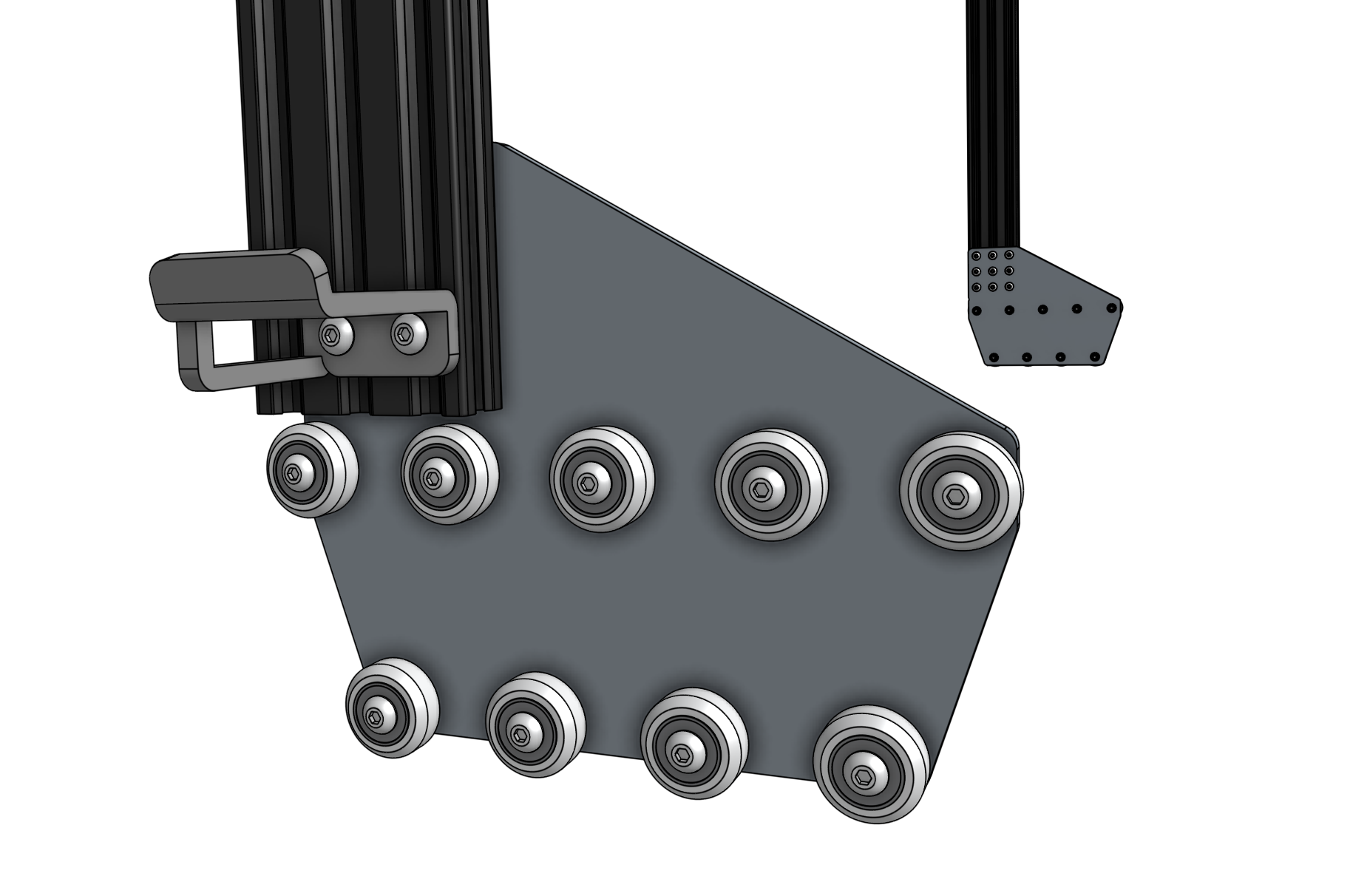

Step 2: Install the cable carrier supports

Attach six cable carrier supports to the back side of the gantry main beam using two M5 x 10mm screws and M5 tee nuts for each support. The supports should reside in the middle slot of the main beam extrusion and be equally spaced along its length.

Attach one more cable carrier support to the left-side gantry column using two M5 x 10mm screws and M5 tee nuts.