Y-Axis Cable Carrier

- Step 1: Prepare the cable carrier

- Step 2: Orient the cable carrier

- Step 3: Add the y-axis motor and encoder cables

- Step 4: Connect the tubing

- Step 5: Connect the cabling

- Step 6: Lay everything into the cable carrier

- Step 7: Snap in some tabs

- Step 8: Mount the cable carrier

- Step 9: Snap in the remaining tabs

- Step 10: Connect the y-axis motor and encoder

- What’s next?

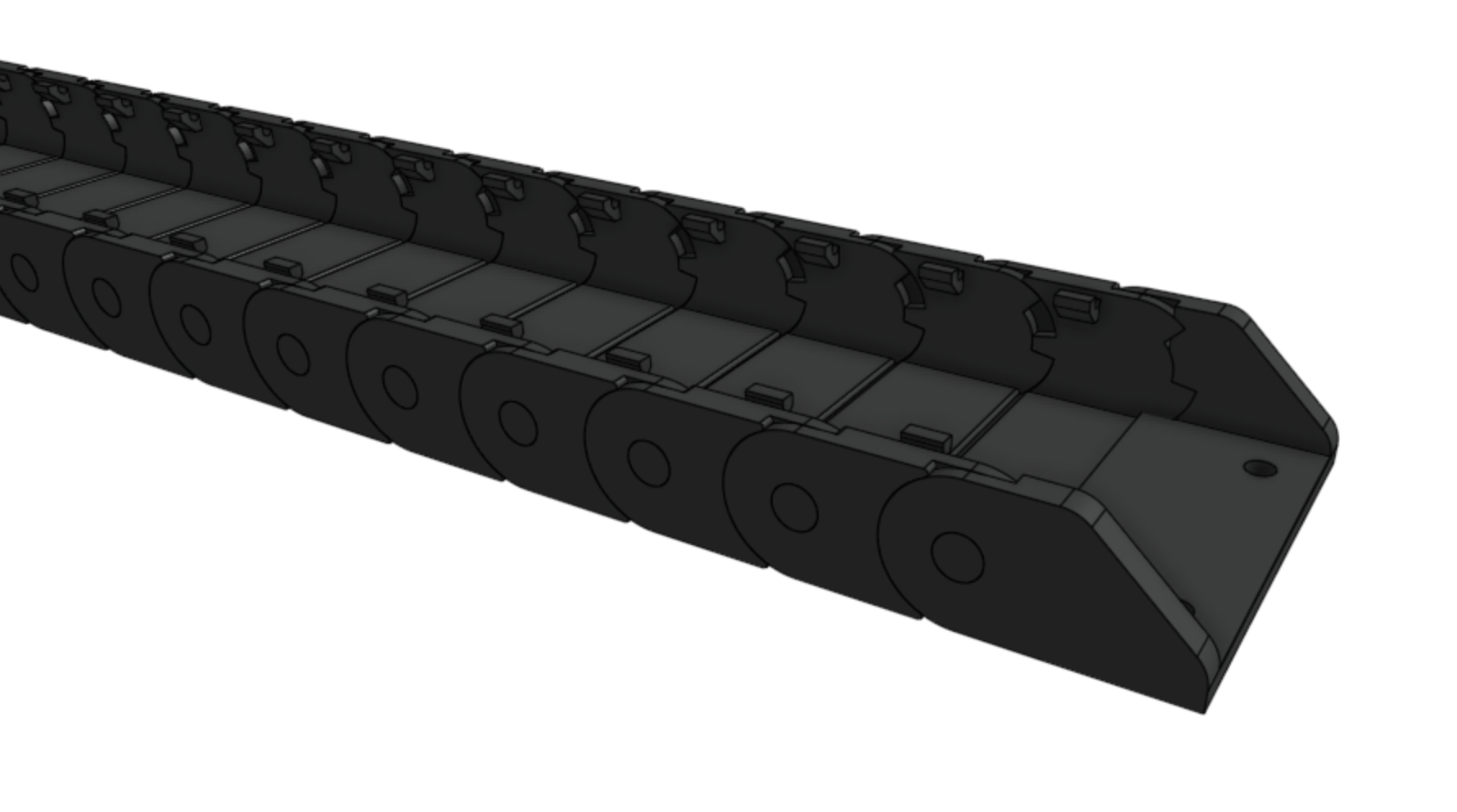

Step 1: Prepare the cable carrier

Remove all of the snap-in tabs from the y-axis cable carrier. Note that the x-axis and y-axis cable carriers are the same length, but the y-axis cable carrier is wider than the x-axis one.

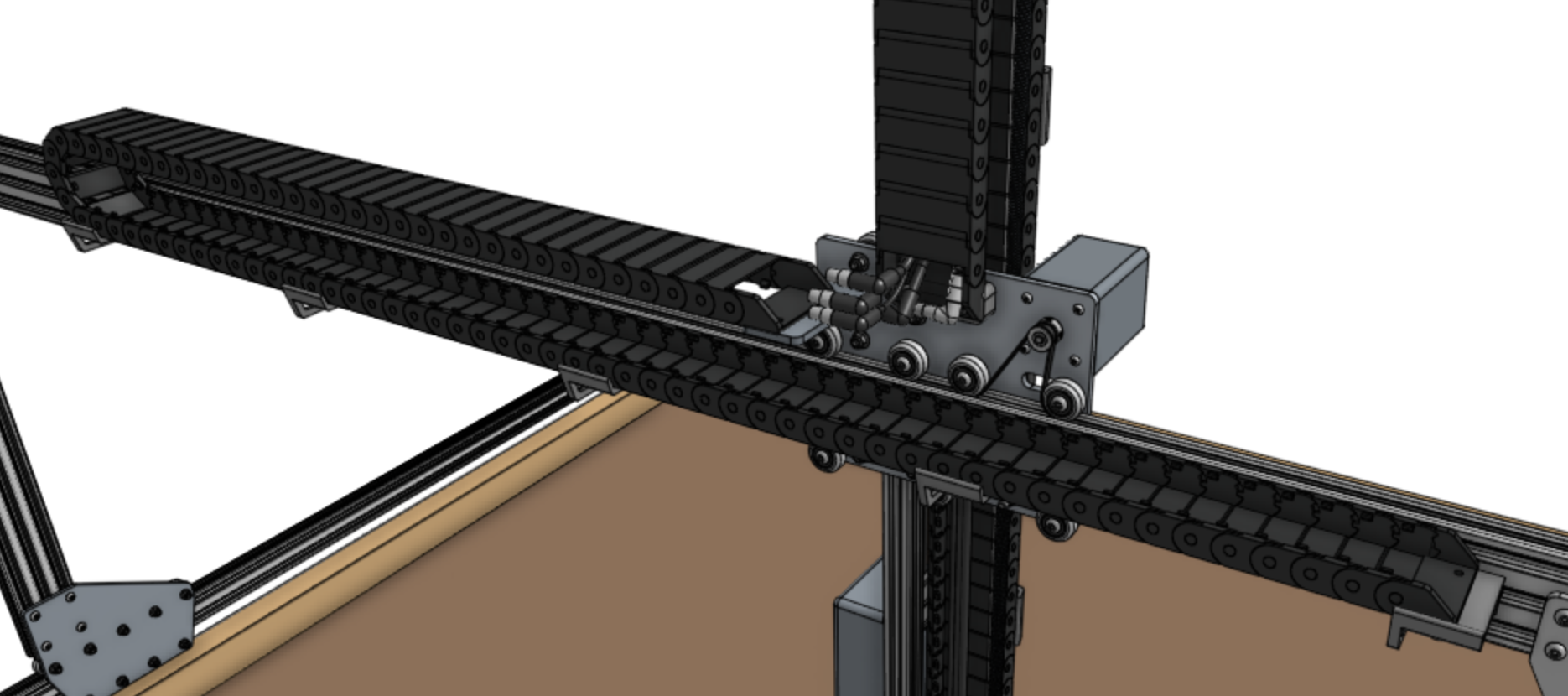

Step 2: Orient the cable carrier

There is only one orientation that the y-axis cable carrier mounts to the cross-slide and gantry, and it is determined by the orientation of the end pieces. Lay the cable carrier onto the gantry’s horizontal cable carrier supports but do not attach it at this time.

Step 3: Add the y-axis motor and encoder cables

Feed the y-axis motor and encoder cables through the slot in the cross-slide plate such that there is enough cable length so that they can be comfortably connected to the motor and encoder. Ensure you feed the correct end of the cables through the slot by checking the connection with the y-axis motor and encoder. However, do not keep them plugged in at this time as they can be damaged if pulled on.

