Z-Axis

Documentation and assembly instructions for the FarmBot Genesis z-axis

- Step 1: Attach the stepper motor to the Z-axis motor mount

- Step 2: Attach the motor mount to the Z-axis extrusion

- Step 3: Attach the shaft coupling

- Step 4: Attach three cable carrier supports

- Step 5: Attach the vacuum pump cover

- Step 6: Attach the vacuum pump

- Step 7: Attach one more cable carrier support

- Step 8: Attach the z-axis to the cross-slide

- Step 9: Install the hardstops

- Step 10: Add the vertical motor housing (optional)

- What’s next?

1 hour

This is the estimated time it will take to assemble the z-axis.

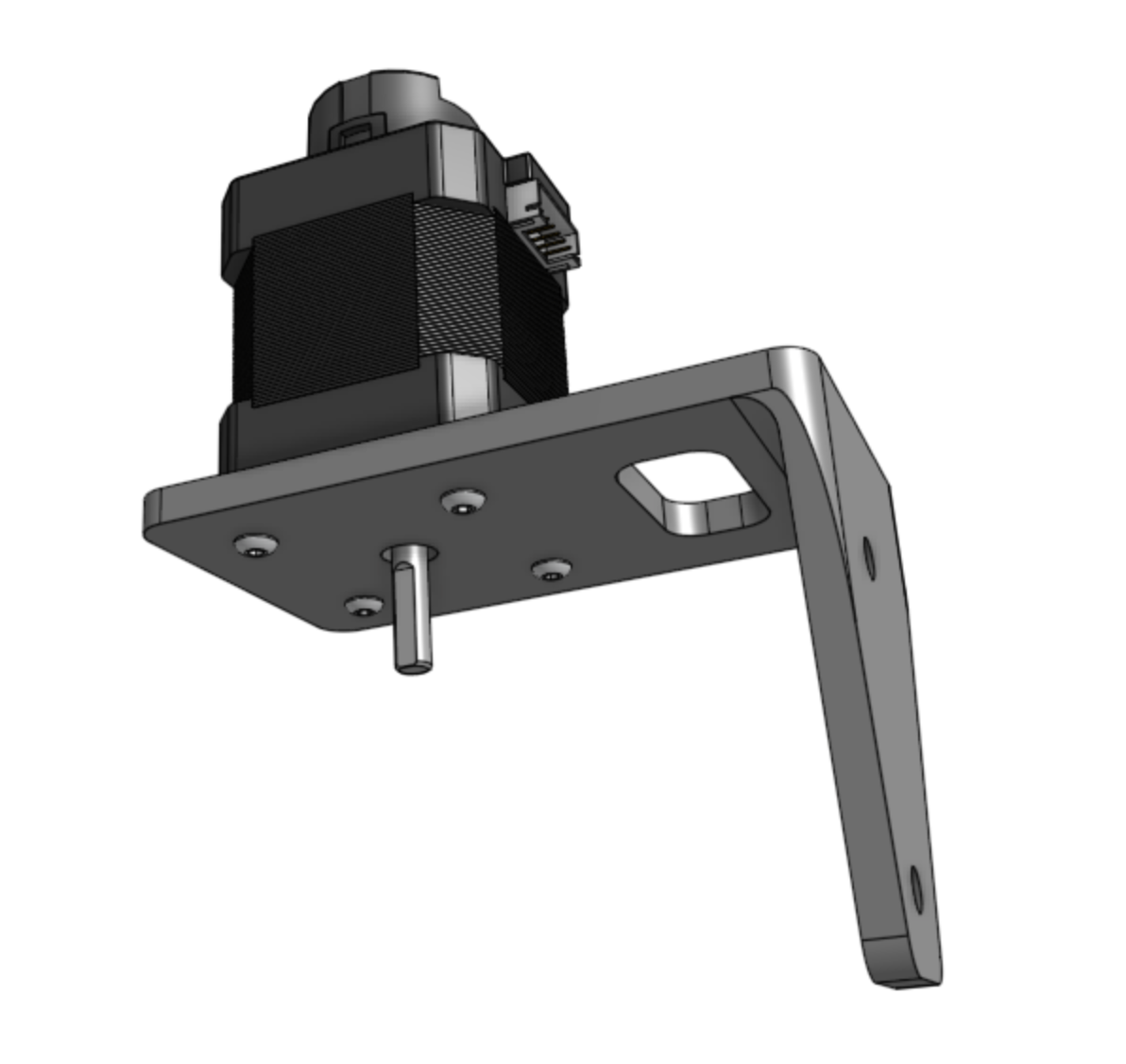

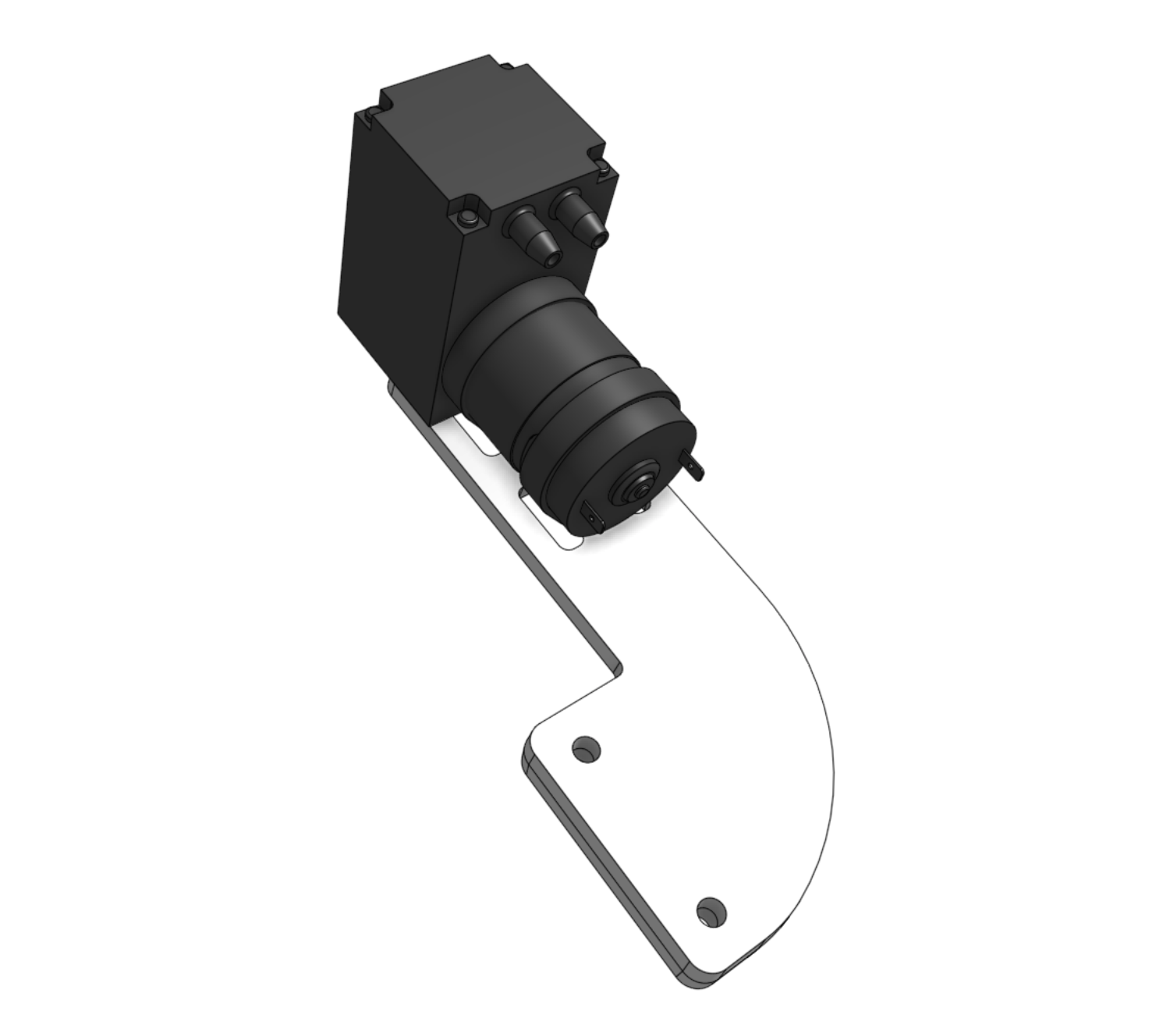

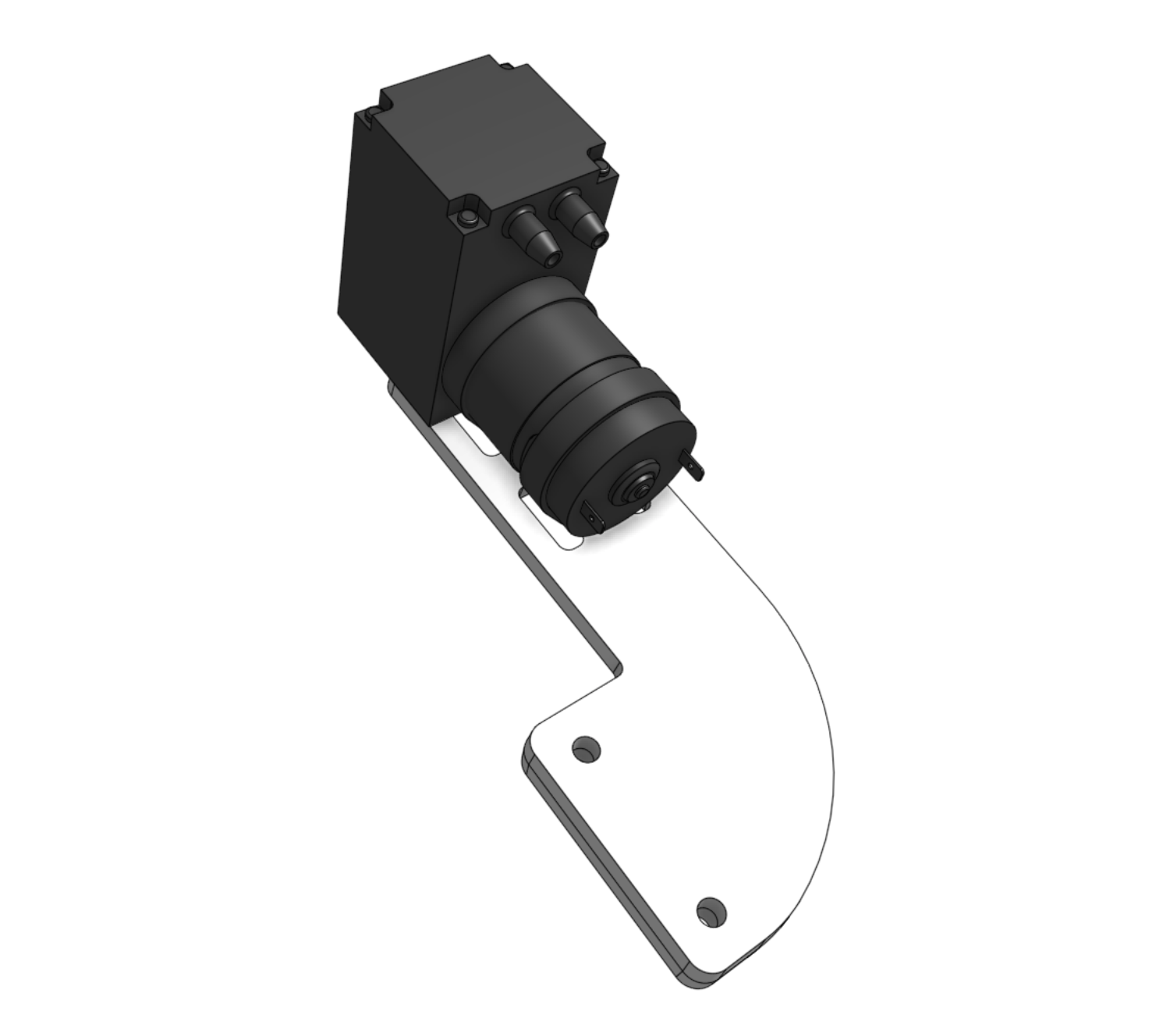

