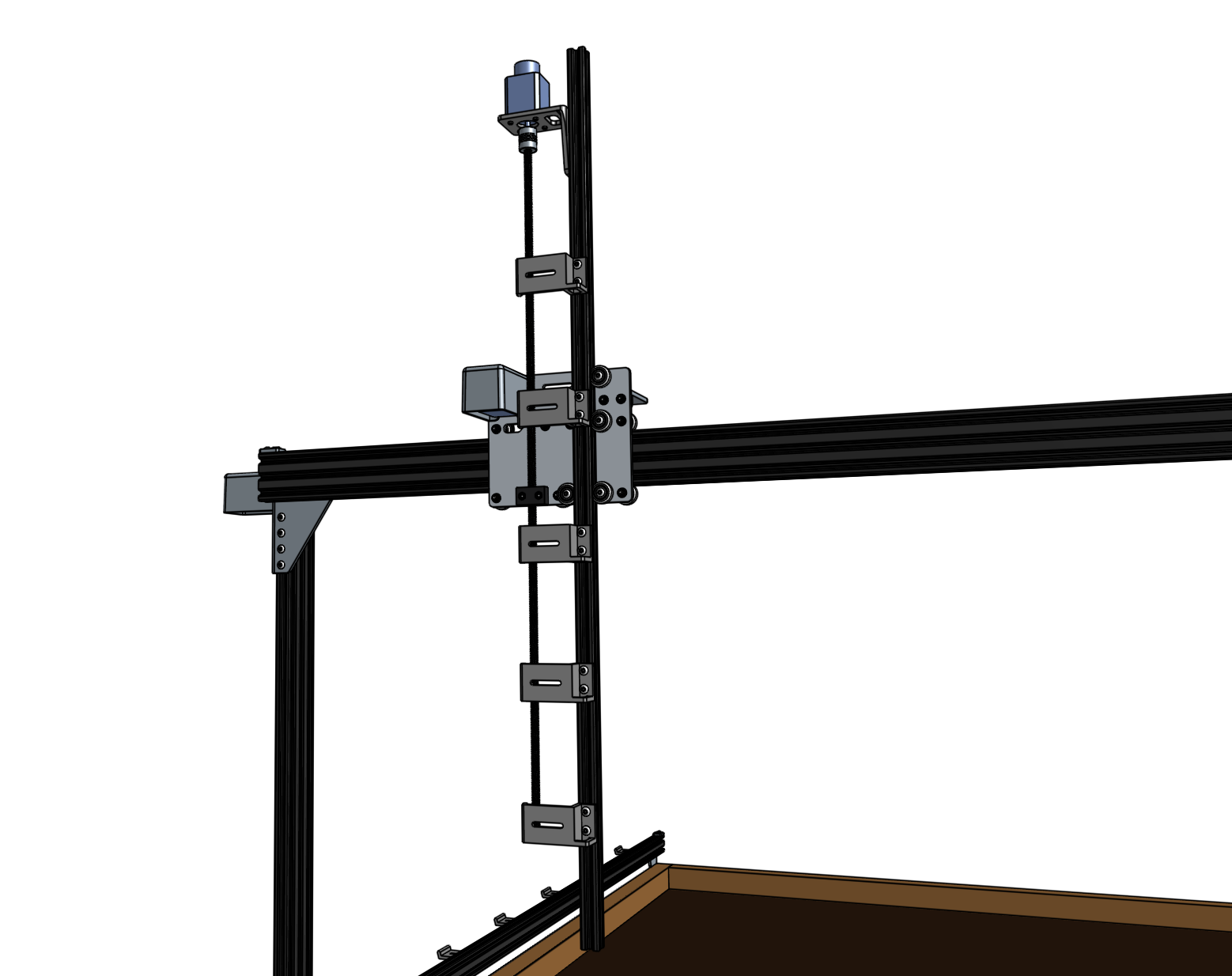

Install the Z-Axis

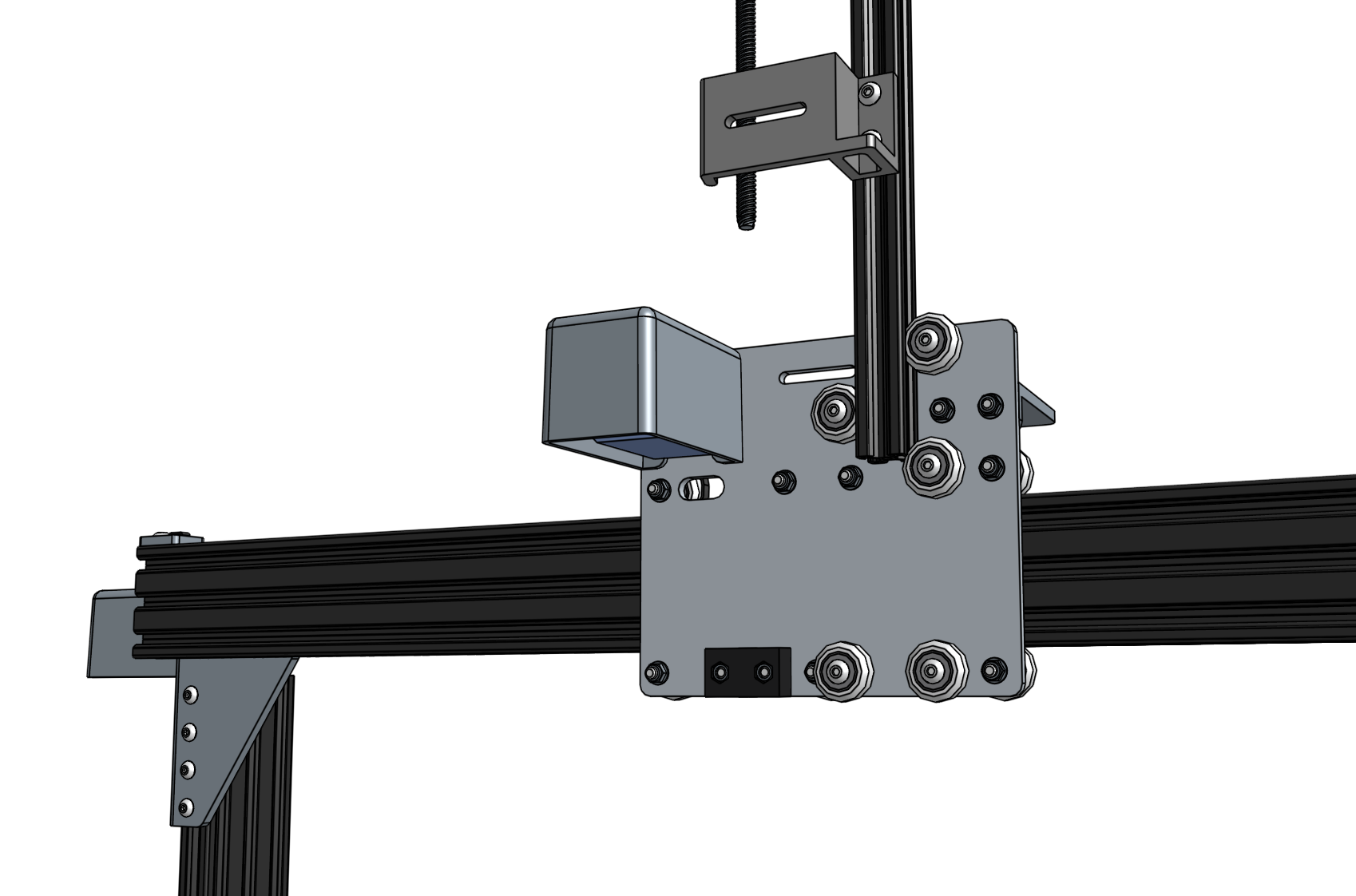

