Z-Axis Cable Carrier

- Step 1: Prepare the cable carrier

- Step 2: Orient the cable carrier

- Step 3: Lay out the tubing and wiring

- Step 4: Snap in some tabs

- Step 5: Mount the cable carrier to the cross-slide

- Step 6: Attach the vertical cable carrier supports

- Step 7: Mount the cable carrier to the z-axis

- Step 7: Feed the z-axis motor and encoder cables

- Step 8: Add the vertical motor housing

- Step 9: Snap in the remaining tabs

- What’s next?

Step 1: Prepare the cable carrier

Remove all of the snap-in tabs from the z-axis cable carrier. The z-axis cable carrier is the shortest cable carrier in the kit with 37 links in it (740mm) + end pieces.

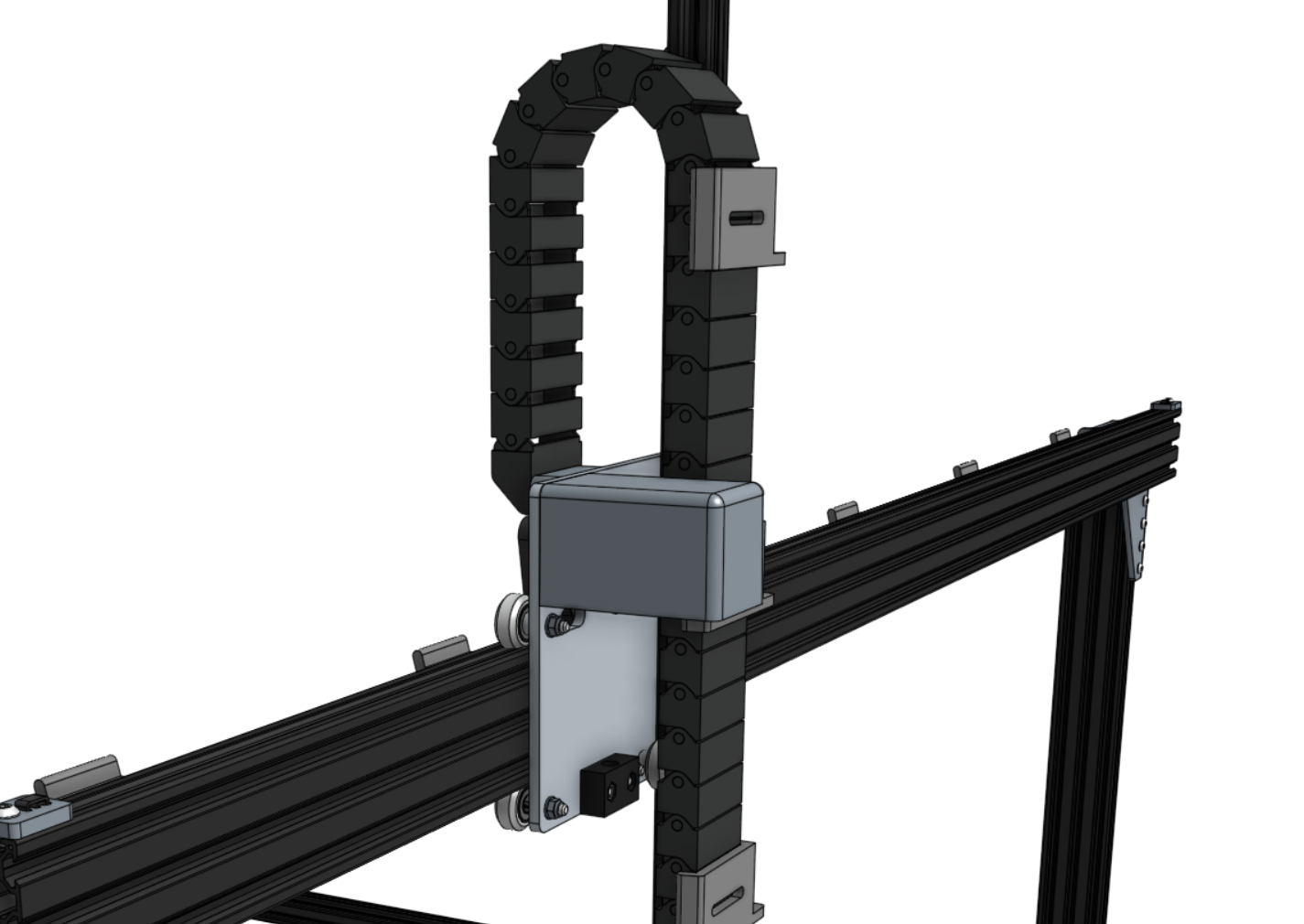

Step 2: Orient the cable carrier

There is only one orientation that the z-axis cable carrier mounts to the cross-slide and z-axis, and it is determined by the orientation of the end pieces. Inspect the images below to see how the cable carrier will be mounted, but do not attach it at this time.