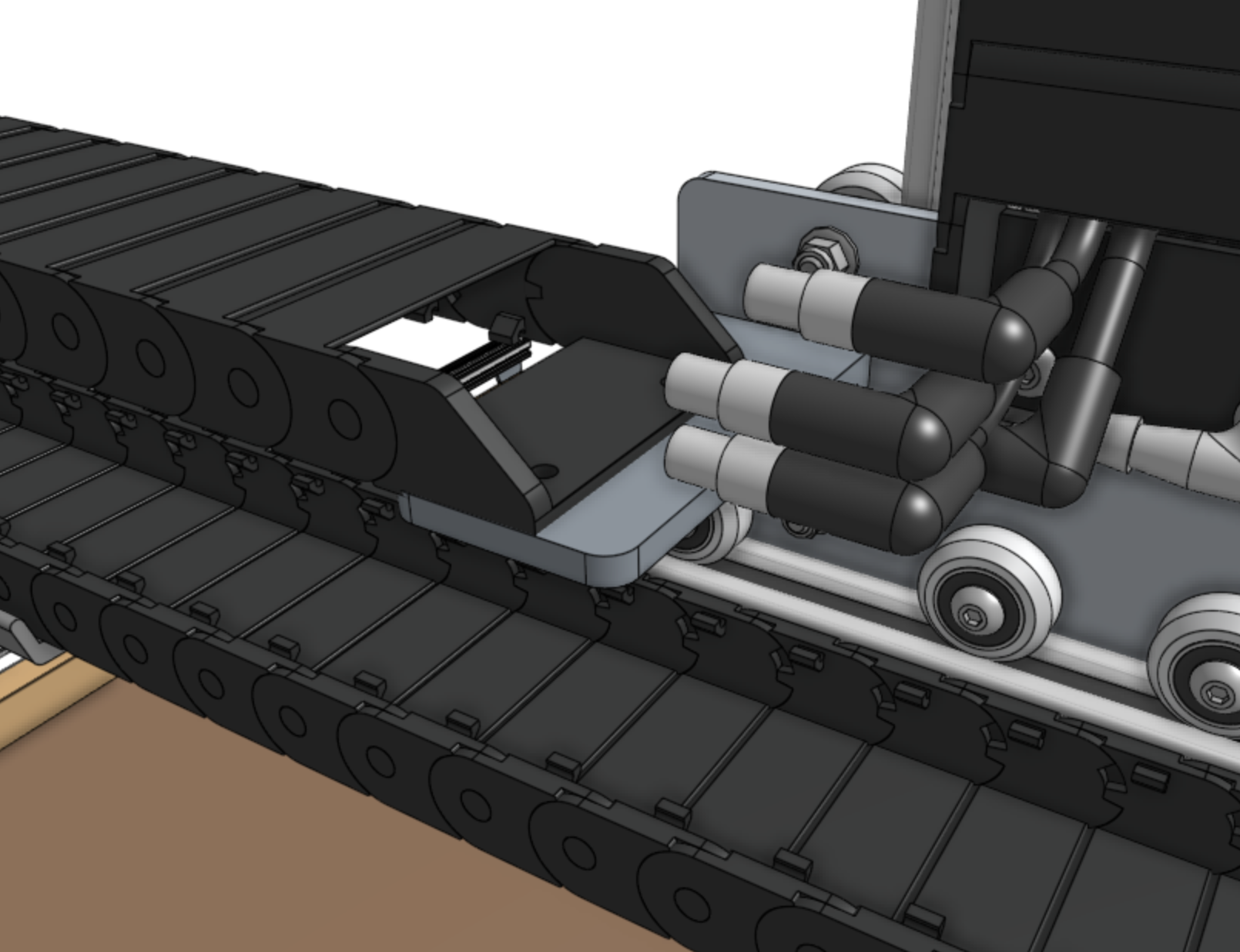

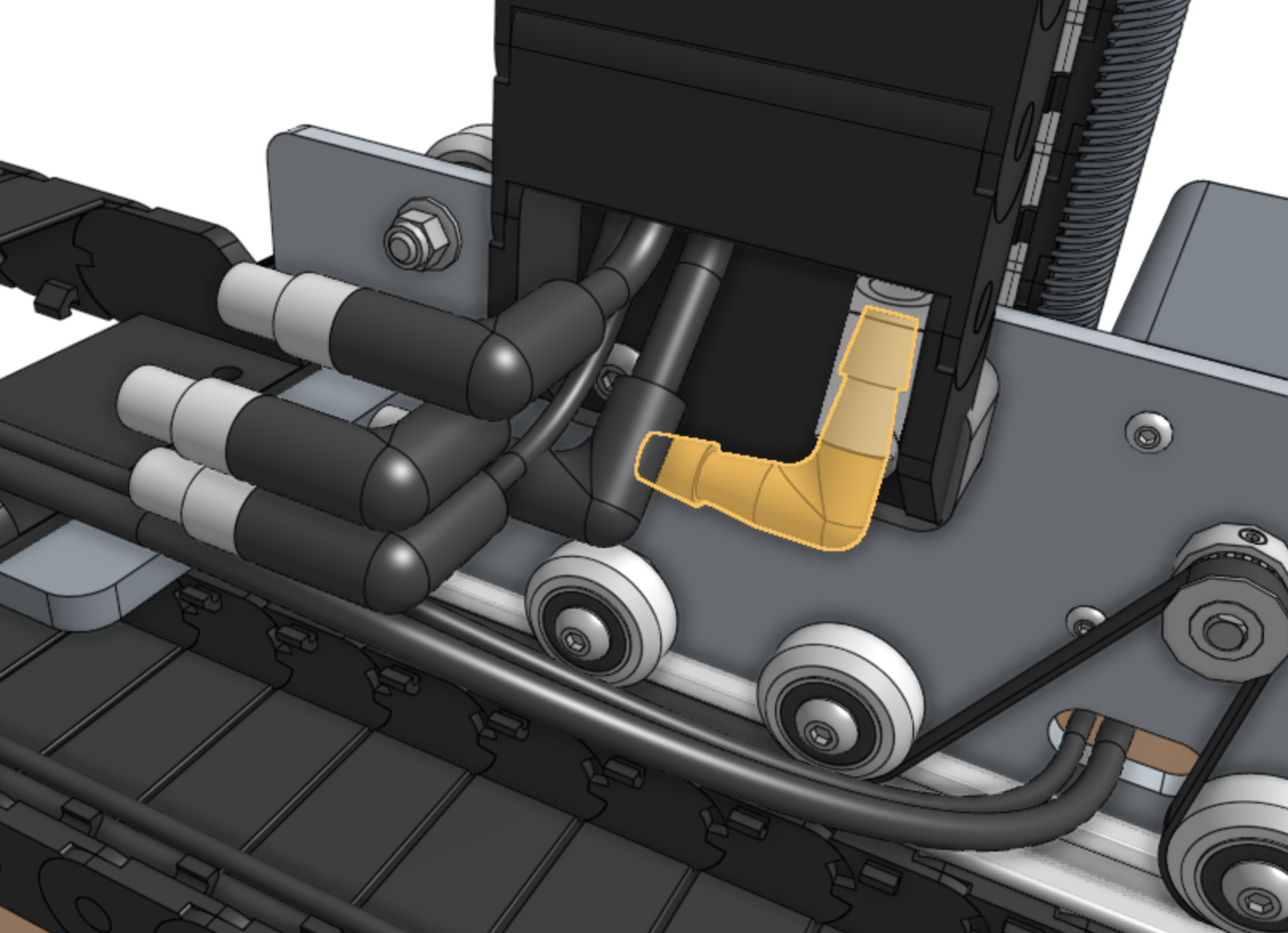

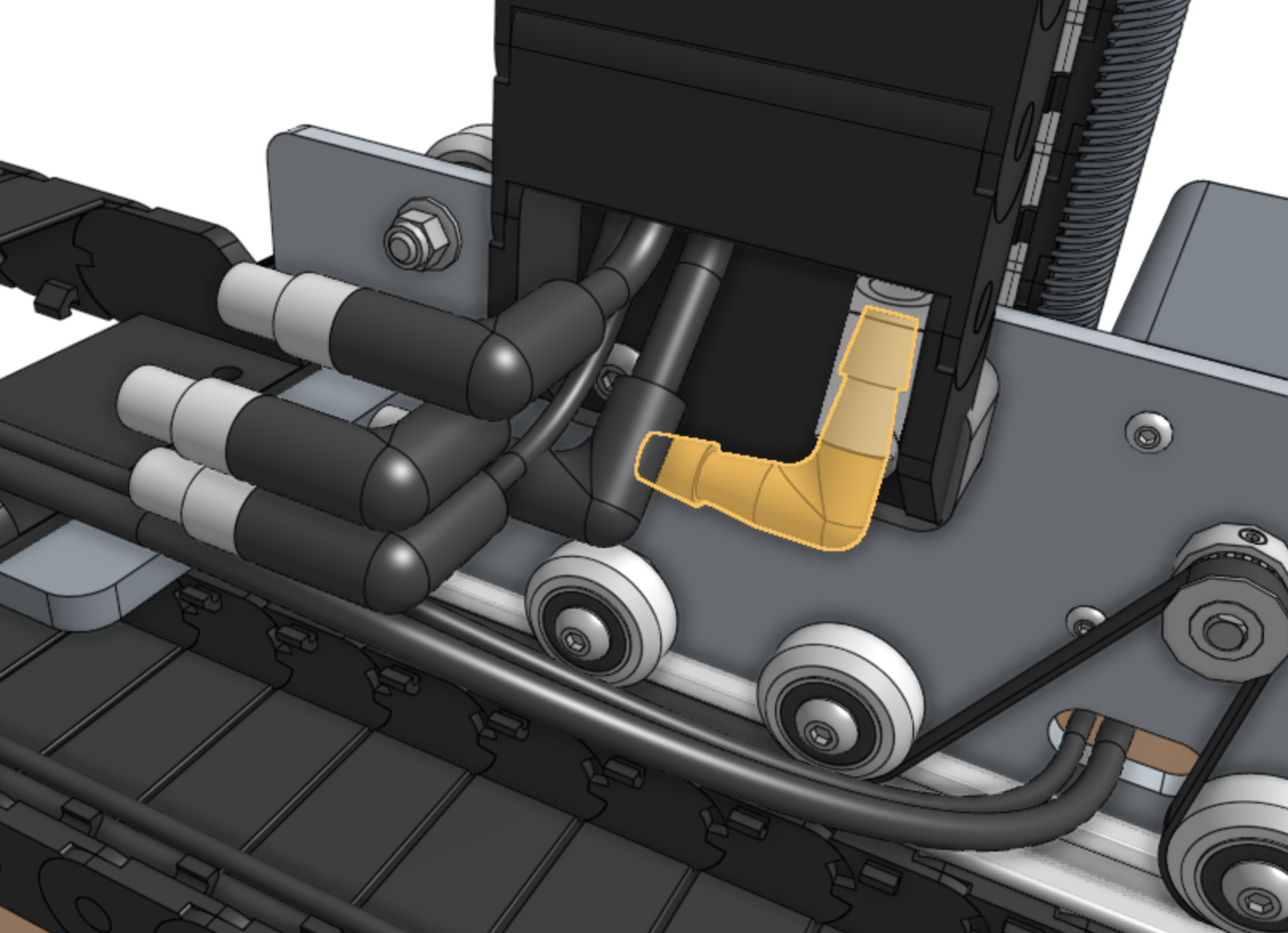

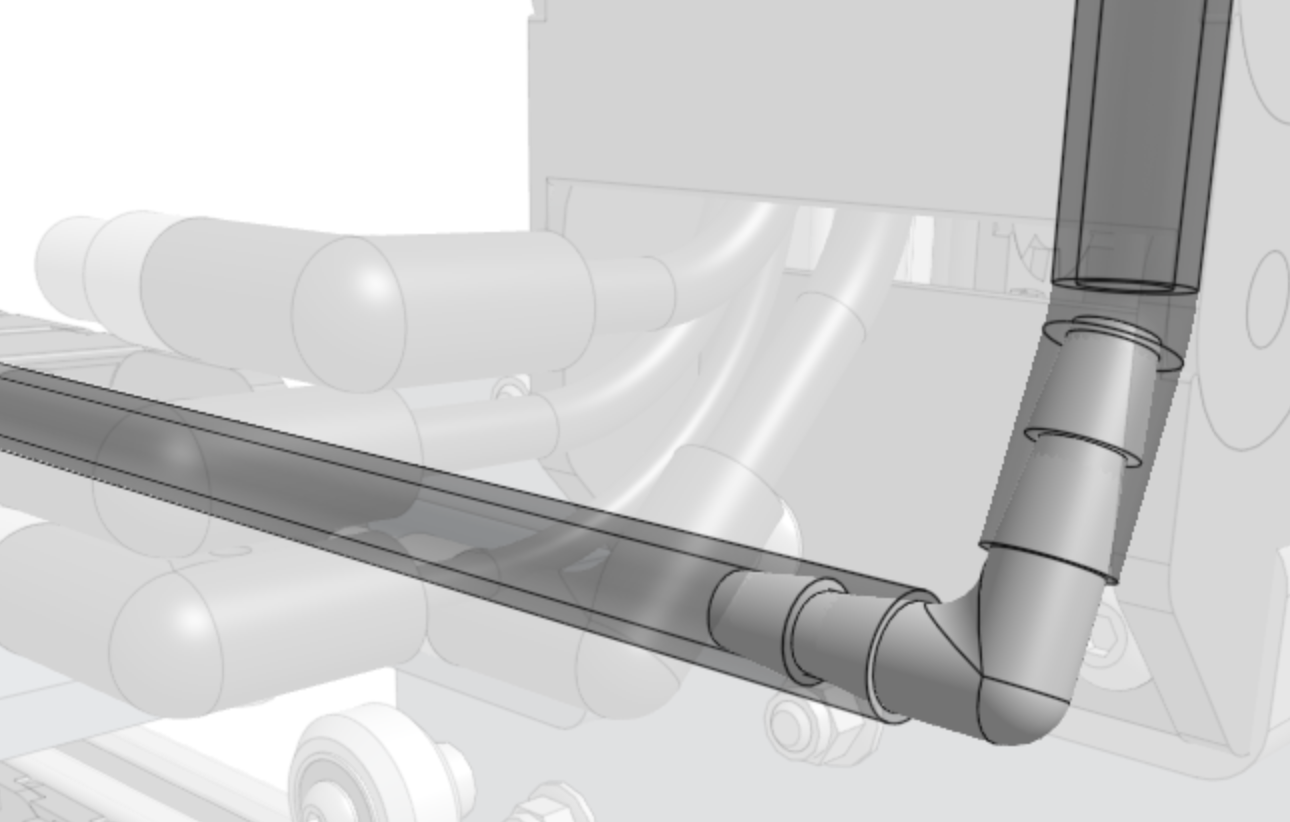

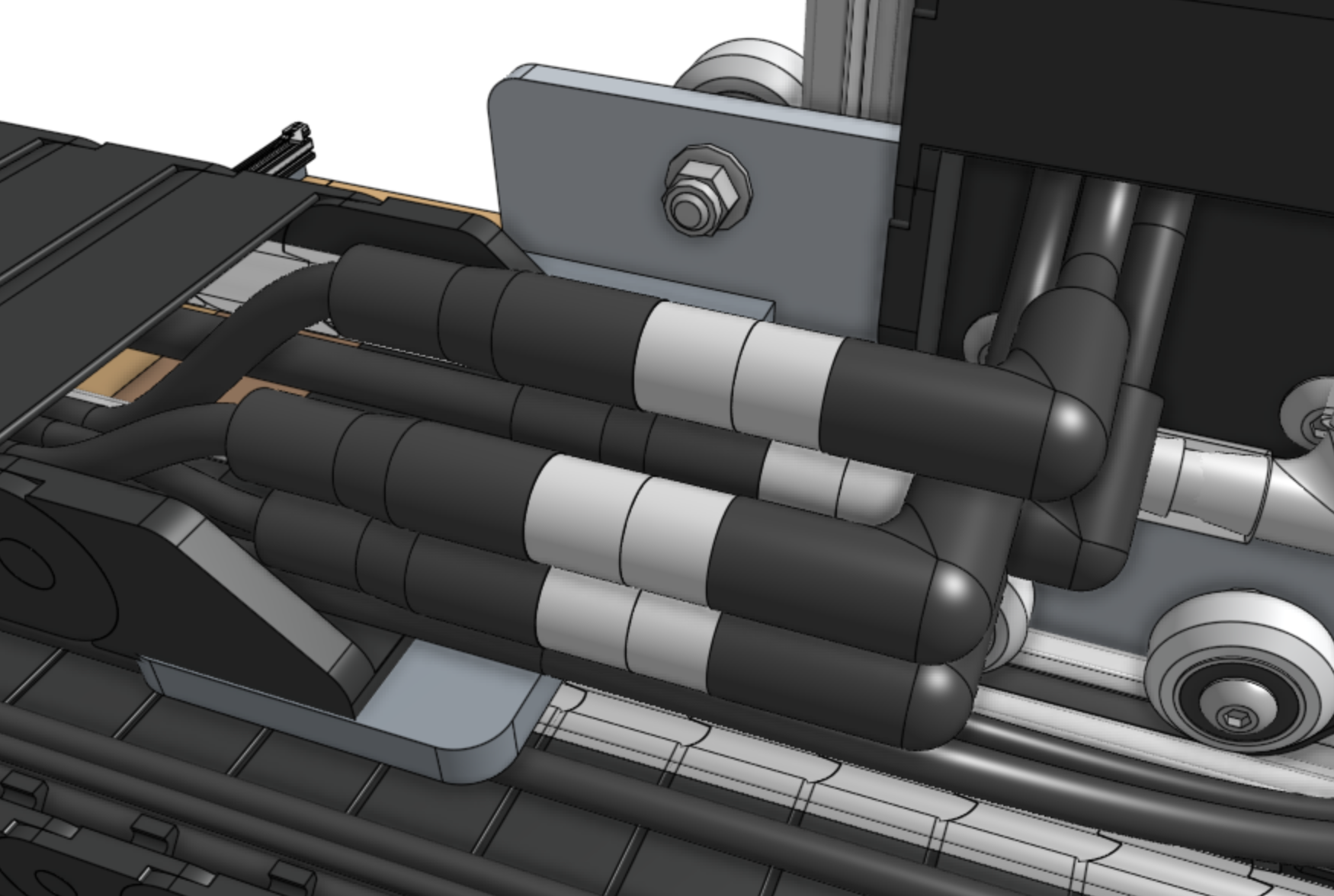