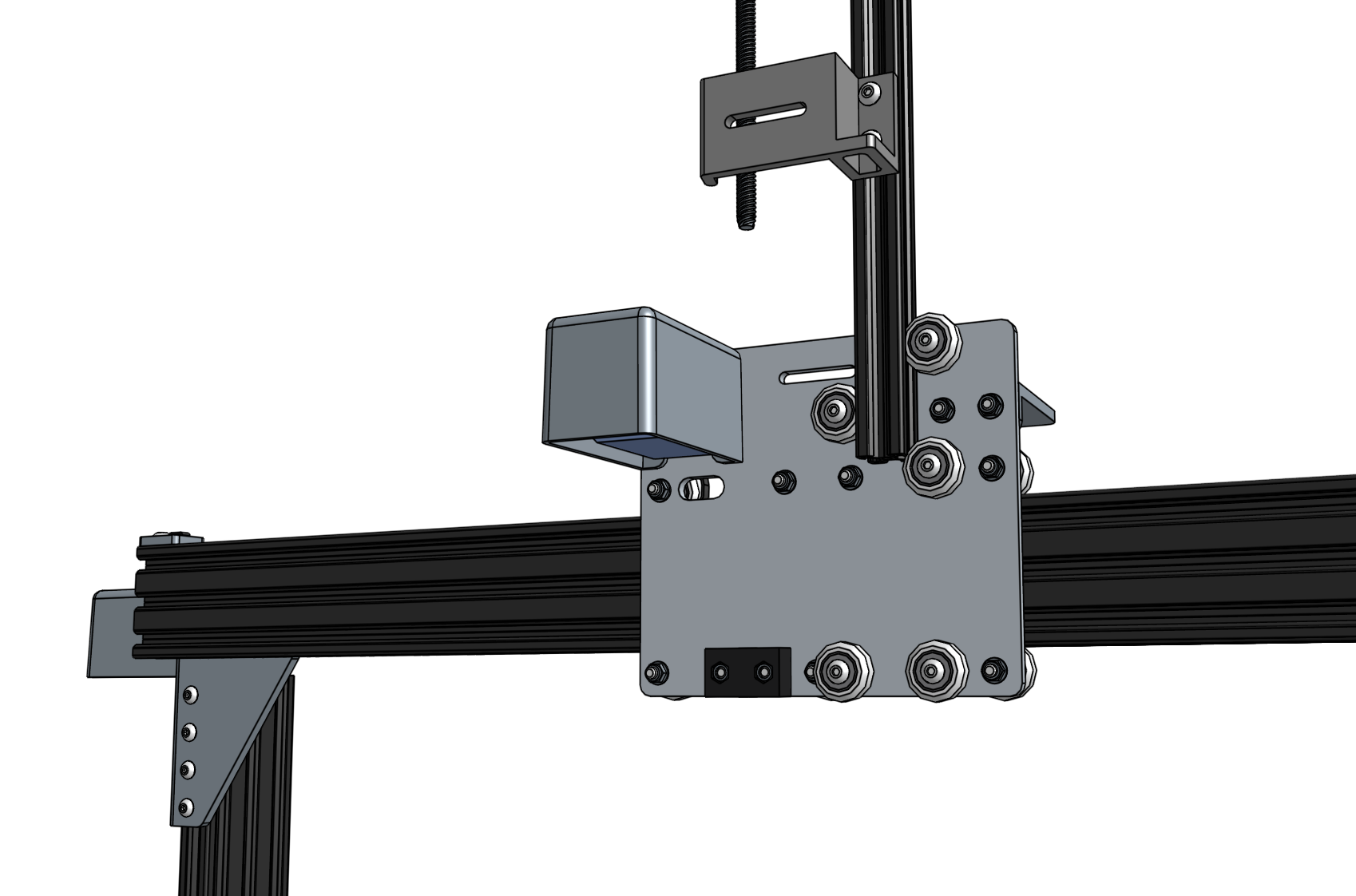

Step 1: Attach the z-axis to the cross-slide

Slide the z-axis extrusion through the v-wheels on the cross-slide until the leadscrew is resting on the leadscrew block.