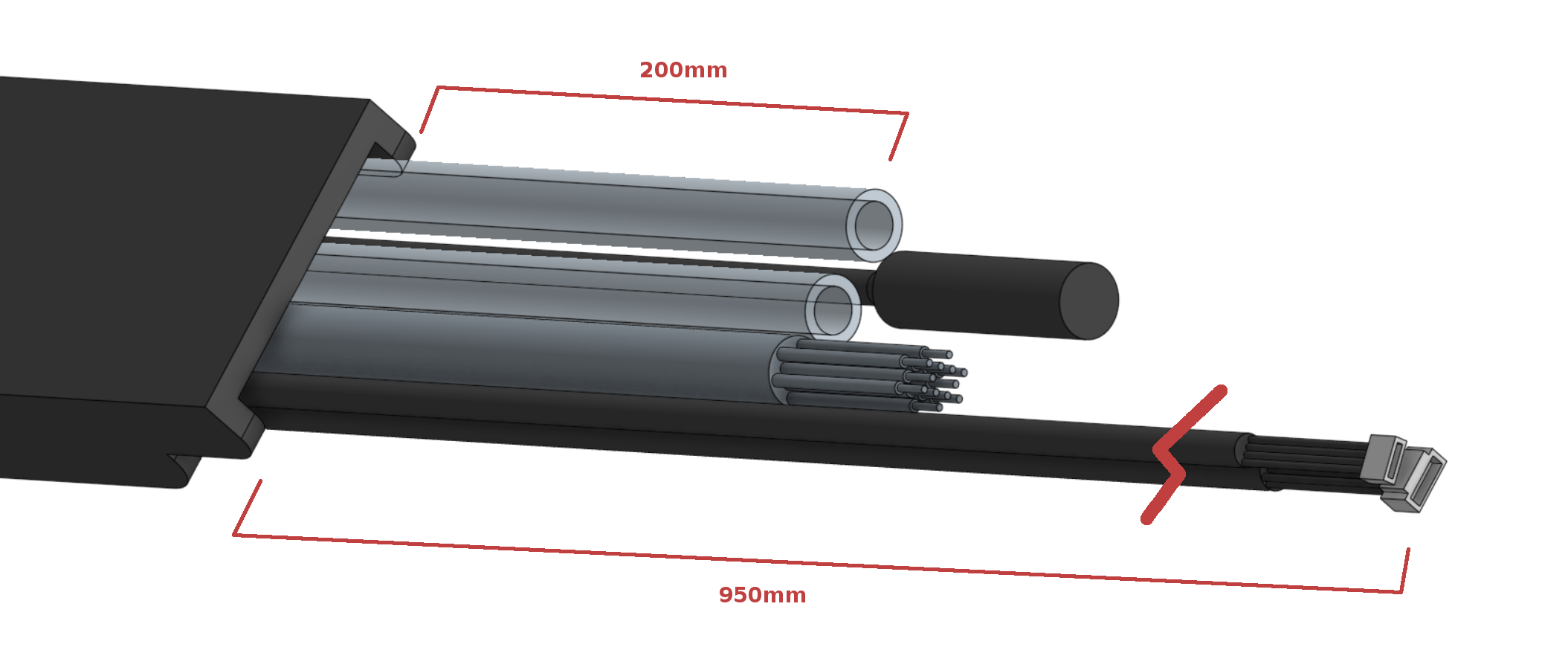

Step 3: Lay out the tubing and wiring

Keeping the mounting orientation of the cable carrier in mind, lay the UTM cable, the two liquid/gas tubes, the camera cable, and the z-axis motor and encoder cables into the open cable carrier. The ends of everything should be offset from the end of the cable carrier as follows:

- The ends of the tubes should extend 10cm beyond the end of the cable carrier.

- The end of the UTM cable with bare wire ends (no connectors) should extend 10cm beyond the end of the cable carrier.

- The end of the camera should extend 15cm beyond the end of the cable carrier.

- The end of the z-axis motor cable with the white plug that connects to the motor should extend 100cm beyond the end of the cable carrier.

- The end of the z-axis encoder cable with the white plug that connects to the encoder should extend 100cm beyond the end of the cable carrier.

Image of the extra lengths

Organization is important!

When laying the cables and tubing in the carrier, ensure that none of the cables or tubes criss-cross over each other. If they do, you will have trouble snapping in the tabs and you risk compressing the tubes and preventing air/water flow.

Step 4: Snap in some tabs

Snap in three cable carrier tabs at both ends of the cable carrier, and five more spread throughout the middle of the cable carrier so that as you mount the assembly, the cables and tubing will stay in place. You do not want to snap in all of the tabs at this time because that will make it difficult to adjust any of the tubes or cables if needed.