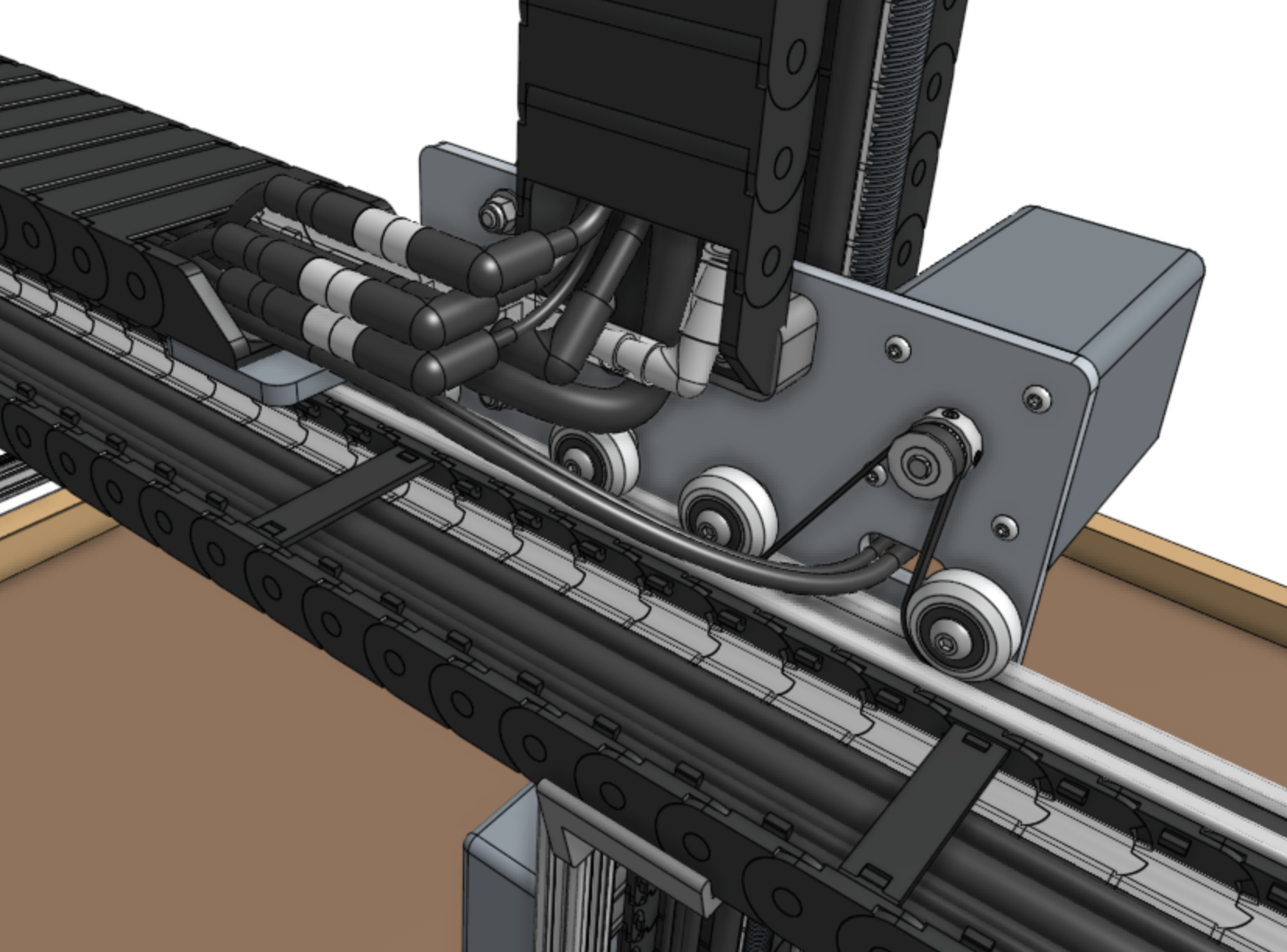

Step 4: Connect the tubing

Push the 90 degree barb onto the z-axis water tube. Then push the y-axis water tube onto the other end of the barb.