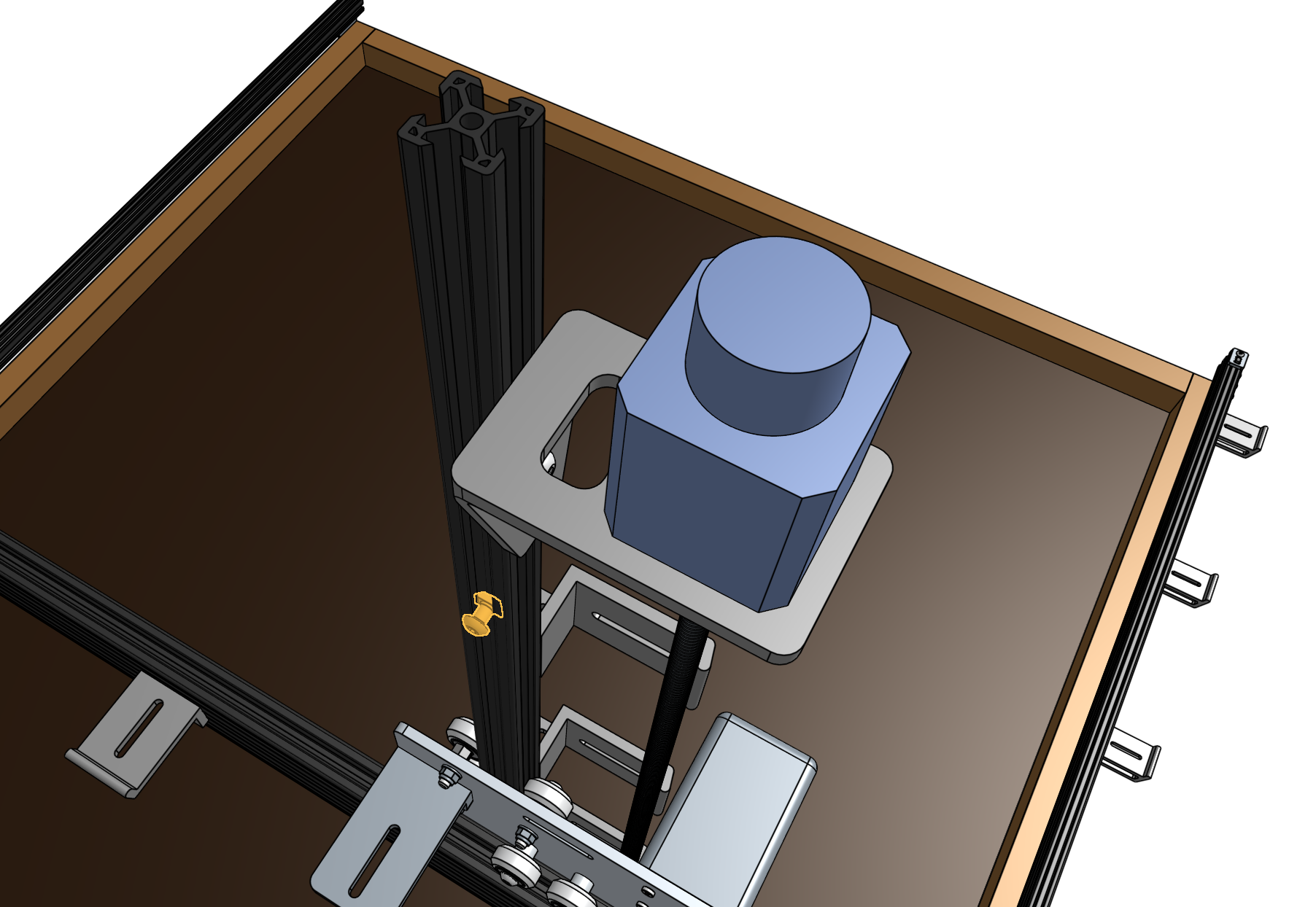

Adjust the eccentric spacers as needed

In order to slide the z-axis through the v-wheels you will need to adjust the eccentric spacers of the three v-wheels on the right side of the cross-slide. Refer to the eccentric spacer adjustment reference guide for how to do this.

