Assemble the Tracks

Step-by-step instructions for assembling FarmBot’s tracks

- Step 1: Gather the parts and tools

- Step 2: Lay out the track extrusions

- Step 3: Attach a track end plate

- Step 4: Attach a track joining plate

- Step 5: Attach the first track extrusion

- Step 6: Attach the second track end plate and extrusion

- Step 7: Install the other track

- Step 8: Add the horizontal cable carrier supports

- What’s next?

2 hours

This is the estimated time it will take to assemble the tracks.

Supporting Infrastructure Required

These assembly instructions assume that you already have supporting infrastructure in place, such as a raised bed.

Step 1: Gather the parts and tools

Gather all the parts from the table below and lay them out in a logical manner. To complete the assembly, you will also need the following tools:

- 3mm hex driver

- Phillips screwdriver (or drill with phillips bit)

| Qty. | Component |

|---|---|

| 4 | Track Extrusions (20 x 40 x 1500mm) |

| 4 | Track End Plates |

| 2 | Track Joining Plates |

| 20 | 25mm Wood Screws |

| 42 | M5 x 10mm Screws |

| 42 | M5 Tee Nuts |

| 11 | Horizontal Cable Carrier Supports |

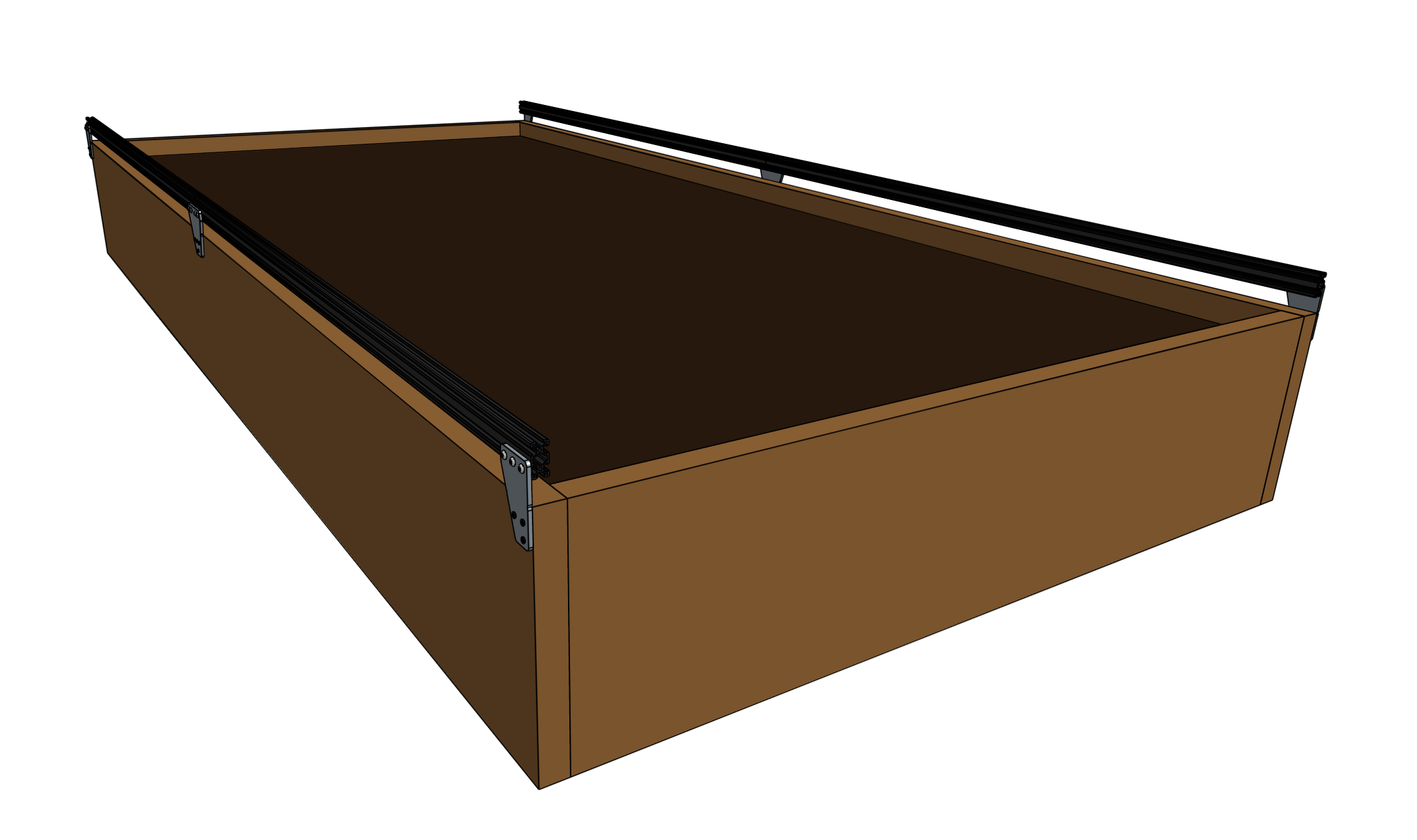

Step 2: Lay out the track extrusions

Lay out all of the track extrusions in the location that you want to attach them to your supporting infrastructure. Make sure that extrusions are fully butted against each other. This will help you attach the plates in the correct location.

Overhang is a-ok

The ends of your tracks do not have to match up perfectly with the ends of your supporting infrastructure. A little overhang or coming up short is just fine.