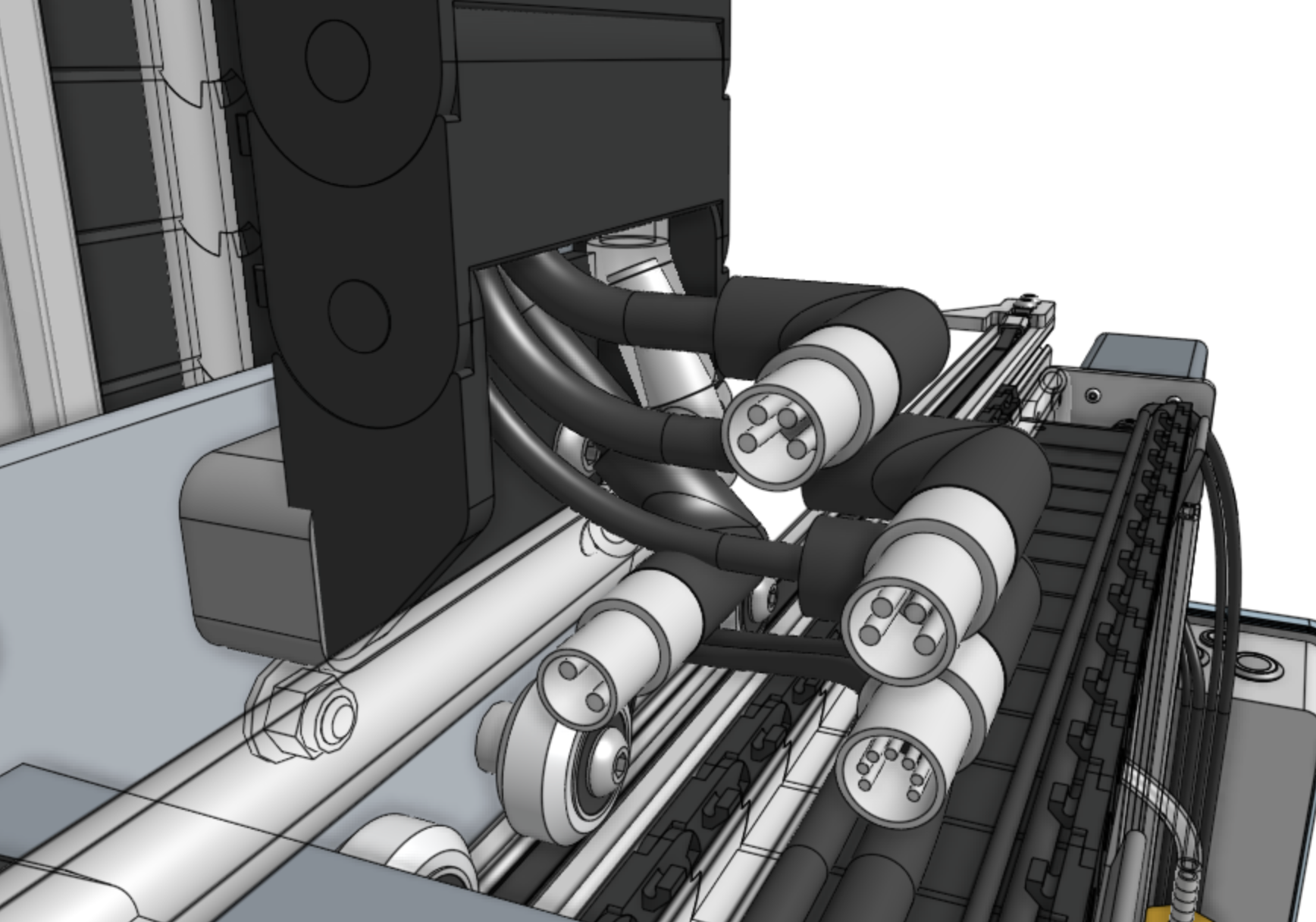

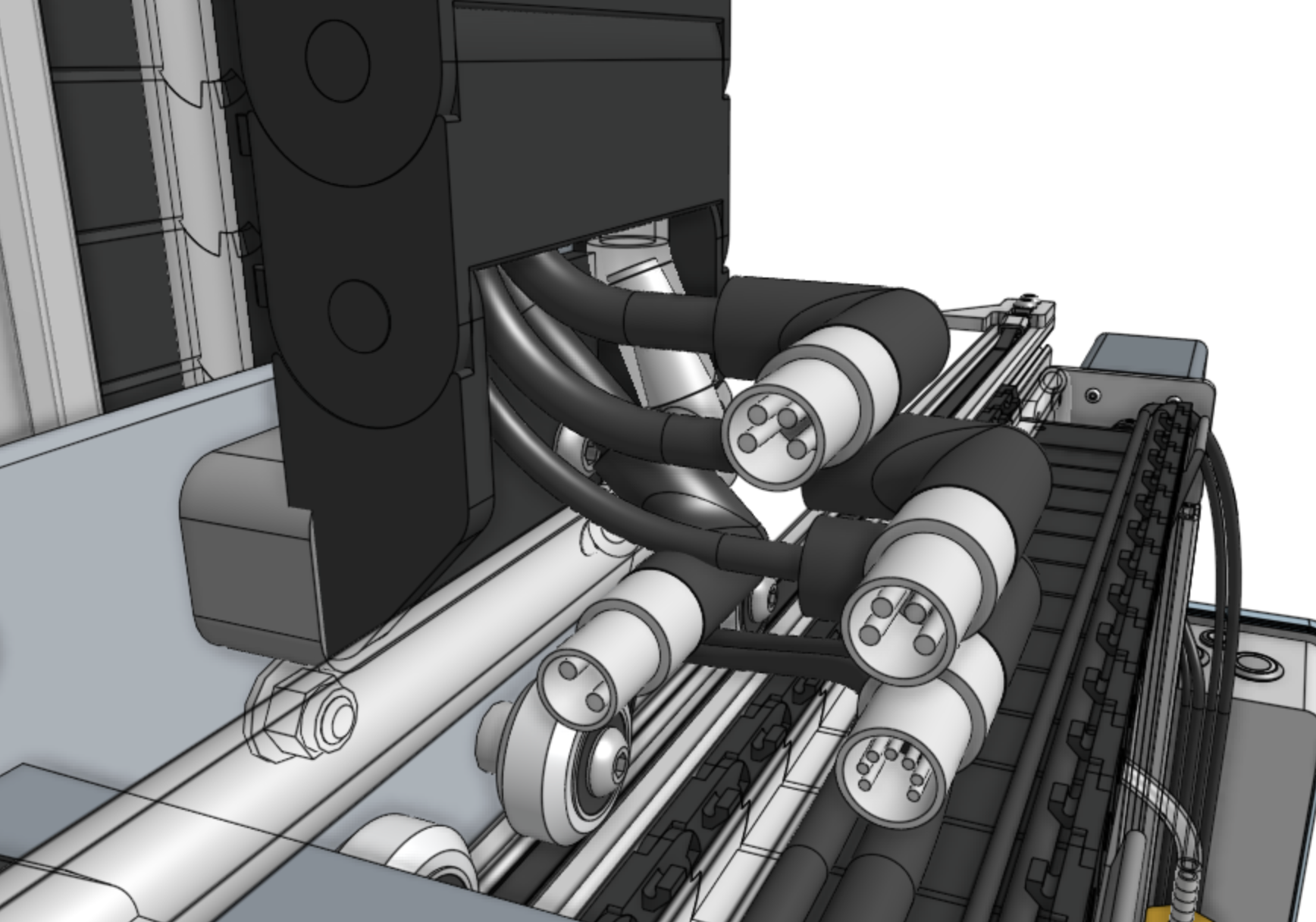

Step 5: Connect the cabling

Connect the z-axis and y-axis sections of the following cables together:

- Vacuum pump cable (z-axis section) to vacuum pump cable (y-axis section) with the 2-pin 90-degree connector

- Z-axis encoder cable (z-axis section) to z-axis encoder cable (y-axis section) with the 7-pin 90-degree connector

- Z-axis motor cable (z-axis section) to z-axis motor cable (y-axis section) with the 4-pin 90-degree connector

- Camera to camera cable with the 4-pin 90-degree connector

CAUTION: The camera and z-axis motor cables use the same connectors

Note that the camera and z-axis motor cables use the same connectors. When connecting the ends coming from the y-axis cable carrier to the ends coming from the z-axis cable carrier, ensure you are connecting camera to camera and z-axis motor to z-axis motor.

You can check to see which cable is which by tugging on a cable on one end of the cable carrier and seeing which cable moves on the other end.

We strongly recommend you take your time with this step because a mistake could cause massive damage to your electronics.

Pay special attention that you fully insert the 90-degree connectors together. This may require a multi-step process of pushing together, slightly tightening the thumb screws, pushing together again, and tightening some more. See the video below for detail.