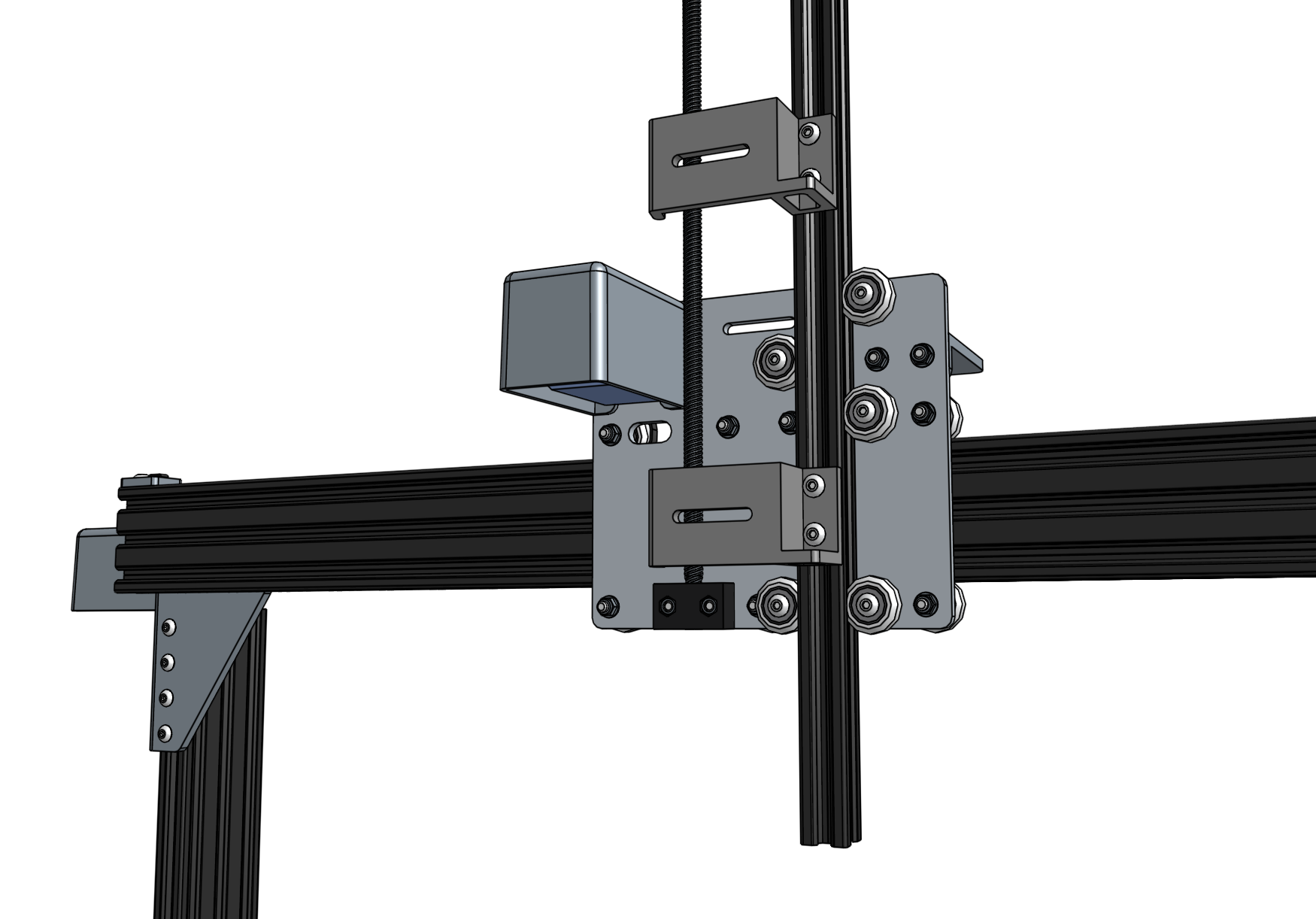

Step 2: Screw the screw

Hand rotate the leadscrew clockwise so that it threads into the leadscrew block. Continue to hand rotate the leadscrew until the z-axis is halfway down.

