High Level Overview

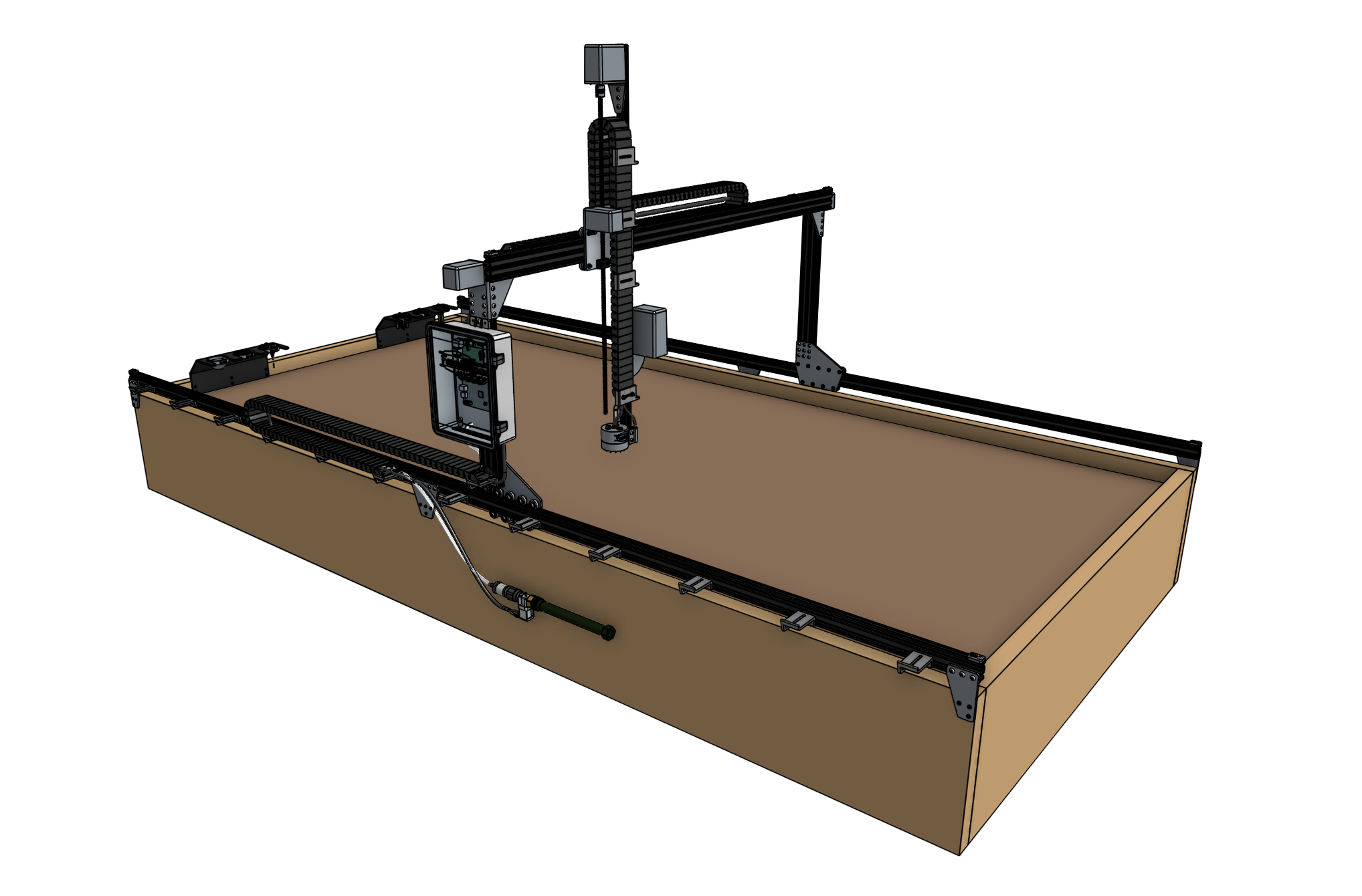

Bird’s eye view of FarmBot Genesis

FarmBot Genesis is a small scale FarmBot primarily constructed from V-Slot aluminum extrusions and aluminum plates and brackets. Genesis is driven by four NEMA 17 stepper motors with rotary encoders, the Farmduino microcontroller, and a Raspberry Pi 3 computer. Genesis can vary in size from a planting area as little as 1m2 to a maximum of 4.5m2, while accommodating a maximum plant height of about 1m. With additional hardware and modifications we anticipate the Genesis concept could scale to approximately 50m2 and a maximum plant height of 1.5m.

Not your typical product

We’ve gone through great lengths to design FarmBot Genesis to be durable, easily assembled and modified with common tools, constructed from largely off-the-shelf components, and manufactured with readily available processes and materials. Nothing about FarmBot speaks obsolescence or proprietary.

We’ve done this because at our core, we’re makers and hackers just like you. We enjoy tearing apart our gadgets and gizmos to fix them, improve them, and make them different and unique. So that’s what FarmBot Genesis is all about - empowering you to truly own FarmBot technology inside and out.

Go ahead and make your tracks longer, design a tool that electrocutes weeds, program FarmBot to spray water at the local cats, grow mushrooms, flowers, hydroponically, or on your living room wall! We can’t wait to see what you do with FarmBot.

We hope you’ll find our documentation useful and a great starting point for working with FarmBot and making it your own. If you ever have any questions, please head on over to the forum. Cheers! 🍻

Tracks

Tracks are one of the components that really differentiate FarmBot technology from traditional free-driving wheeled tractors. The tracks are what allow the system to have great precision in an efficient and simple manner. There are many reasons of why tracks are superior, a few of which are listed below.

- Tracks provide great precision and allow the the FarmBot to return to the same position repeatedly

- Any type of packing structure of plants can be created and managed

- Tracks take up less area than paths for tractor wheels and do not compact the soil

Gantry

The Gantry is the the structural component that bridges the two Tracks and moves in the X-direction via an X-Direction Drive System. Typically, it serves as a linear guide for the Cross-Slide and a base for the Y-Direction Drive System that moves the Cross-Slide across the Gantry in the Y-direction. It can also serve as a base for mounting other tools, electronics, supplies, and/or sensors.

Cross-slide

The Cross-Slide moves in the Y-Direction across the Gantry. This motion provides the second major degree of freedom for FarmBots and allows operations such as planting to be done anywhere in the XY plane. The Cross-Slide is moved using a Y-Direction Drive System and functions as the base for the Tool Mount and Z-Direction Drive System.

Z-axis

The Z-axis attaches to the Cross-Slide and provides the FarmBot with Z-Direction movement. It serves as the base for attaching the Universal Tool Mount and other Tools.

Raised tracks vs low tracks

For FarmBots to properly grow taller plants, the Gantry, Cross-Slide, Z-Axis, and Tools must have adequate vertical clearance from the plants. This can generally be accomplished in two ways:

- Using raised tracks and a low-profile gantry

- Using low tracks with a tall gantry

In general, using low tracks with a tall gantry is the better design, especially for larger applications because it saves on material cost, is less of an eyesore, blocks less sunlight, and would be easier to maintain. However, in the case of a FarmBot being installed in a greenhouse or other structure, utilizing the existing walls to support the tracks higher may be a better solution.