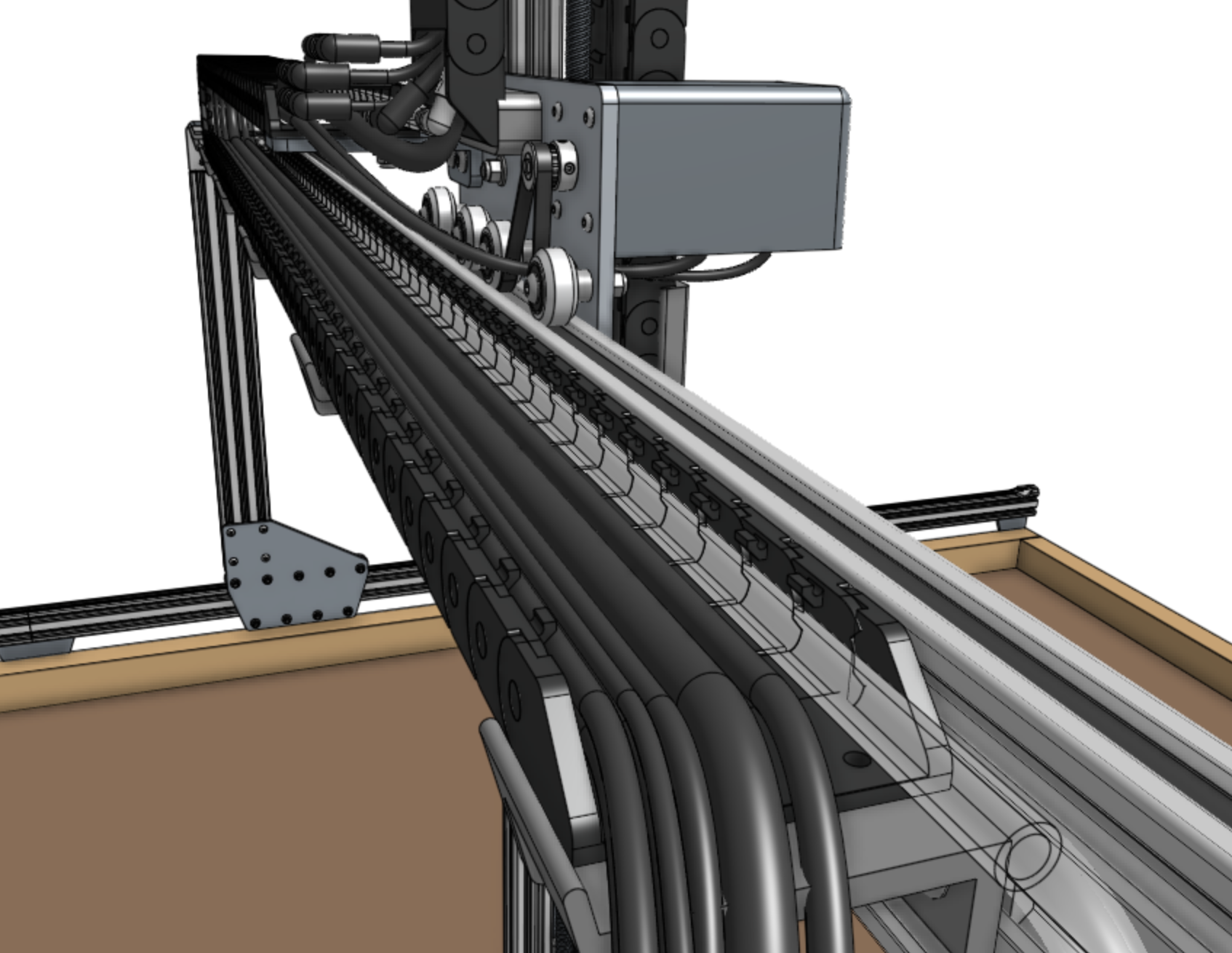

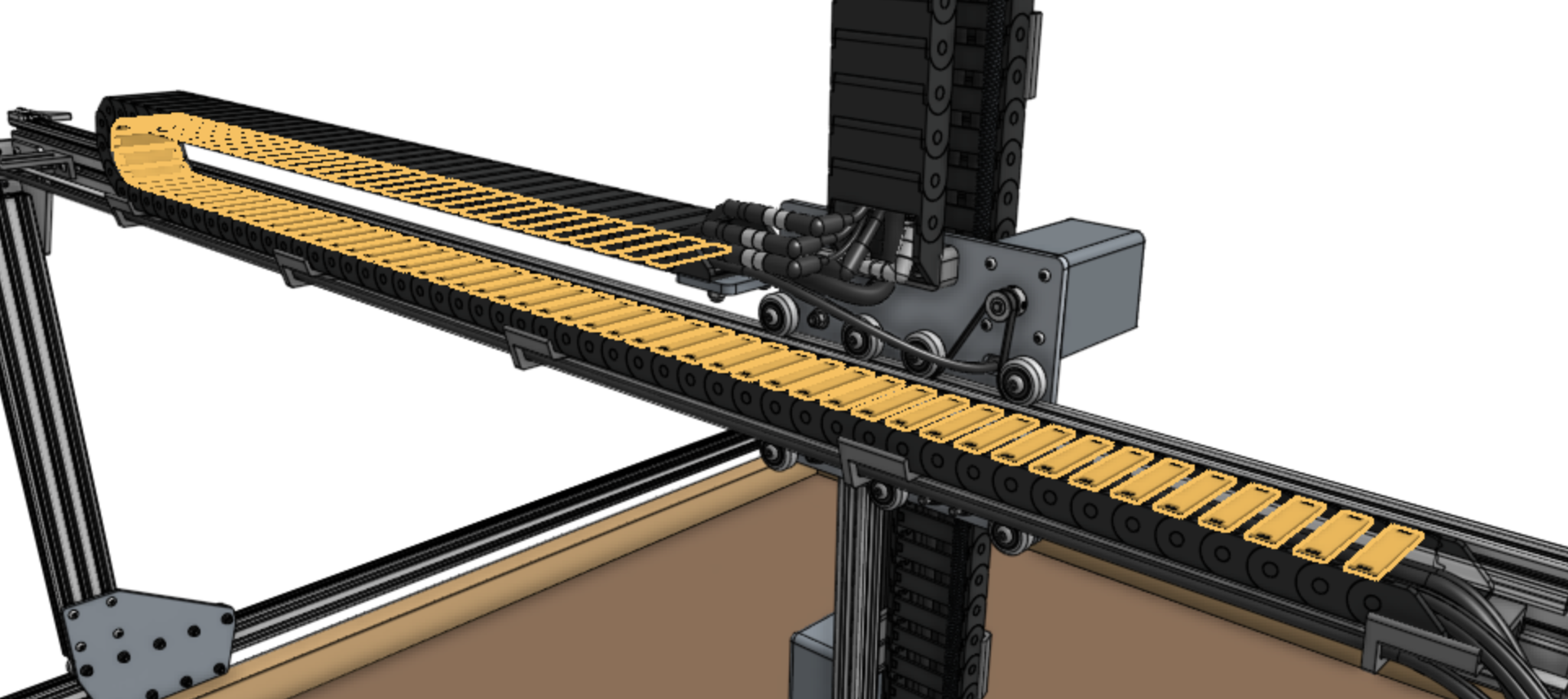

Step 6: Lay everything into the cable carrier

Neatly lay everything into the y-axis cable carrier:

- Y-axis motor cable

- Y-axis encoder cable

- Y-axis water tube

- UTM cable

- Camera cable (y-axis section)

- Vacuum pump cable (y-axis section)

- Z-axis motor cable (y-axis section)

- Z-axis encoder cable (y-axis section)

Organization is important!

When laying the cables and tube in the carrier, ensure that none of the items criss-cross over each other. If they do, you will have trouble snapping in the tabs and you risk compressing the tube and preventing water flow.