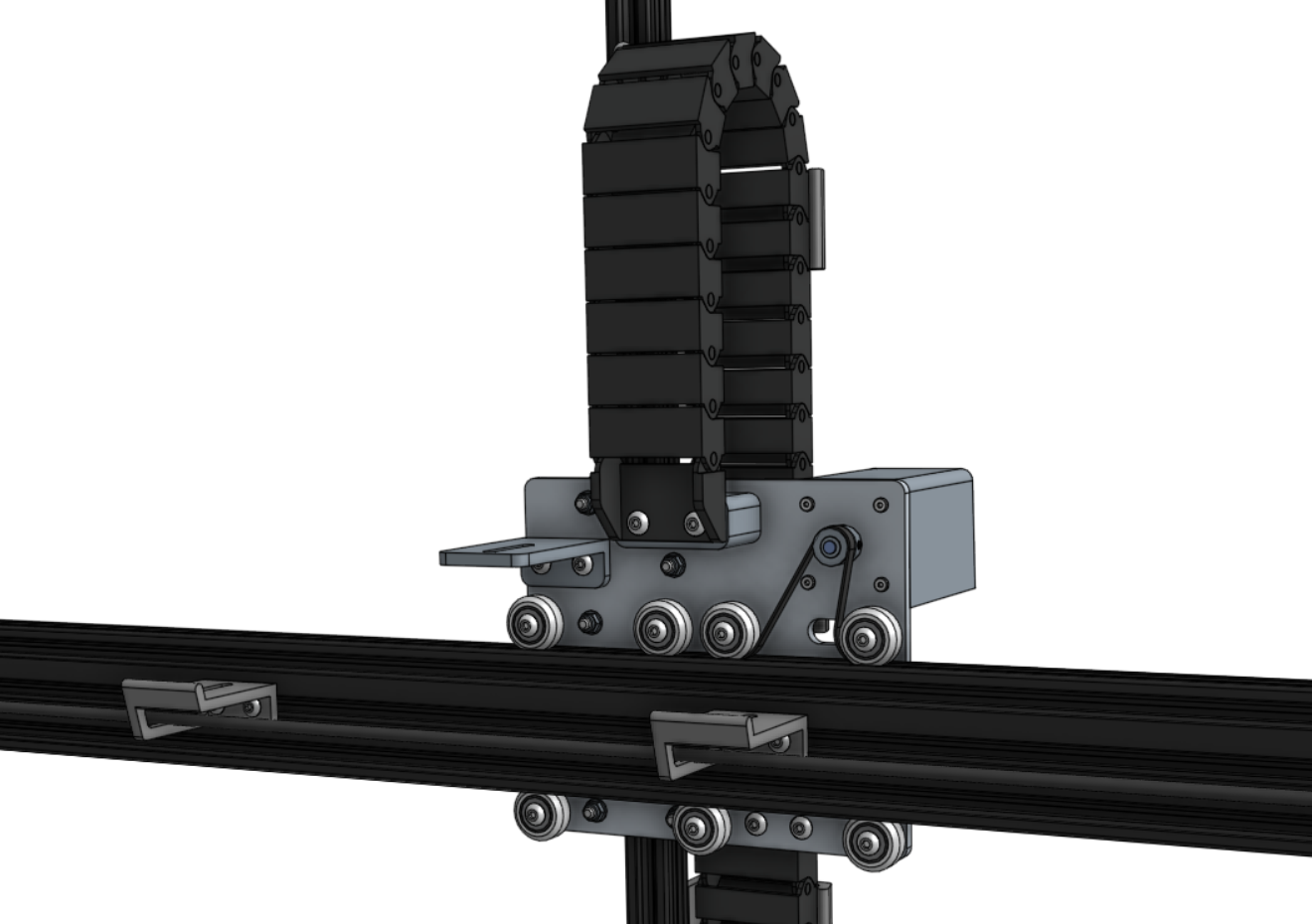

Step 5: Mount the cable carrier to the cross-slide

Carefully lift the cable carrier assembly and drape it over the cross-slide.

Attach the cable carrier to the cross-slide using two M5 x 45mm screws, M5 washers, M5 locknuts, and the cable carrier spacer block. The screws should thread firmly through the cable carrier end pieces.