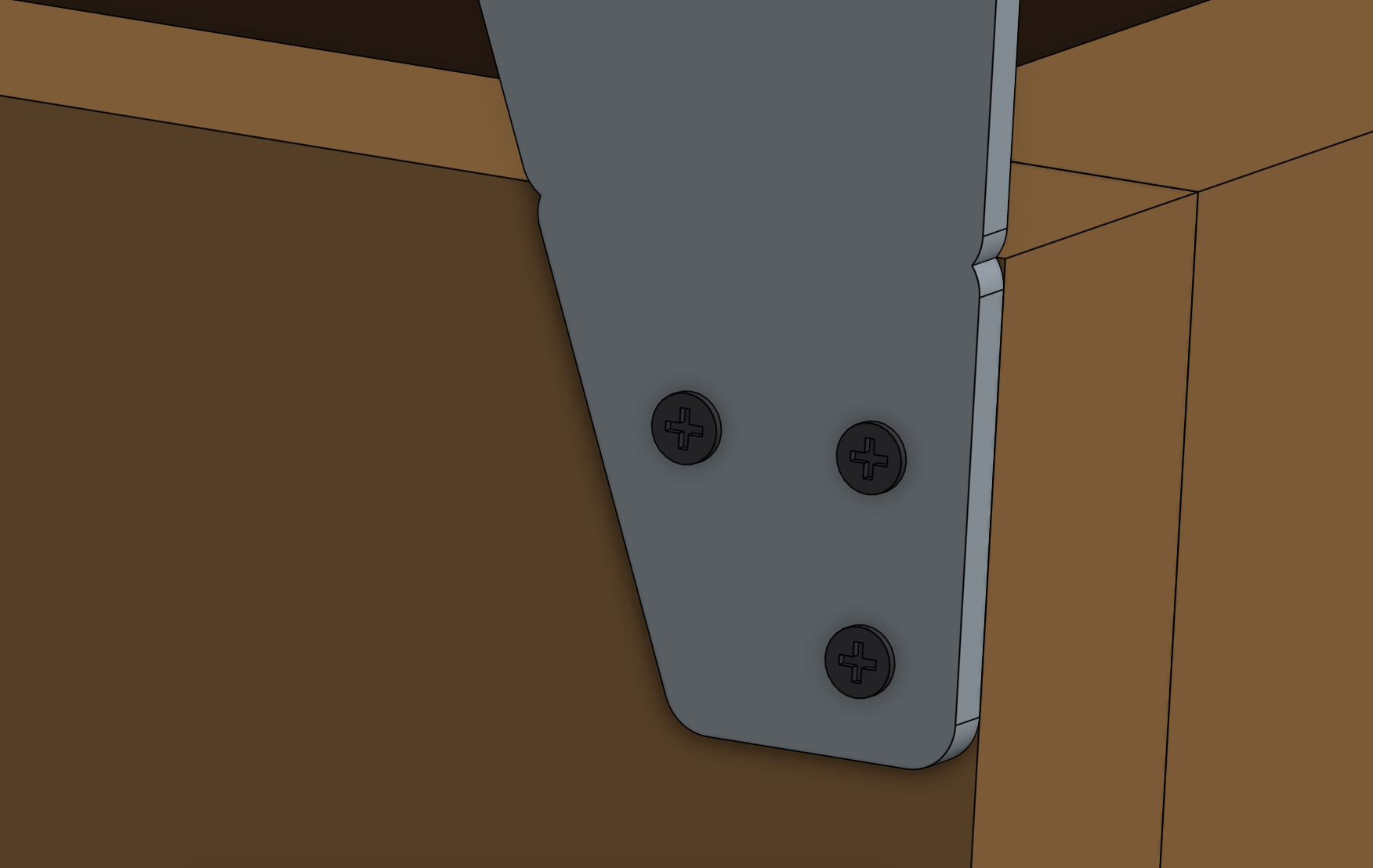

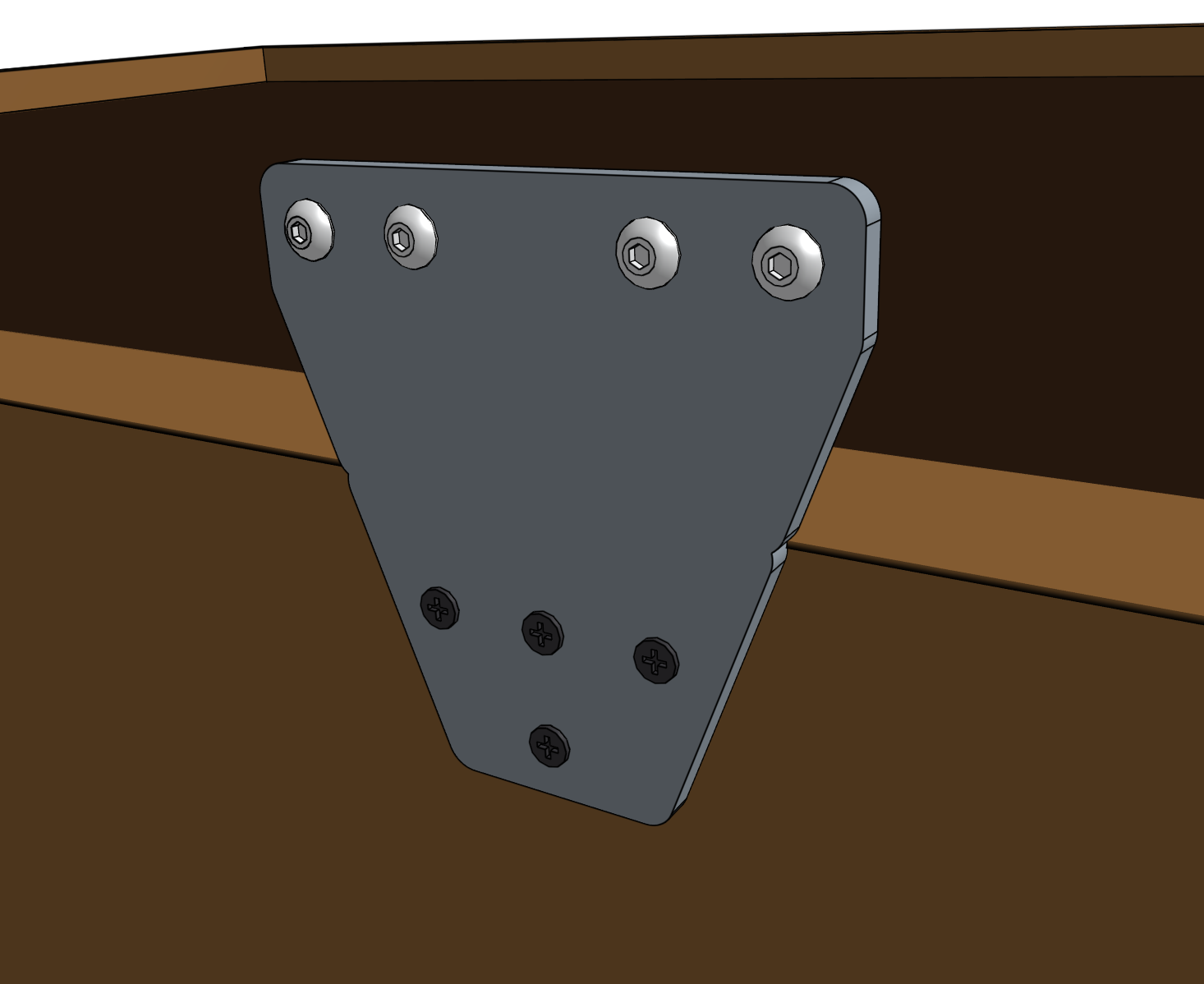

Step 3: Attach a track end plate

Position a track end plate as shown below and screw it into the supporting infrastructure with three wood screws.

Vertically aligned

All of the track extrusions must be the same height and aligned along their length so that the gantry can move across the tracks smoothly. This means that all of the track end plates and track joining plates need to be vertically aligned.

We’ve added small notches into the track end plates and track joining plates so that you can position the plates with perfect vertical alignment with respect to your supporting infrastructure and each other. You should only use these notches if the top edge of your supporting infrastructure is level and straight.

If the top edge of your supporting infrastructure is not level or straight, then you will need to manually ensure that your track plates are vertically aligned with other means. Because the gantry has wheels that ride on the bottom face of the track extrusions, you need to ensure that the bottom of the track extrusion will be at least 25mm away from the top of the supporting infrastructure so that the wheels have adequate clearance.

Lightly screw three M5 x 10mm screws and tee nuts to the track end plate.

Orient the tee nuts horizontally.