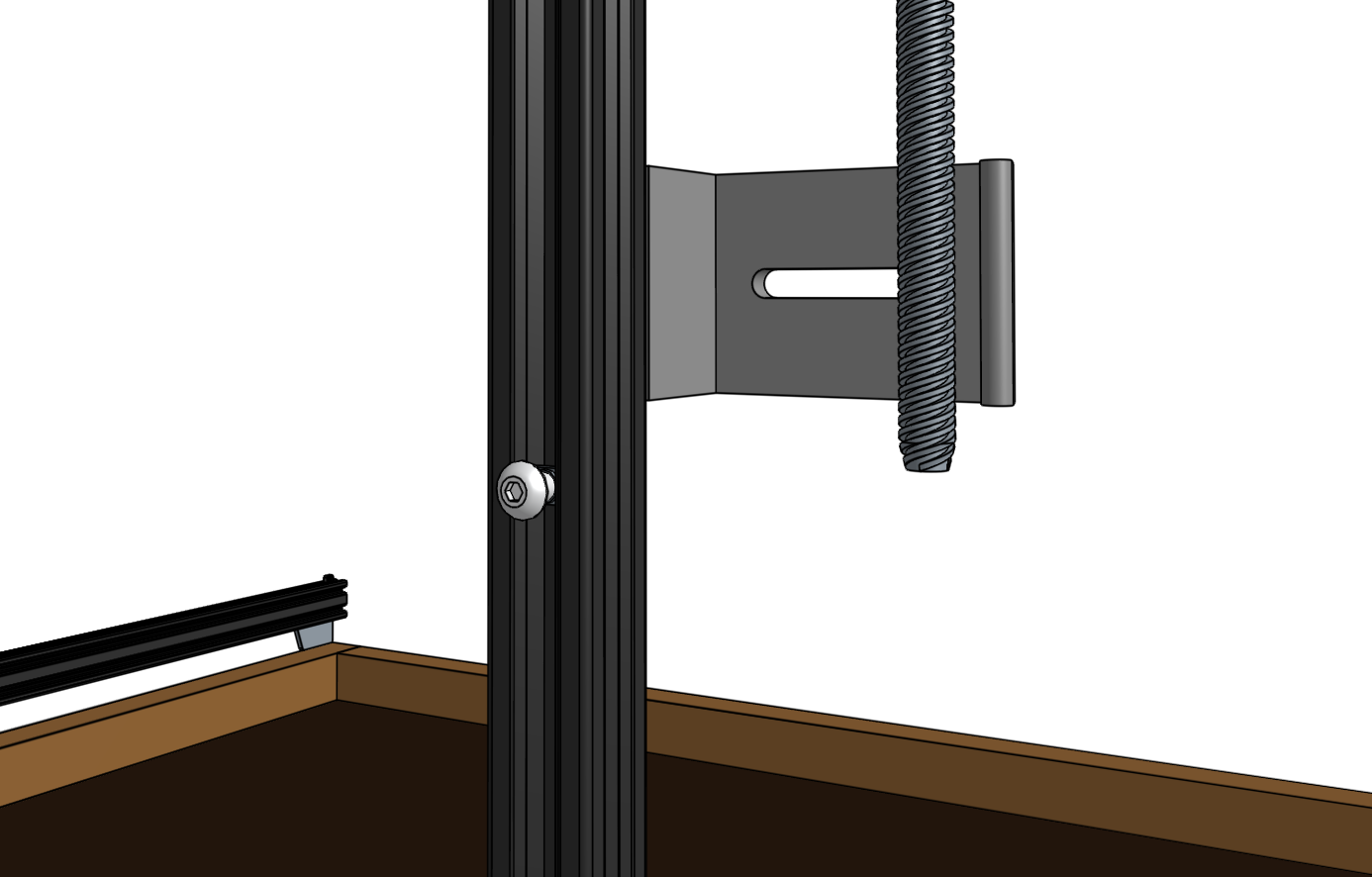

Step 3: Install the hard stops

Tighten an M5 x 10mm screw and tee nut onto the backside of the z-axis extrusion approximately 200mm from the top of the extrusion. This acts as a hard stop between the z-axis and the cross-slide plate, which you can quickly adjust to physically prevent FarmBot from ever moving too low within its working space, which could damage something.

The hard stop is highlighted orange for clarity.

Tighten another M5 x 10mm screw and tee nut onto the backside of the z-axis extrusion approximately 100mm from the bottom of the extrusion. This hard stop prevents the z-axis from moving too high.