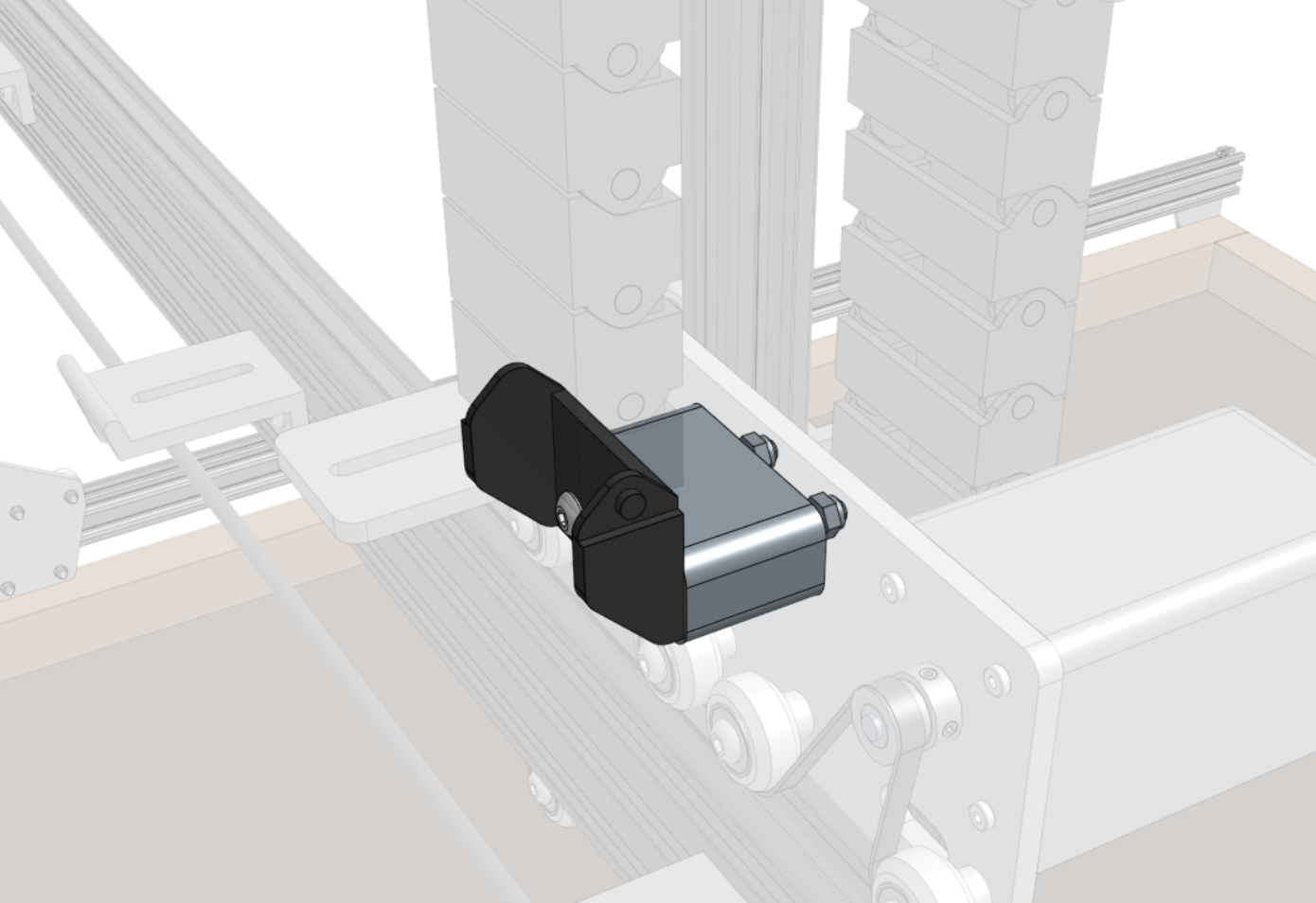

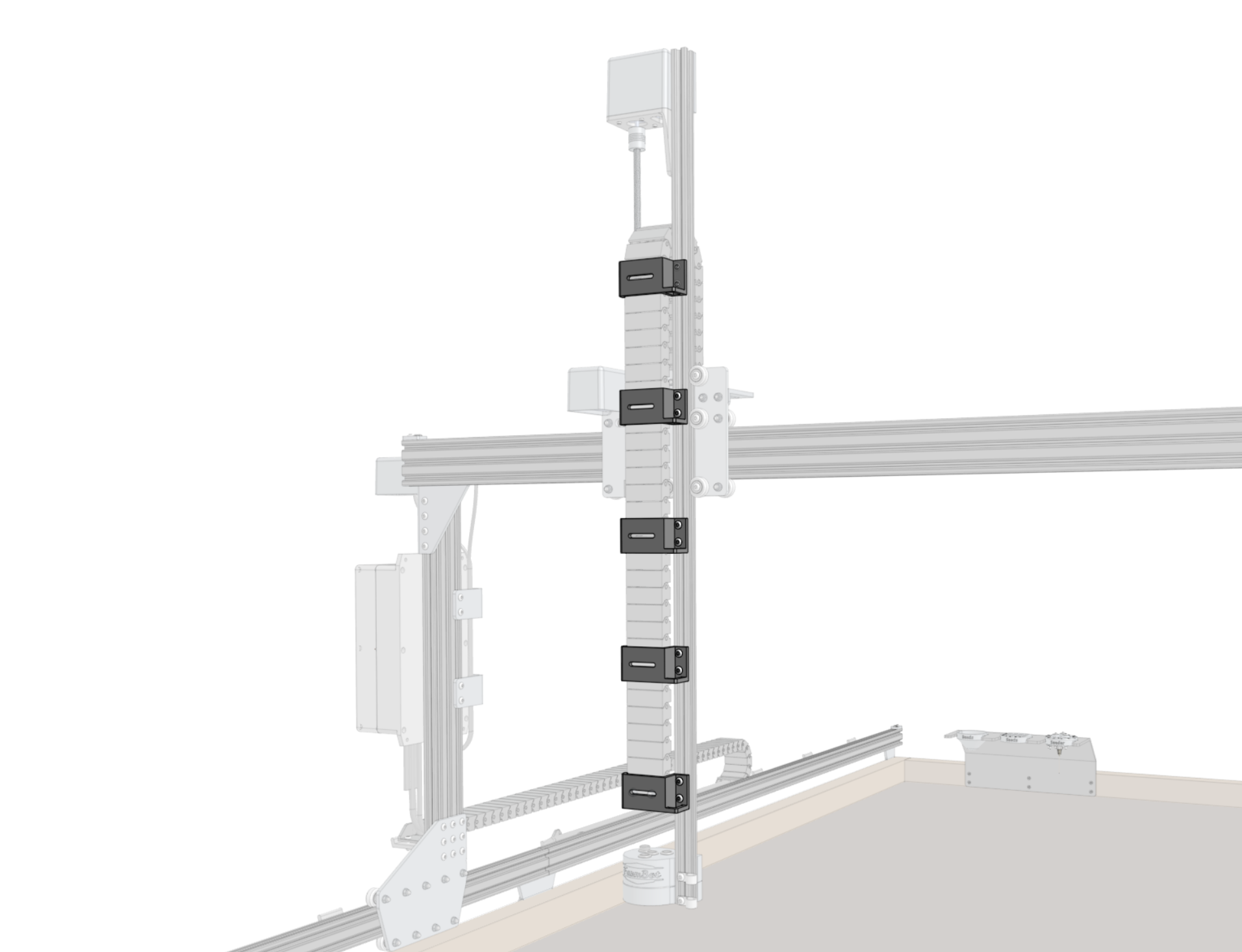

Step 6: Attach the vertical cable carrier supports

Use two M5 x 10mm screws and M5 tee nuts to attach each of the five vertical cable carrier supports to the z-axis extrusion. Space the supports evenly along the extrusion as shown.