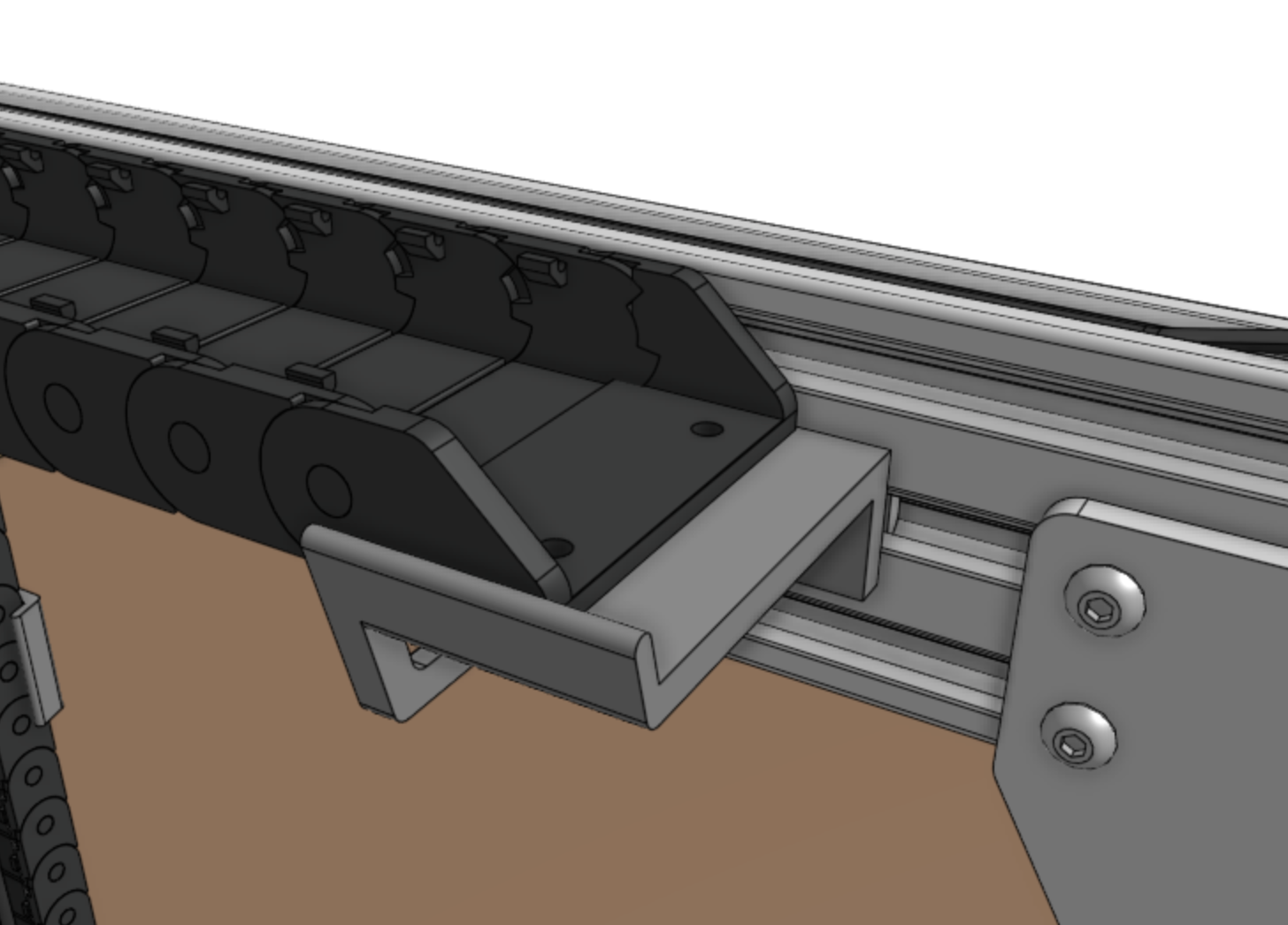

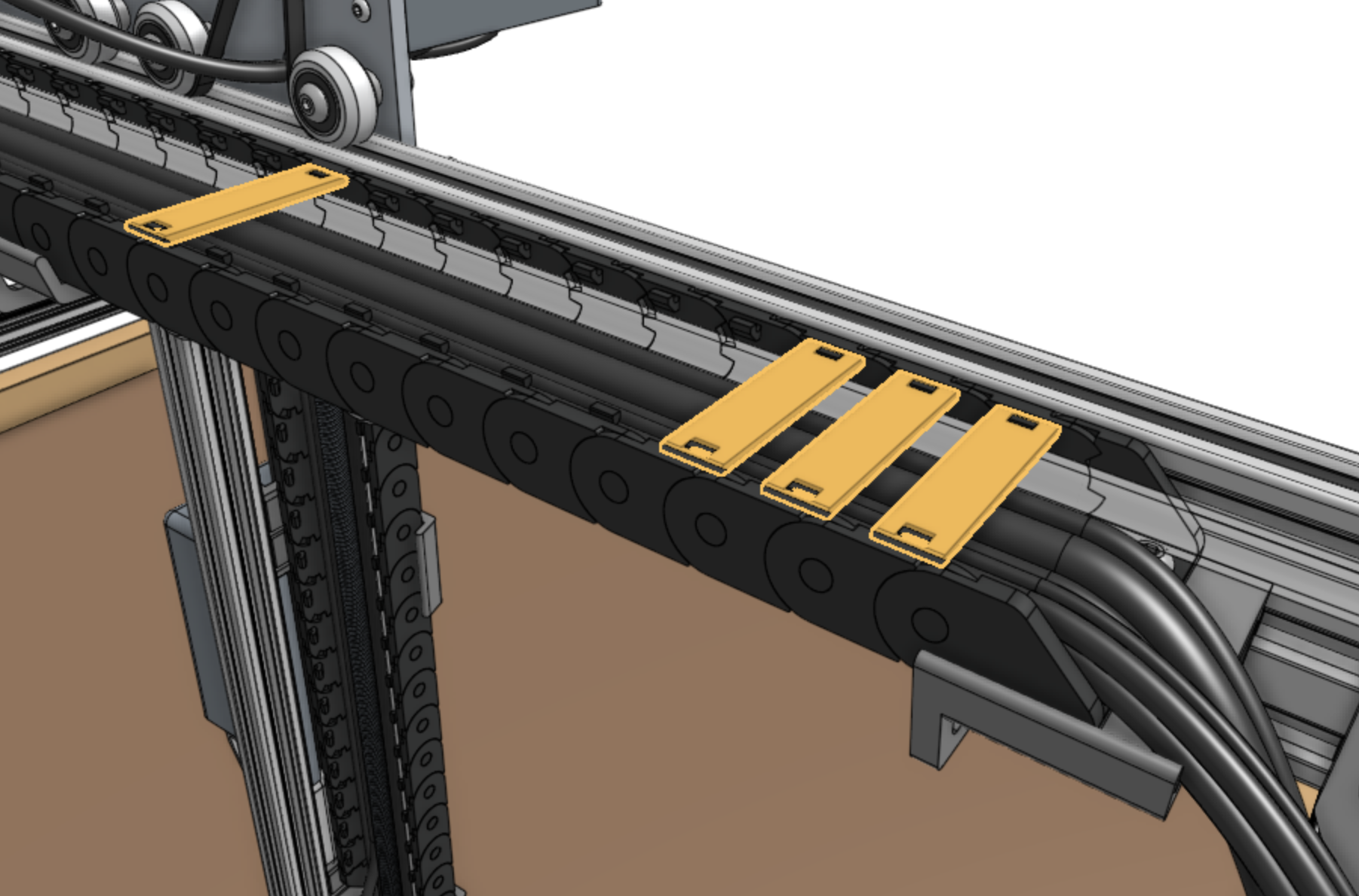

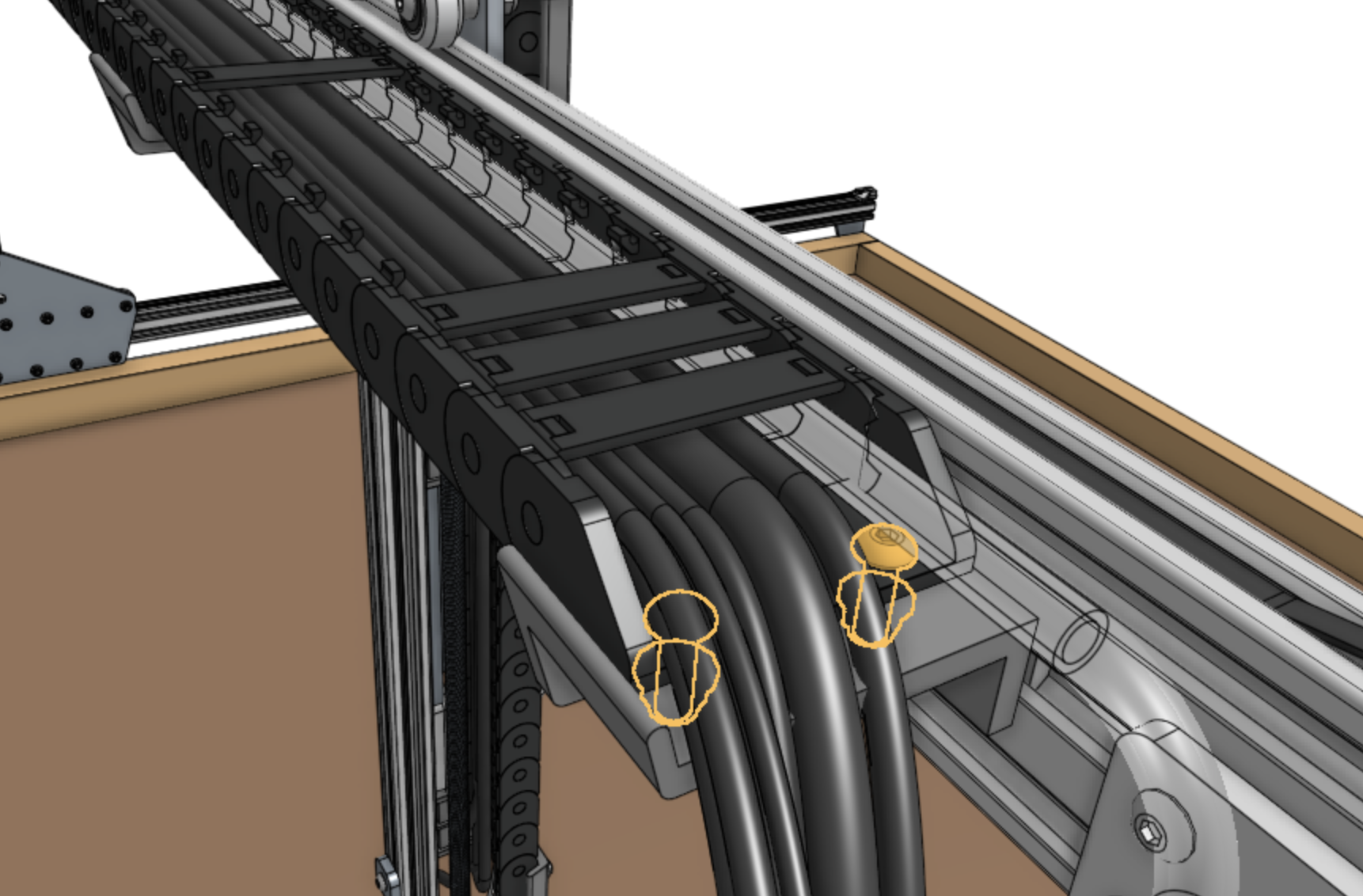

Step 7: Snap in some tabs

Snap in three cable carrier tabs at both ends of the cable carrier, and ten more spread throughout the middle of the cable carrier so that as you mount the assembly, the cables and tube will stay in place. You do not want to snap in all of the tabs at this time because that will make it difficult to adjust anything if needed.