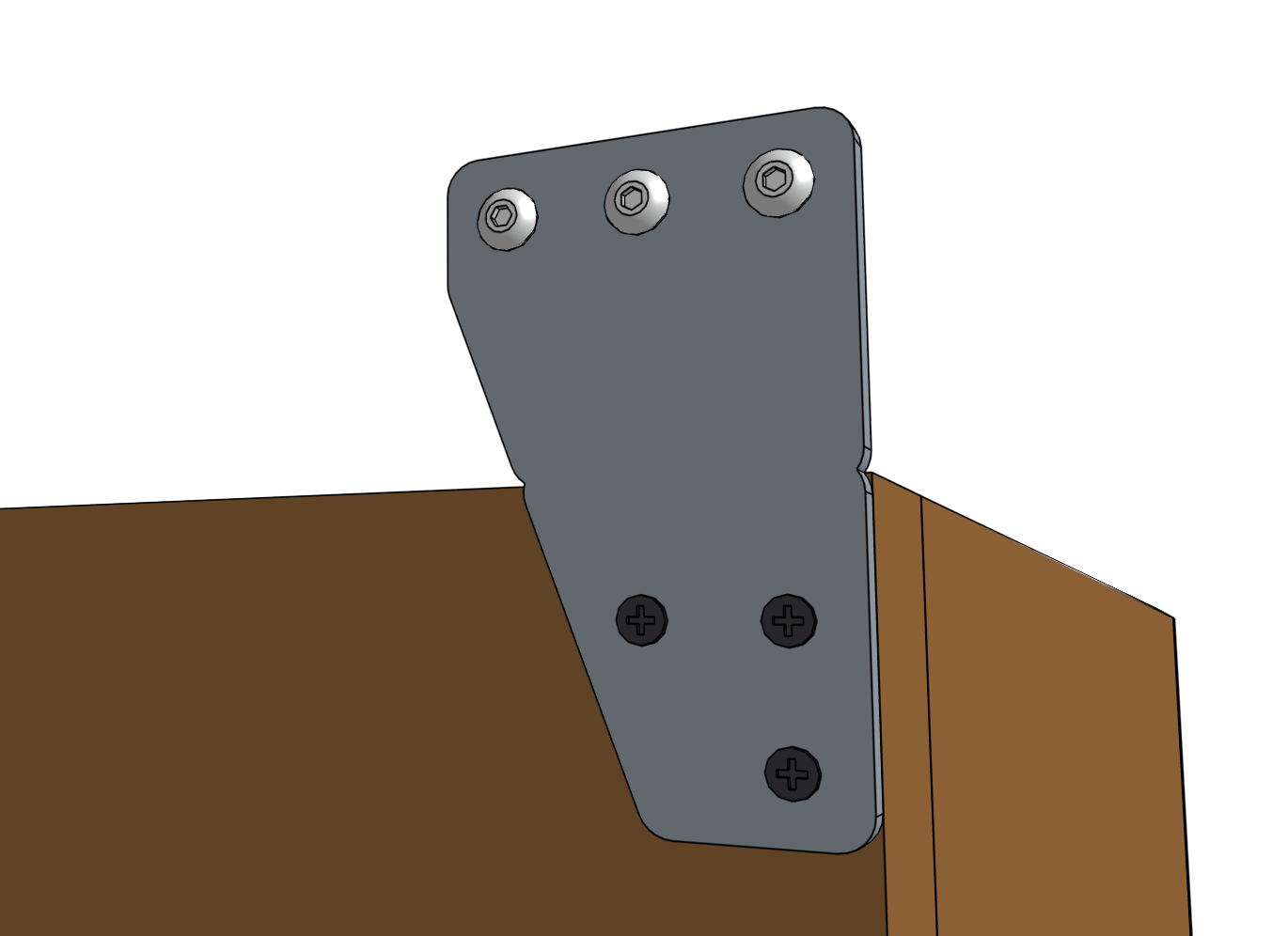

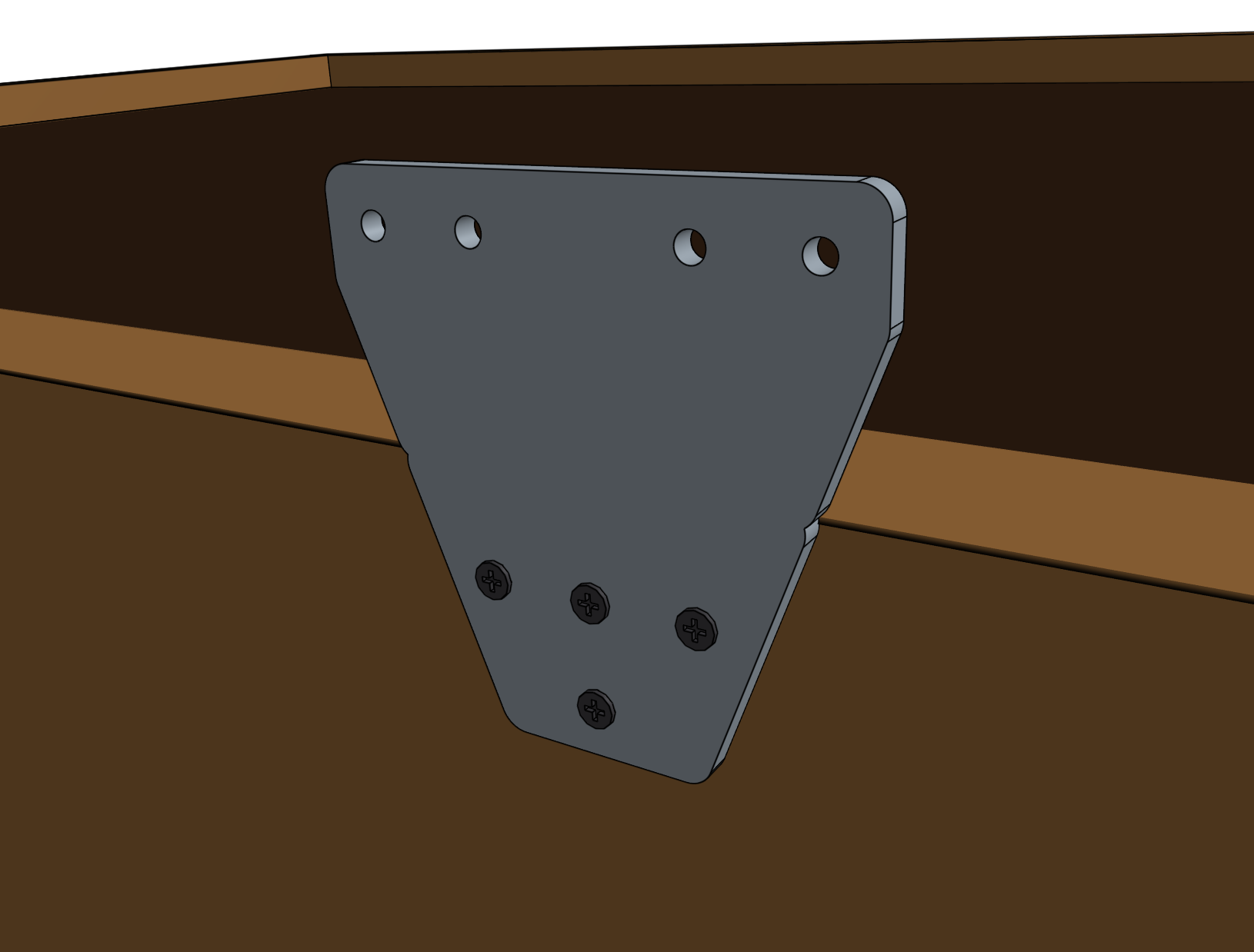

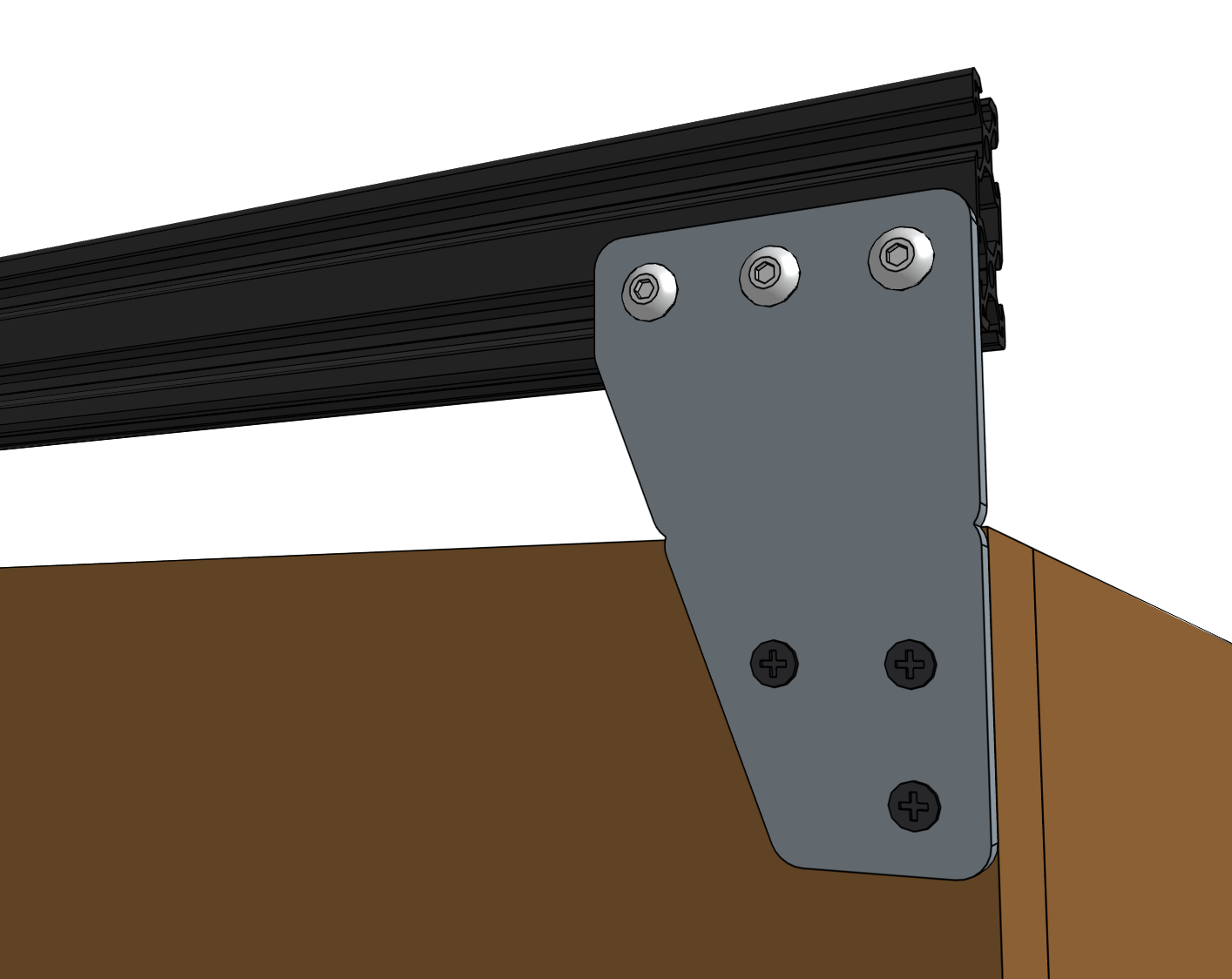

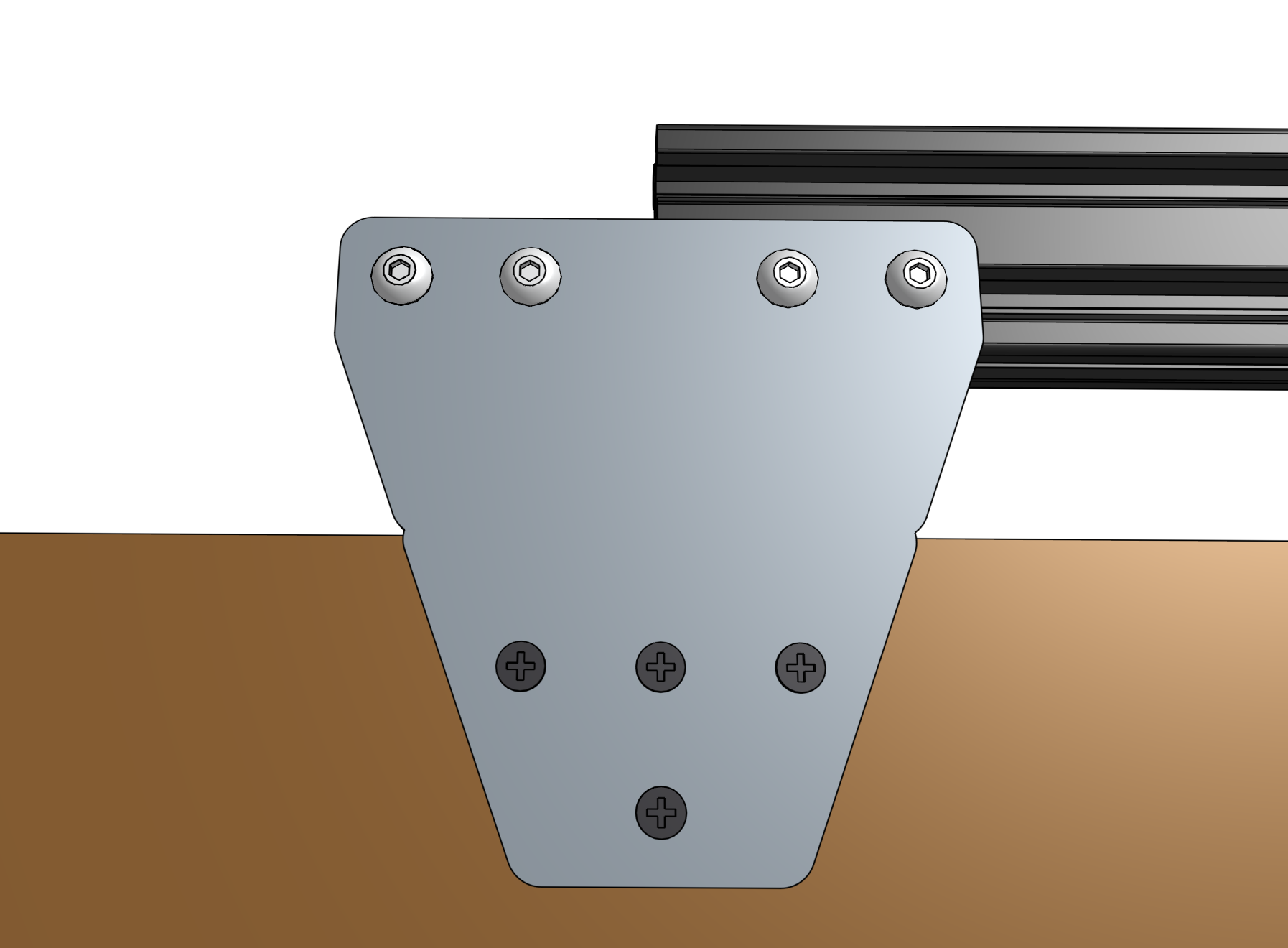