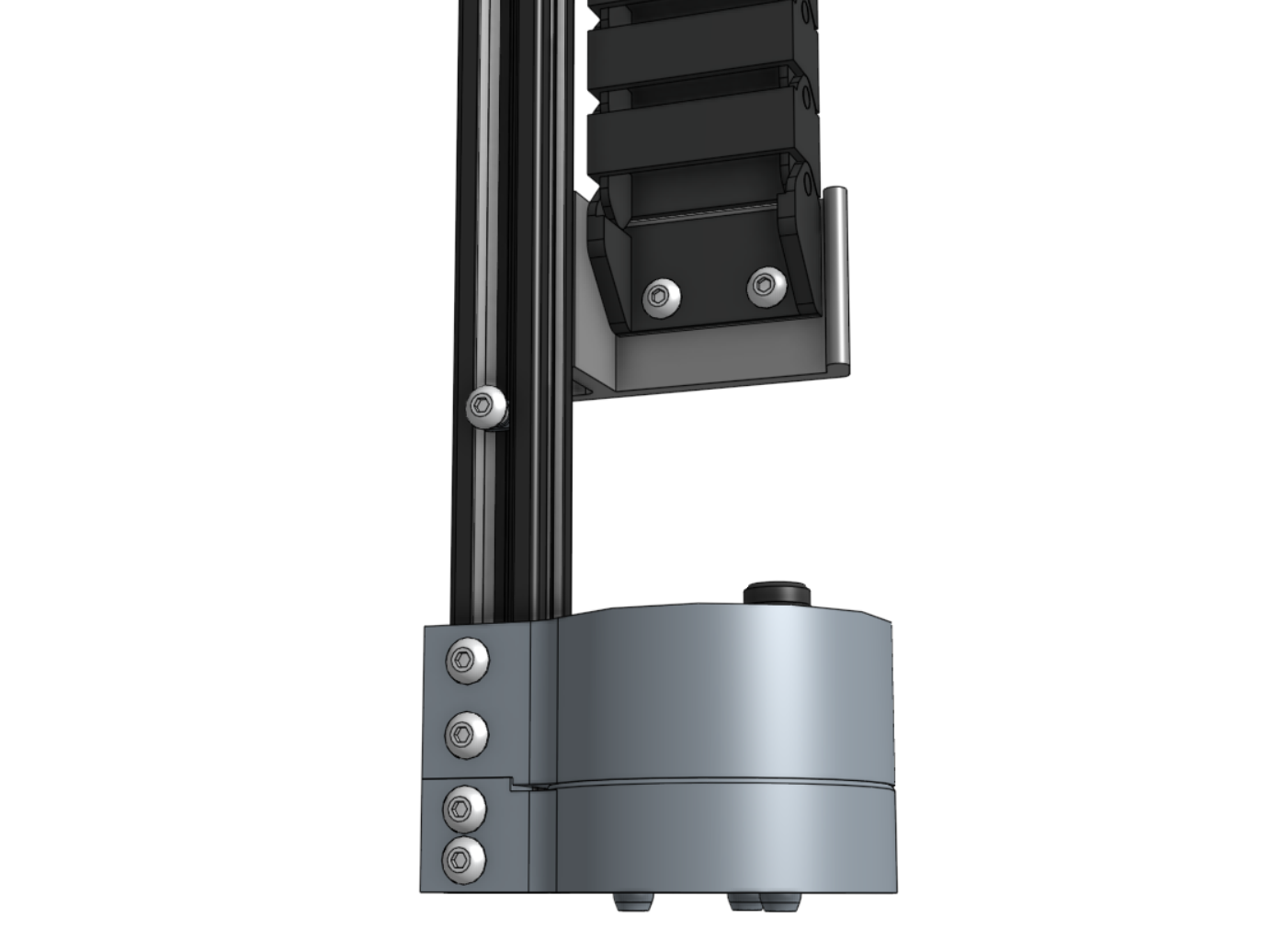

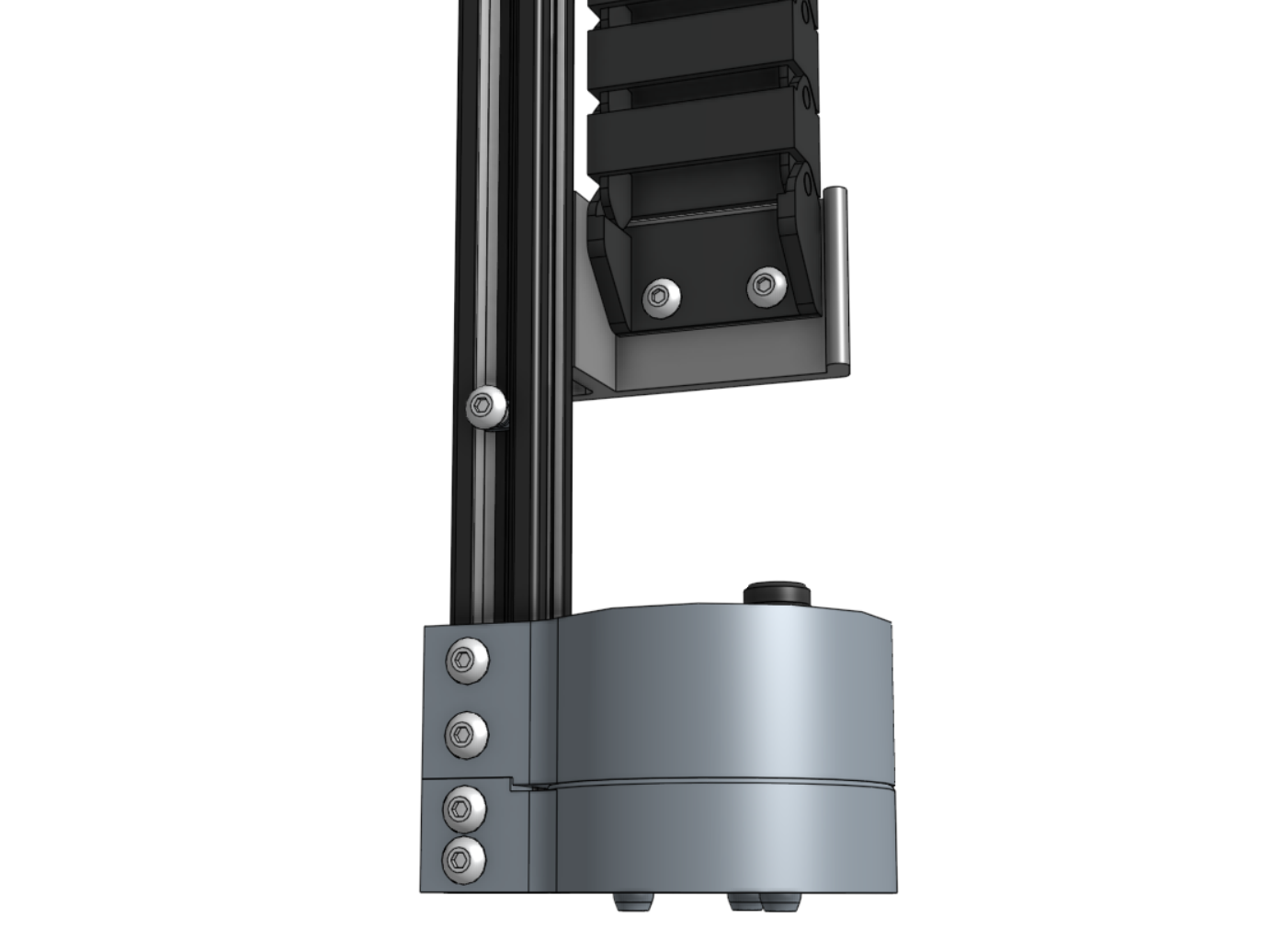

Step 7: Mount the cable carrier to the z-axis

Attach the cable carrier to the lowest vertical cable carrier support using two M5 x 16mm screws, M5 washers, M5 locknuts. The screws should thread firmly through the cable carrier end pieces. The mount should be about 100mm or more away from the UTM, but the location can be adjusted as necessary to aid cable installation.

Step 7: Feed the z-axis motor and encoder cables

Feed the z-axis motor and encoder cables up through the slots in the vertical cable carrier supports, and then through the slot in the z-axis motor mount.

Connect the cables to the z-axis motor and encoder.