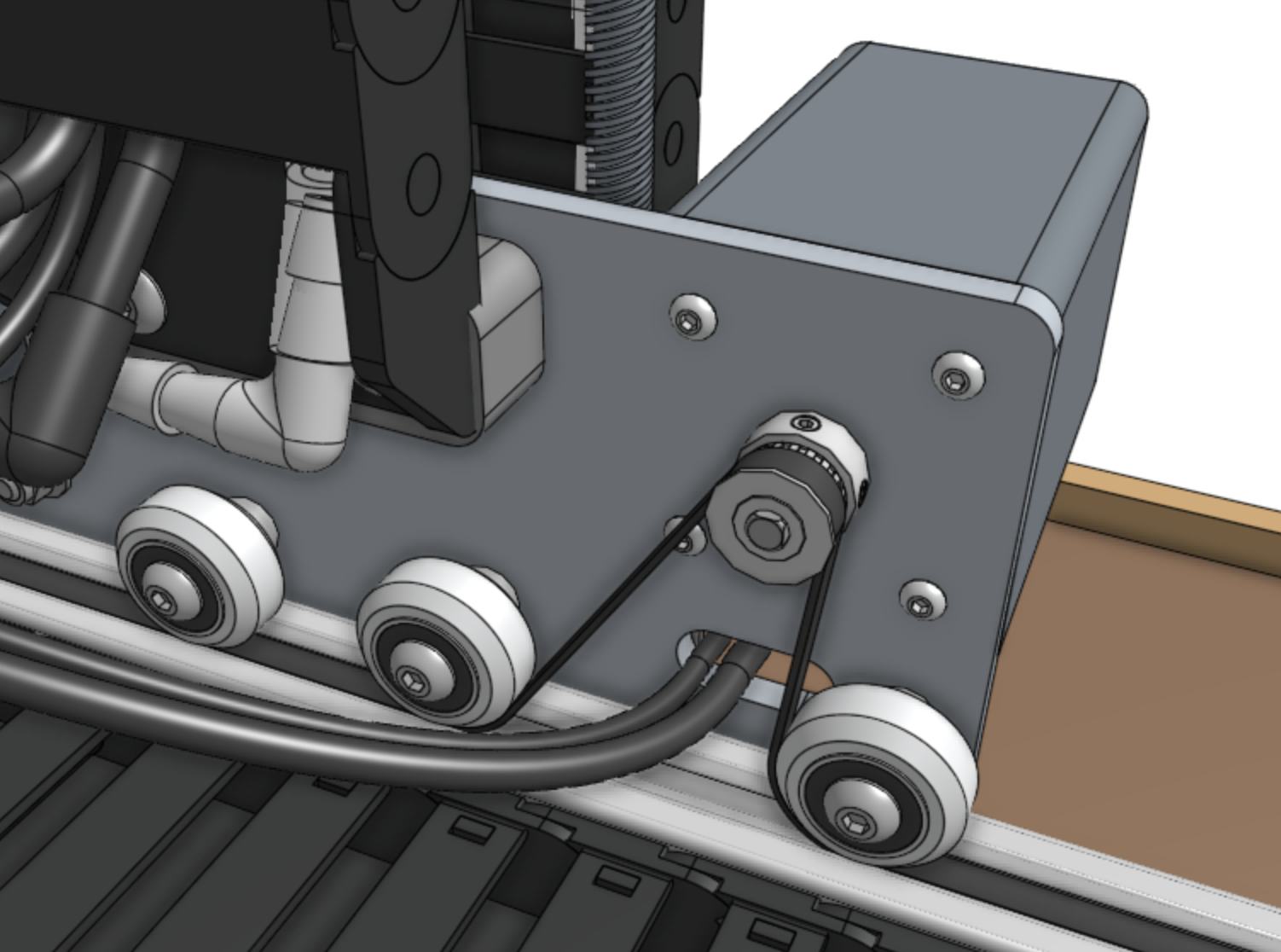

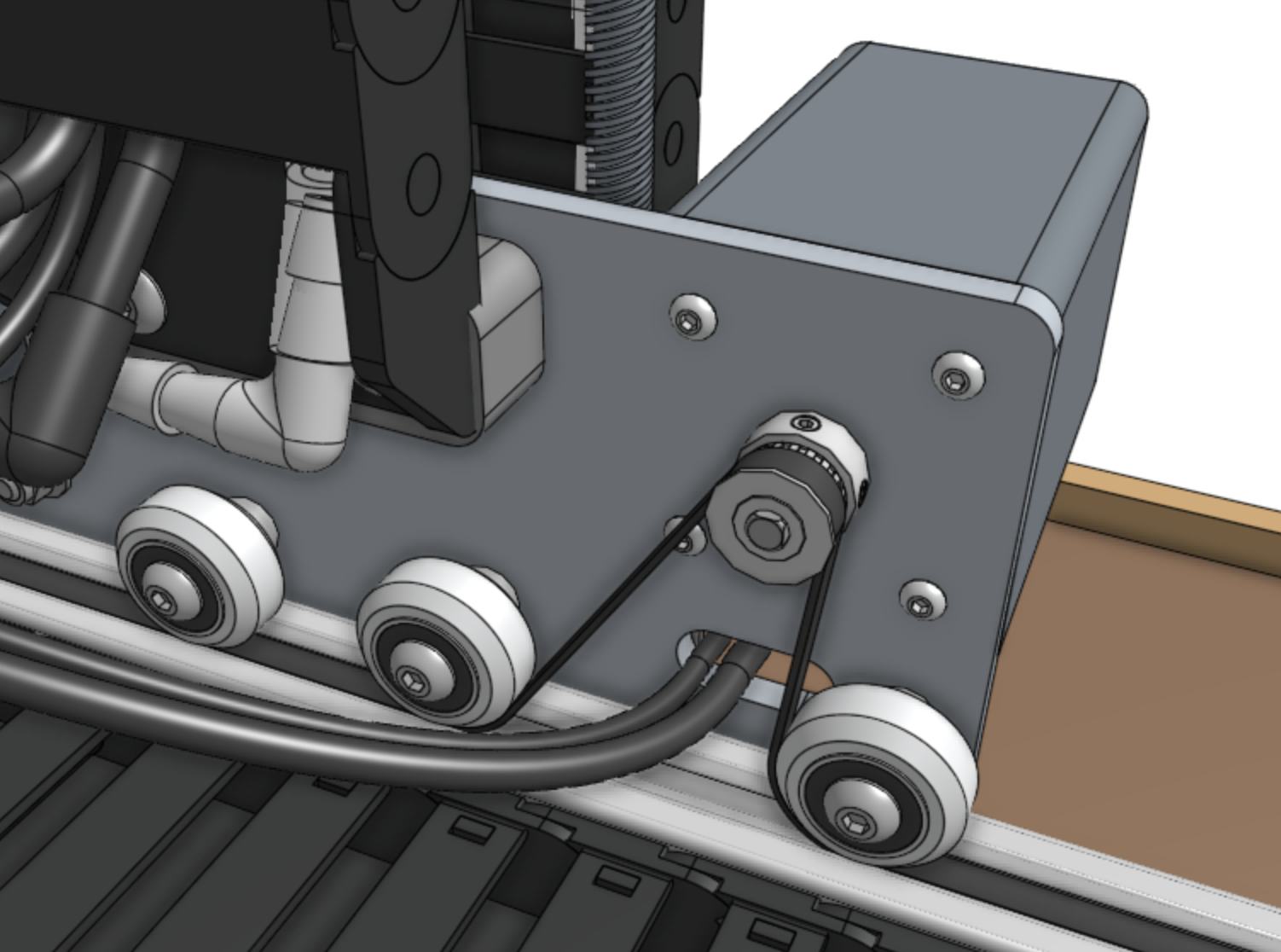

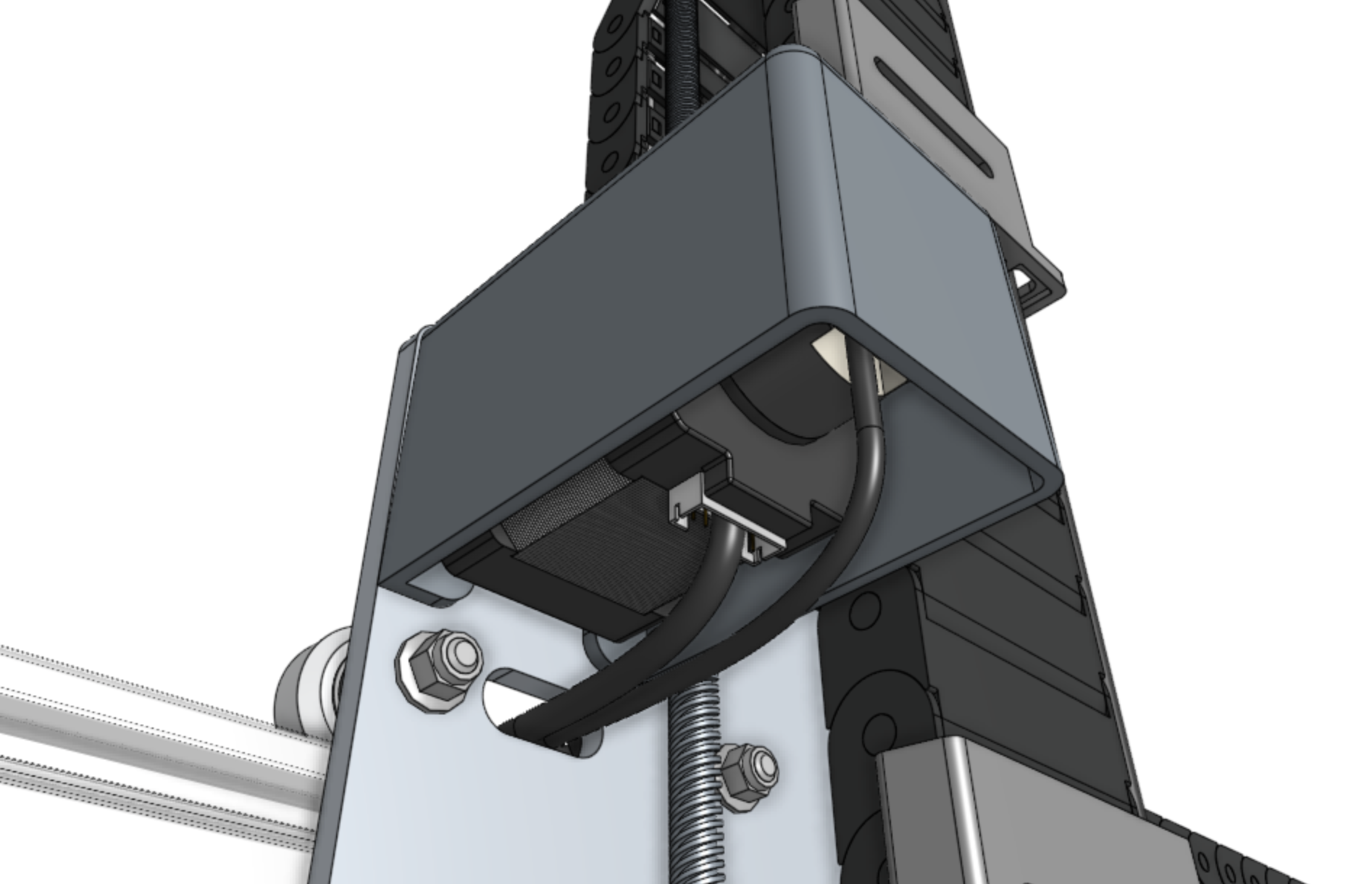

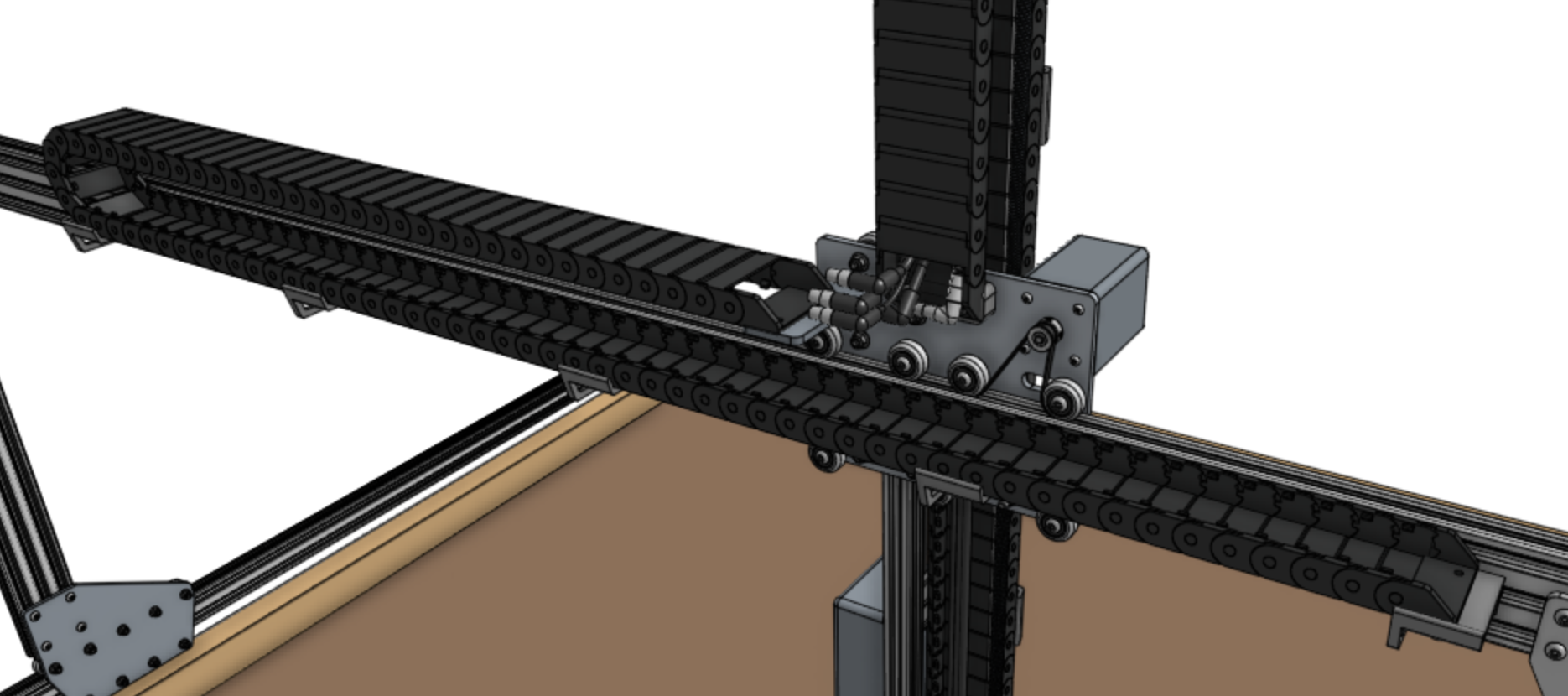

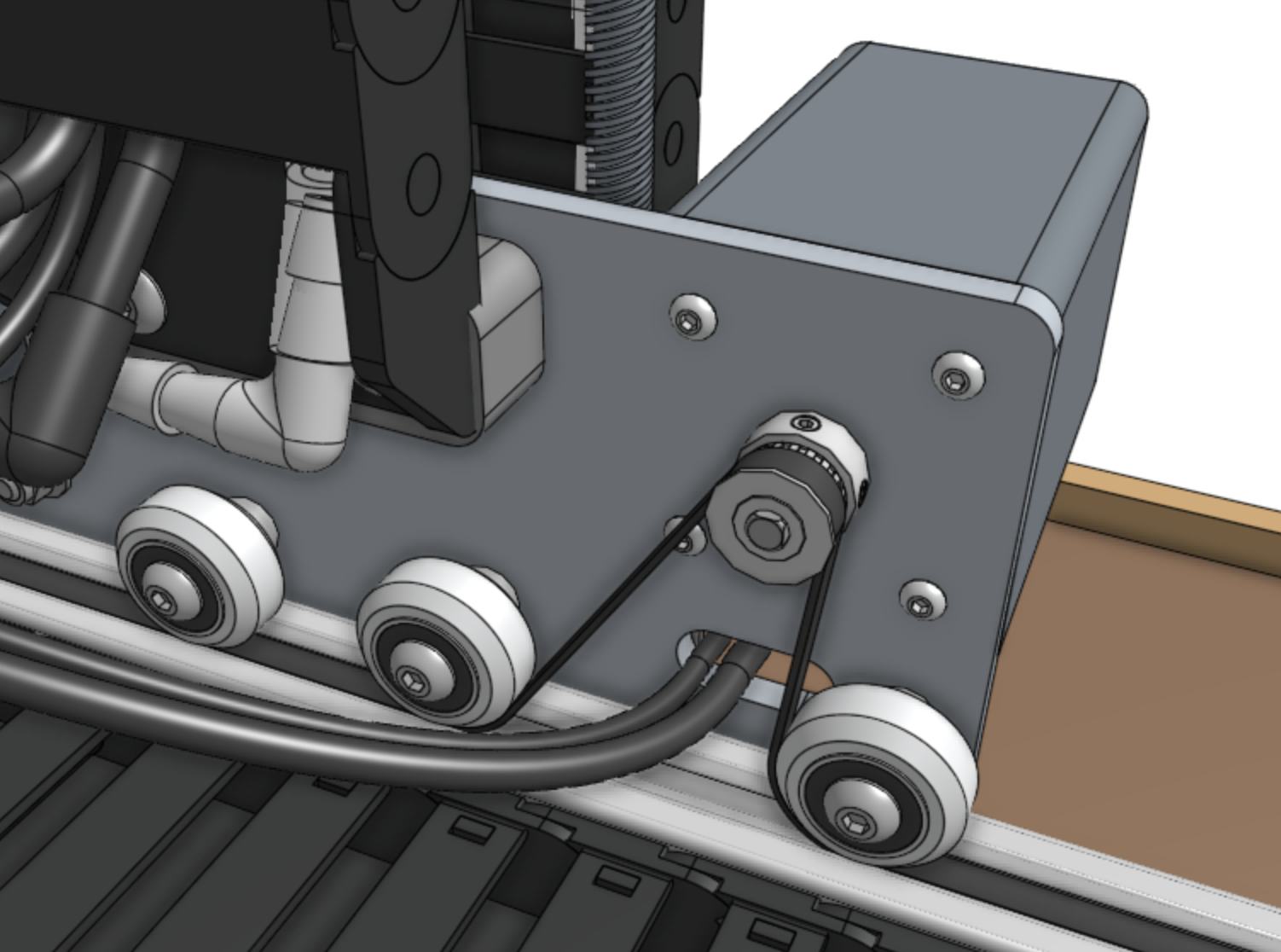

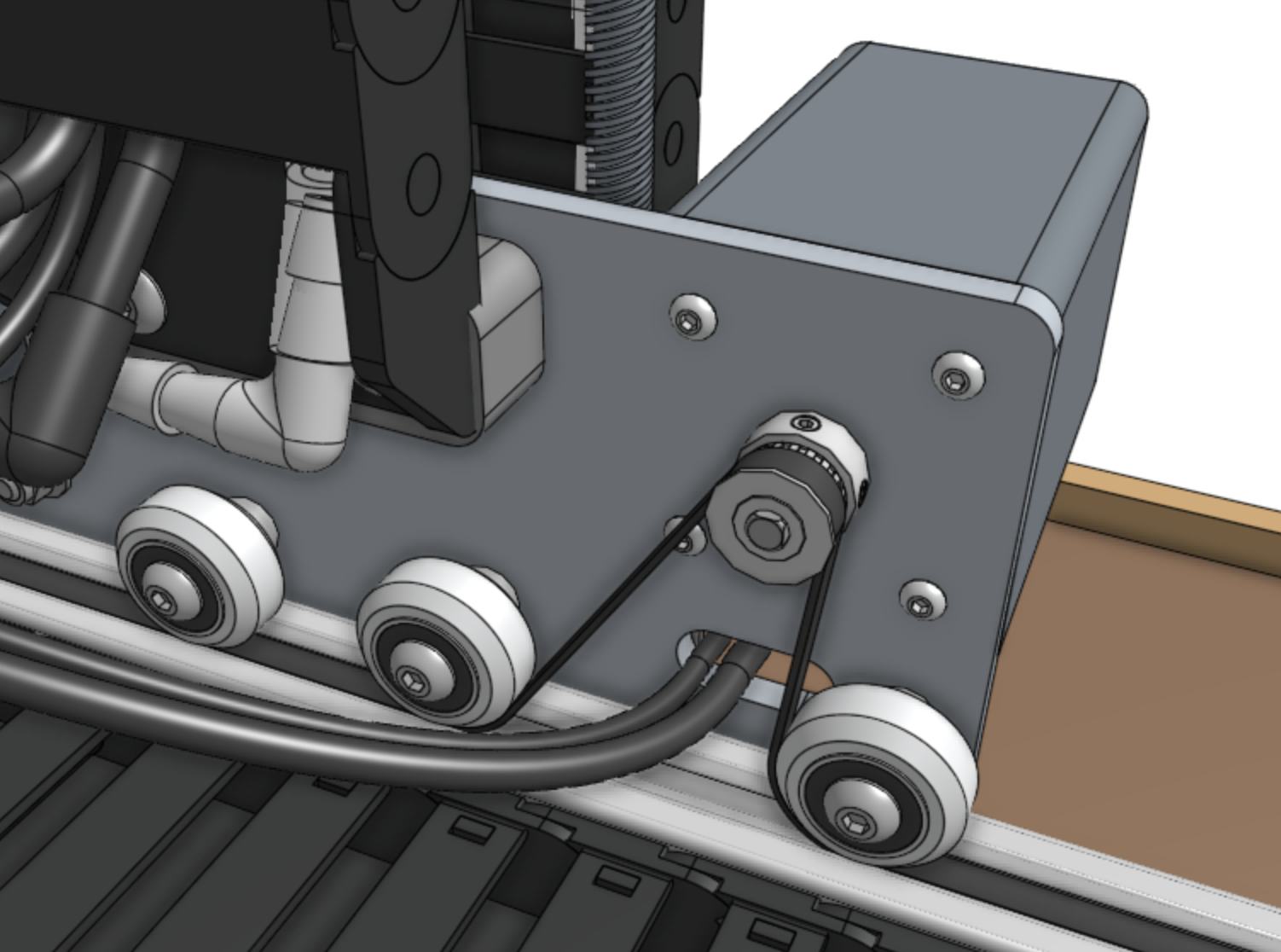

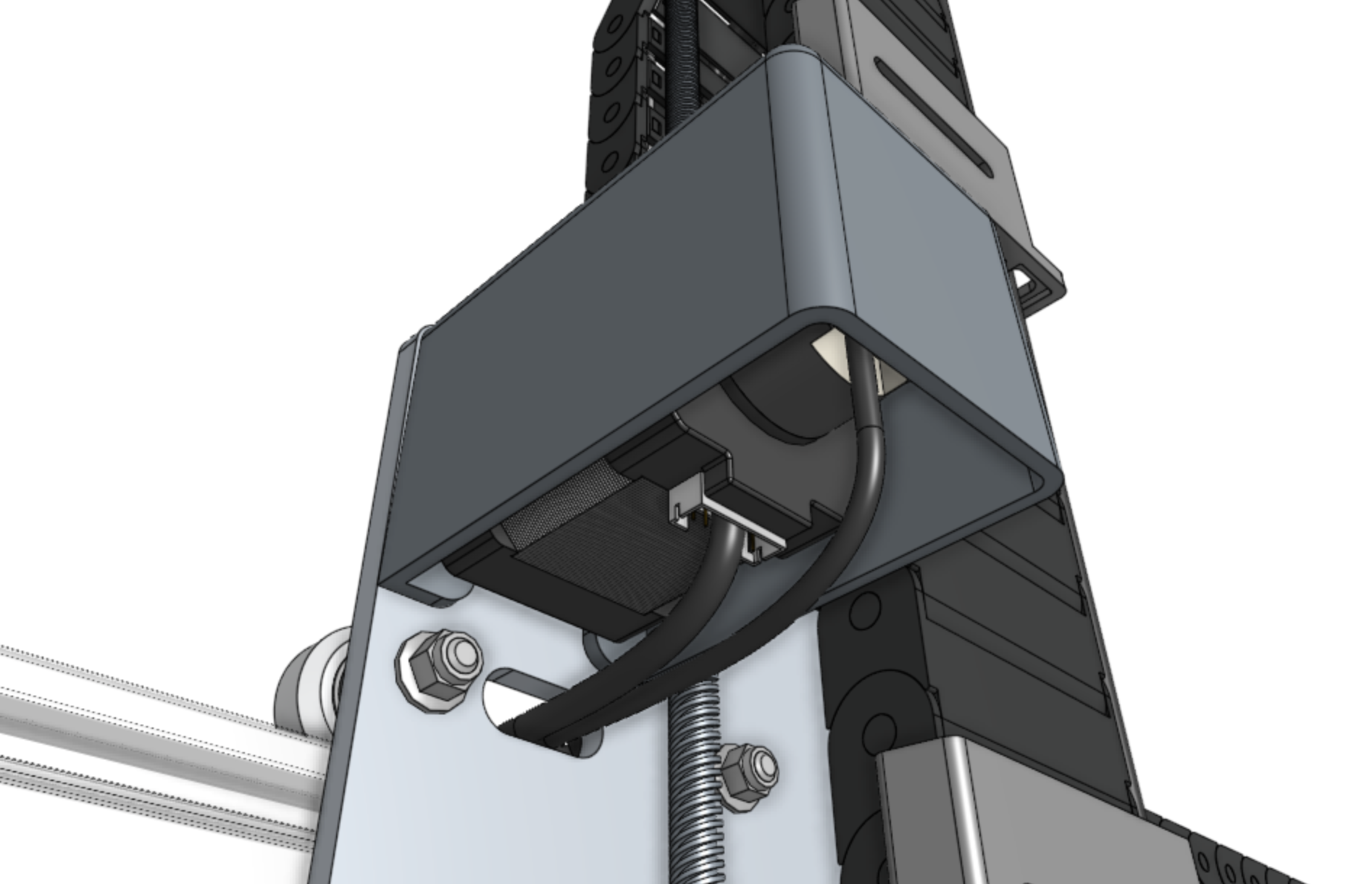

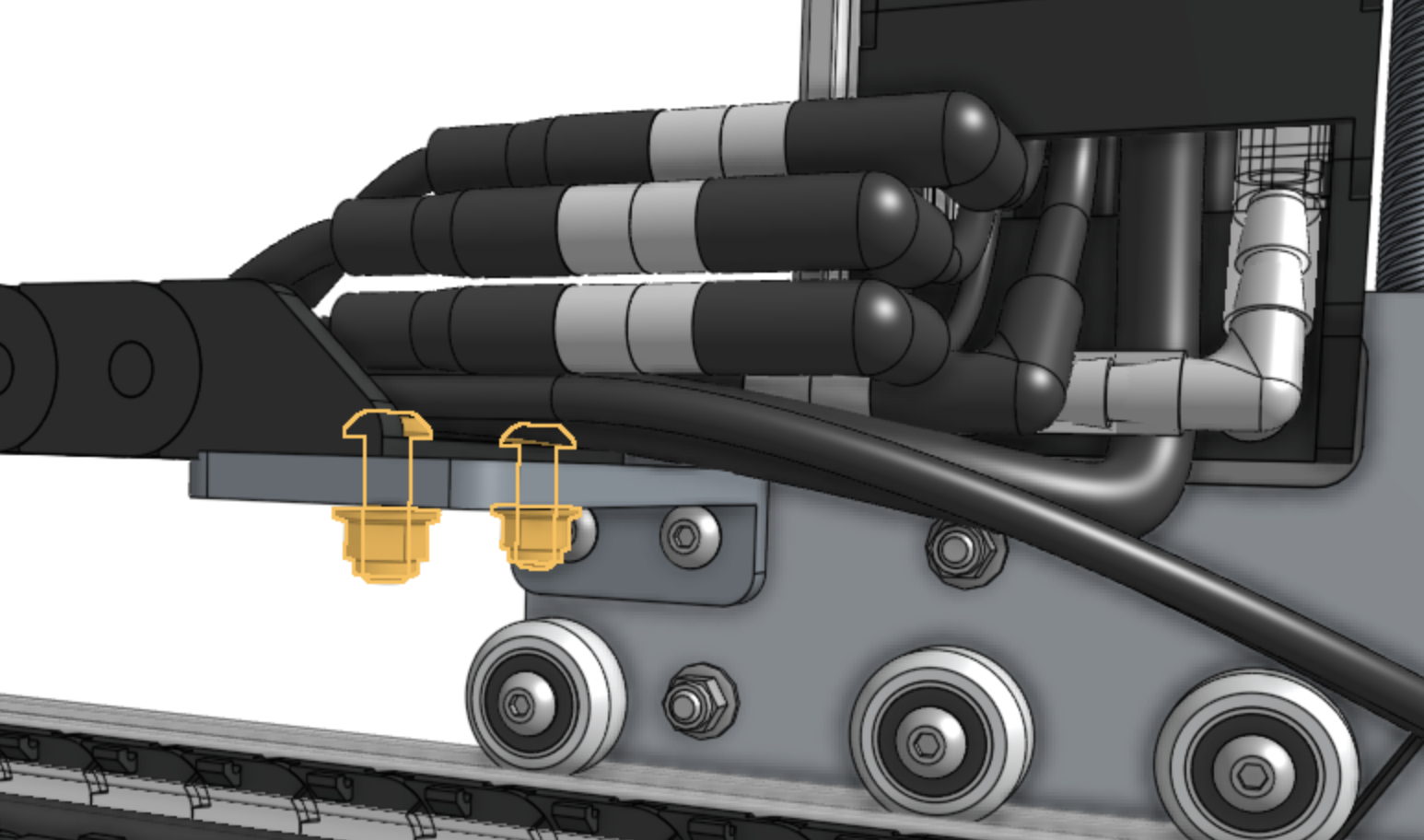

Step 8: Mount the cable carrier

Attach the y-axis cable carrier to the 80mm cable carrier mount using two M5 x 16mm screws and M5 flange locknuts. The screws should thread firmly through the cable carrier end piece.

Reduce the amount of extra tubing and wiring between the y-axis cable carrier and the z-axis cable carrier by gently pulling any extra cable or tubing length through the y-axis cable carrier. It can be difficult to coax the contents around the bend of the cable carrier, so take your time and ensure that you are not pulling anything too hard.

Never pull any cables by their connectors.

Attach the y-axis cable carrier to the 60mm horizontal cable carrier support nearest the left gantry column using two M5 x 16mm screws and M5 flange locknuts. The screws should thread firmly through the cable carrier end piece.

Step 9: Snap in the remaining tabs

Once everything is situated well, snap-in the remaining cable carrier tabs, ensuring that you maintain organization of the cables and tube.

Not easy to adjust

Once you snap-in the remaining tabs, it will become very difficult to adjust anything without removing the majority of the tabs first. Make sure everything is in place before snapping in all the tabs.

Step 10: Connect the y-axis motor and encoder

Connect the y-axis motor and encoder cables to the y-axis motor and encoder.

Clearance is key

Use zip ties and plenty of slack to ensure the motor and encoder wires do not rub against the belt.