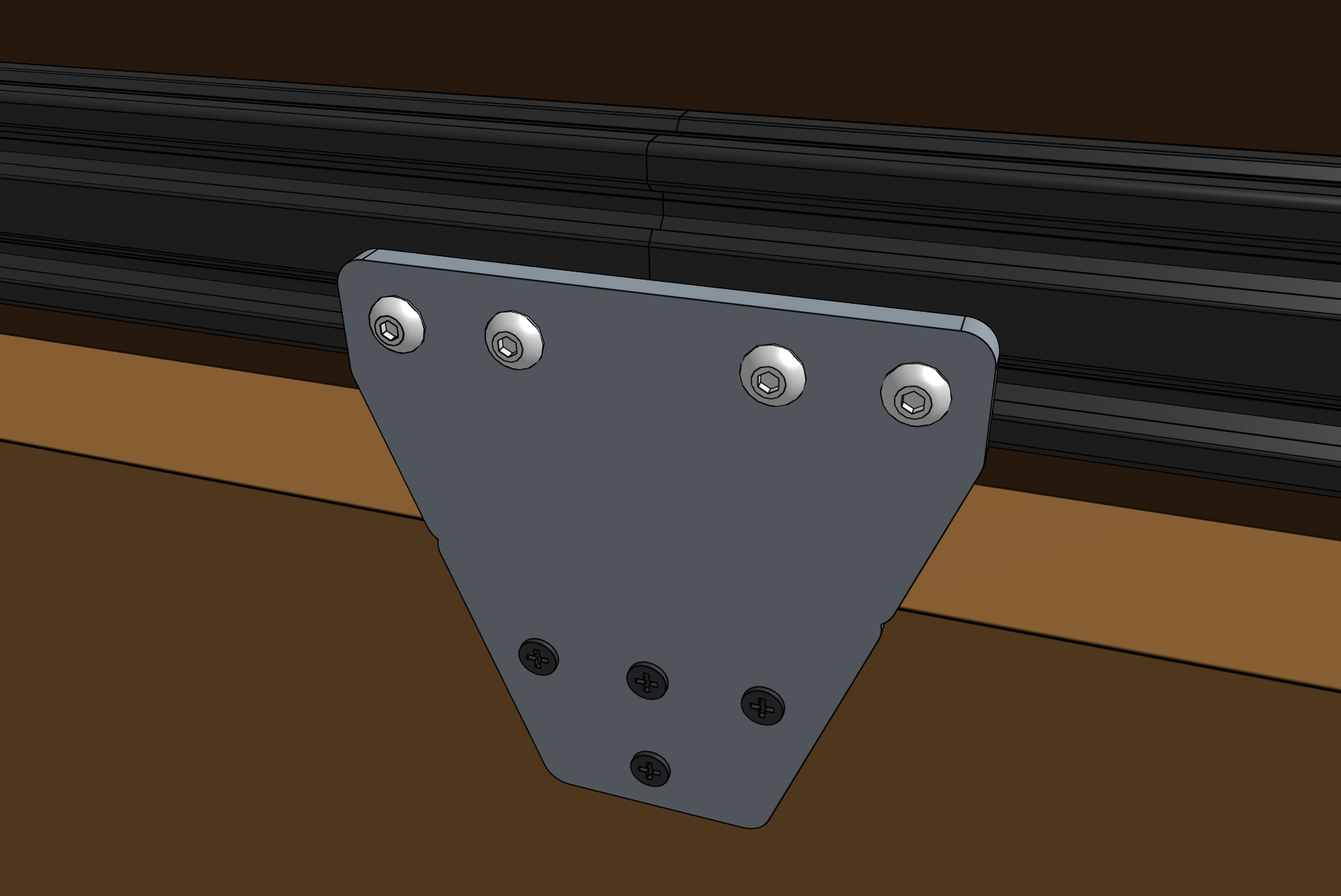

Step 4: Attach a track joining plate

Position a track joining plate such that one half of it will be able to attach to each track extrusion and so that it is vertically aligned with the first track end plate. Screw the plate into the supporting infrastructure with four wood screws.