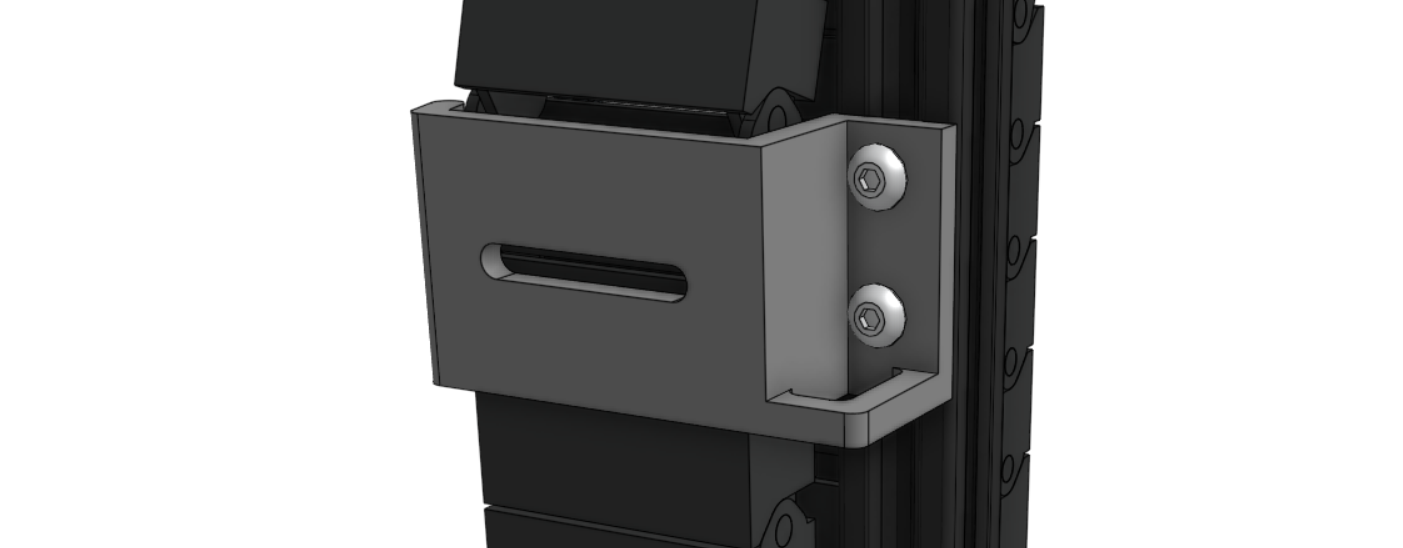

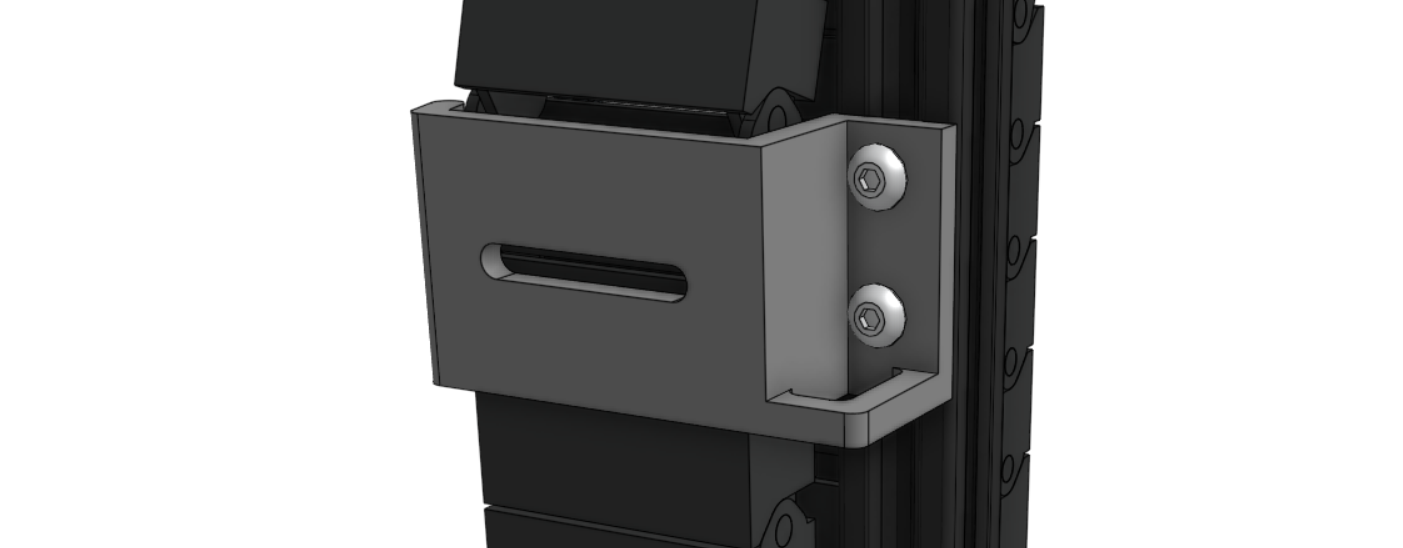

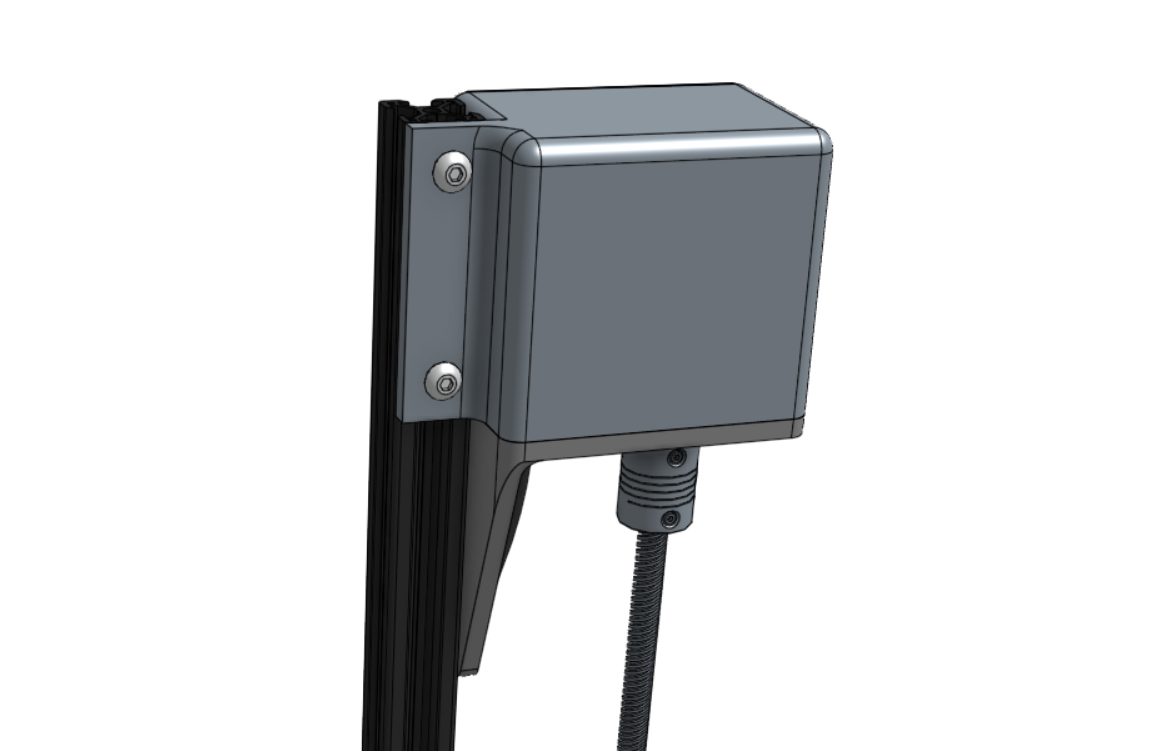

Step 8: Add the vertical motor housing

Attach the vertical motor housing to the z-axis extrusion using two M5 x 10mm screws and M5 tee nuts.

Step 9: Snap in the remaining tabs

Once everything is situated well, snap-in the remaining cable carrier tabs, ensuring that you maintain organization of the cables and tubing.

Not easy to adjust

Once you snap-in the remaining tabs, it will become impossible to adjust any of the cables and tubing without removing the majority of the tabs first. Make sure everything is in place before you make a bunch of extra work for yourself.