Lightly screw four M5 x 10mm screws and tee nuts to the track joining plate. Orient the tee nuts horizontally.

Step 5: Attach the first track extrusion

Lift the track extrusion and position the lower V-slot onto the tee nuts of the track end plate. Lightly tighten one of the M5 x 10mm screws using the 3mm hex driver to prevent the extrusion from falling off, while still allowing it to move loosely.

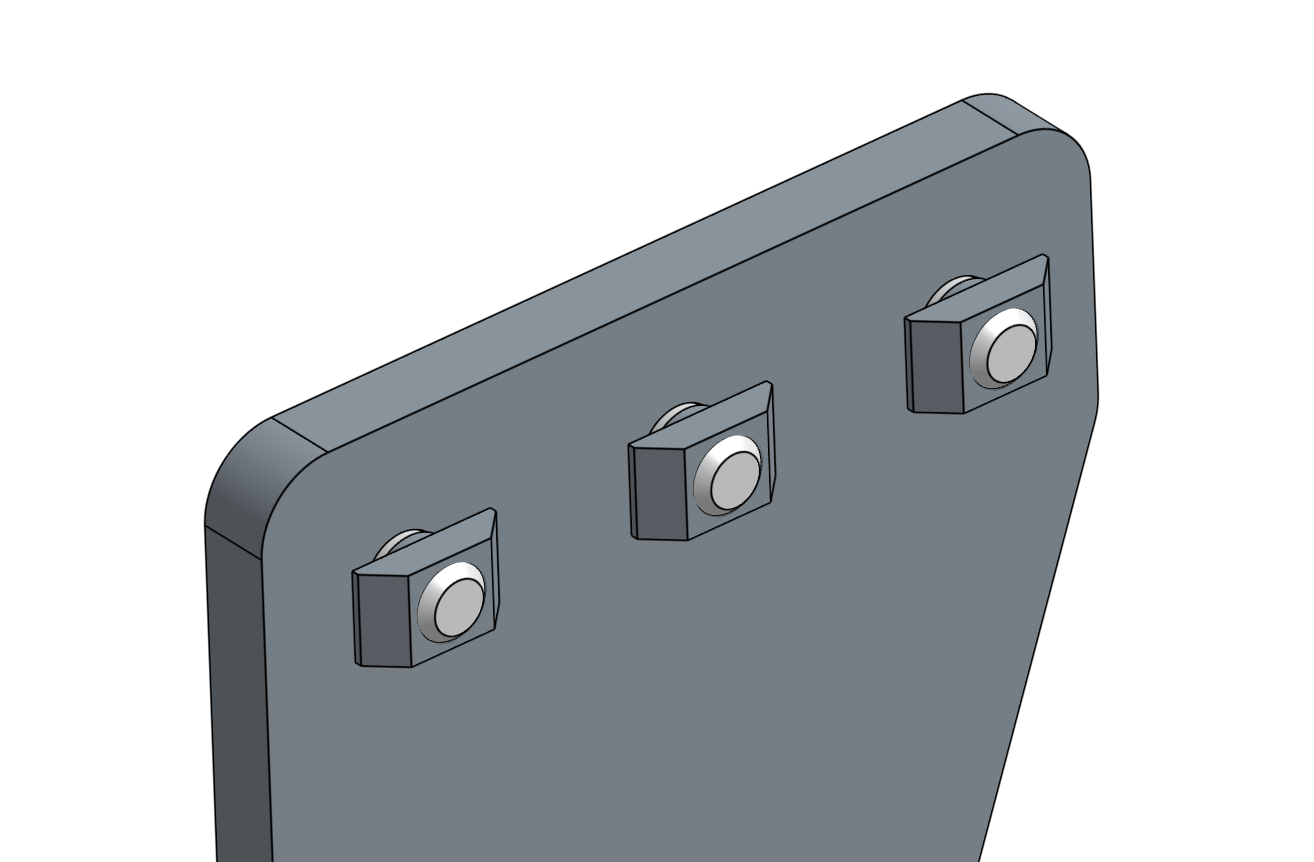

Ensure the tee nuts are rotating

In order for the tee nuts to fasten the extrusion to the plate, the tee nuts must rotate 90 degrees when you begin tightening the screw so that the tee nut’s flanges can grip the inside faces of the extrusion slot. You can see how this works by looking in the end of the extrusion slot when you tighten a screw and tee nut. If the nut doesn’t grip the slot the first time, simply loosen the screw and try again.

Note: The tee nuts are designed to only rotate 90 degrees, so in most cases you can simply begin tightening the screw and the tee nut will orient itself correctly without any intervention.

This image shows a tee nut that has correctly rotated 90 degree and is gripping the inside faces of the extrusion slot.

Lift the other end of the track extrusion and position the lower V-slot onto two of the tee nuts in the track joining plate. Verify that the track extrusion is positioned correctly, and then fully tighten all five of the M5 x 10mm screws that fasten the extrusion to the two plates.

Step 6: Attach the second track end plate and extrusion

Follow the instructions in Steps 3 and 5 to attach the second track end plate and second track extrusion.

Extrusion alignment is key

Position your track extrusions tightly together at the middle of the track joining plate. The top and bottom of the extrusions must be flush so that the gantry can move across the tracks smoothly. Ensure that your extrusions are parallel (no kink where they meet) by looking down the length of the tracks. If there is a kink, adjust the track extrusions and plates accordingly.

Perfectly aligned track extrusions are key to smooth gantry movements!

Step 7: Install the other track

Repeat steps 3 through 6 for the track on the other side of the bed.

Parellel or bust

It is critical that the distance between the two tracks is consistent. If it is not, there will be harmful forces placed on the gantry and tracks as the gantry moves across the non-parallel tracks.

You can use shims or other spacers to better align track plates in case your supporting infrastructure is not perfect.

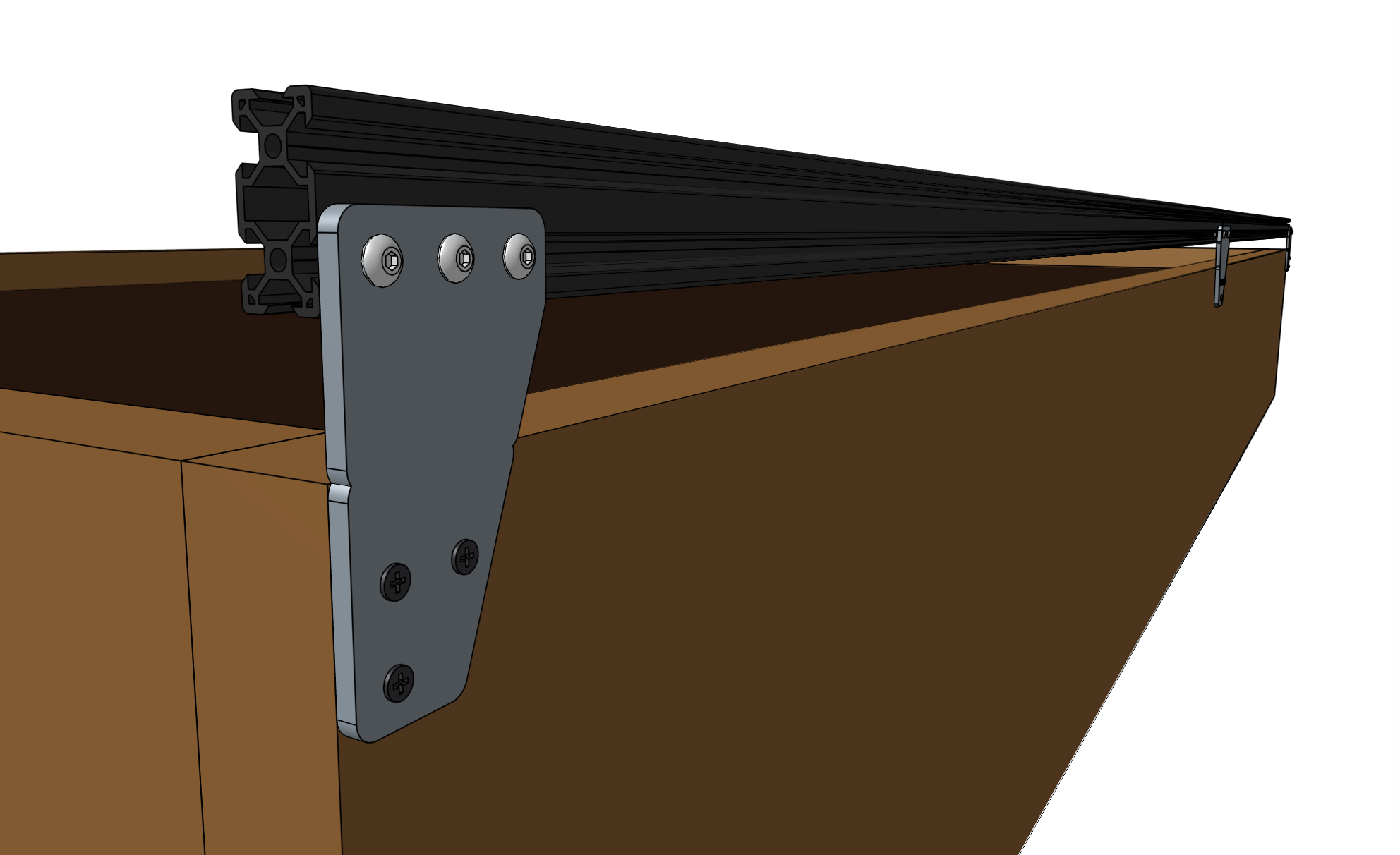

Step 8: Add the horizontal cable carrier supports

Insert two M5 x 10mm screws into a horizontal cable carrier support and lightly screw on two M5 tee nuts. Place the assembly into the lower slot of the left side track, near the end of the track. Use the 3mm driver to tighten the screws.

Add 10 more horizontal cable carrier supports evenly along the left side track so that there are 11 total installed. There should be five to six supports per track extrusion.

Woo hoo!

You’ve just finished installing your FarmBot’s tracks - arguably one of the most difficult parts of setting up your device.

Onward!