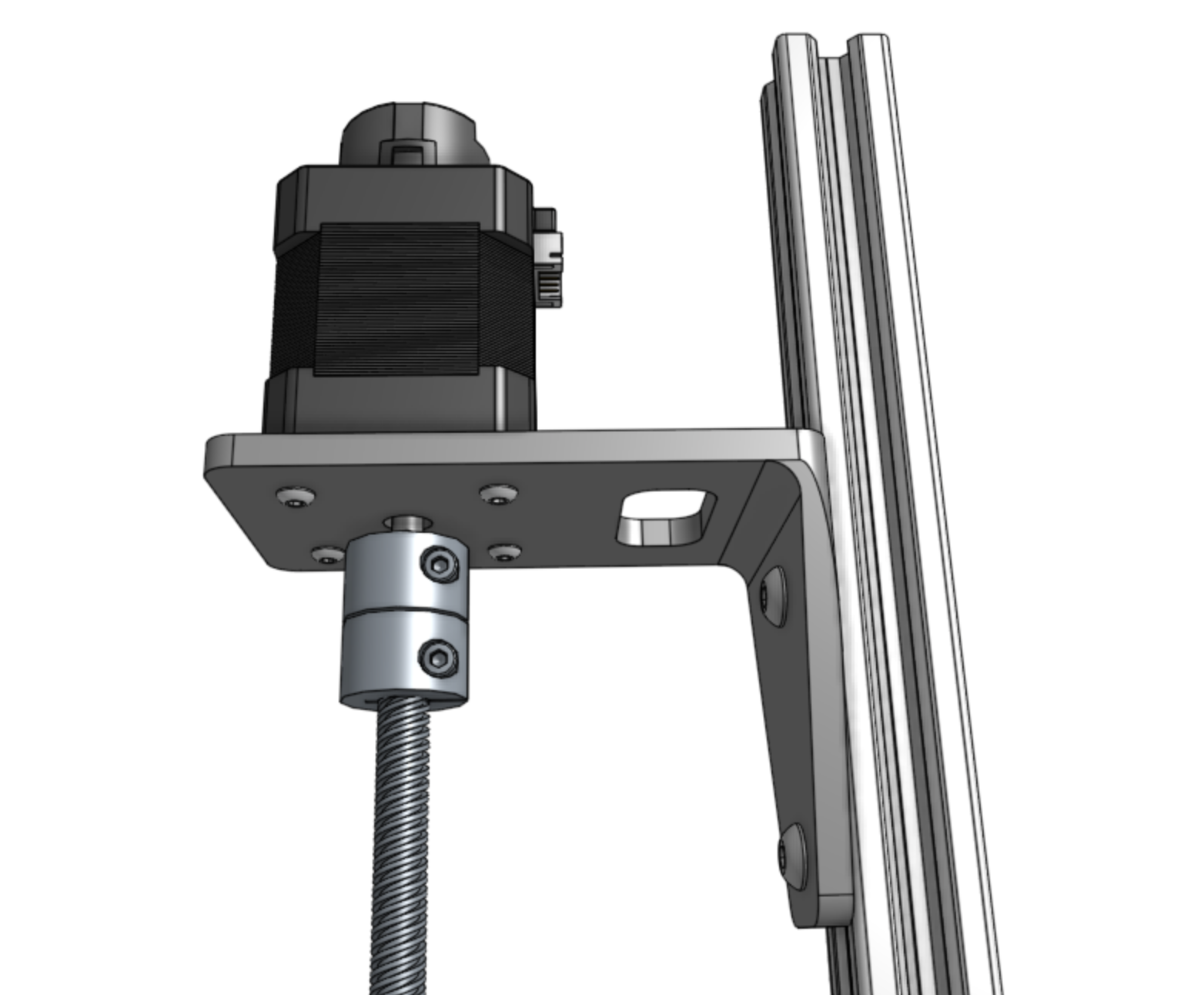

Step 1: Attach the stepper motor to the Z-axis motor mount

Attach a stepper motor to the z-axis motor mount using four M3 x 12mm screws. The motor and encoder connectors should be facing the back flange of the mount.

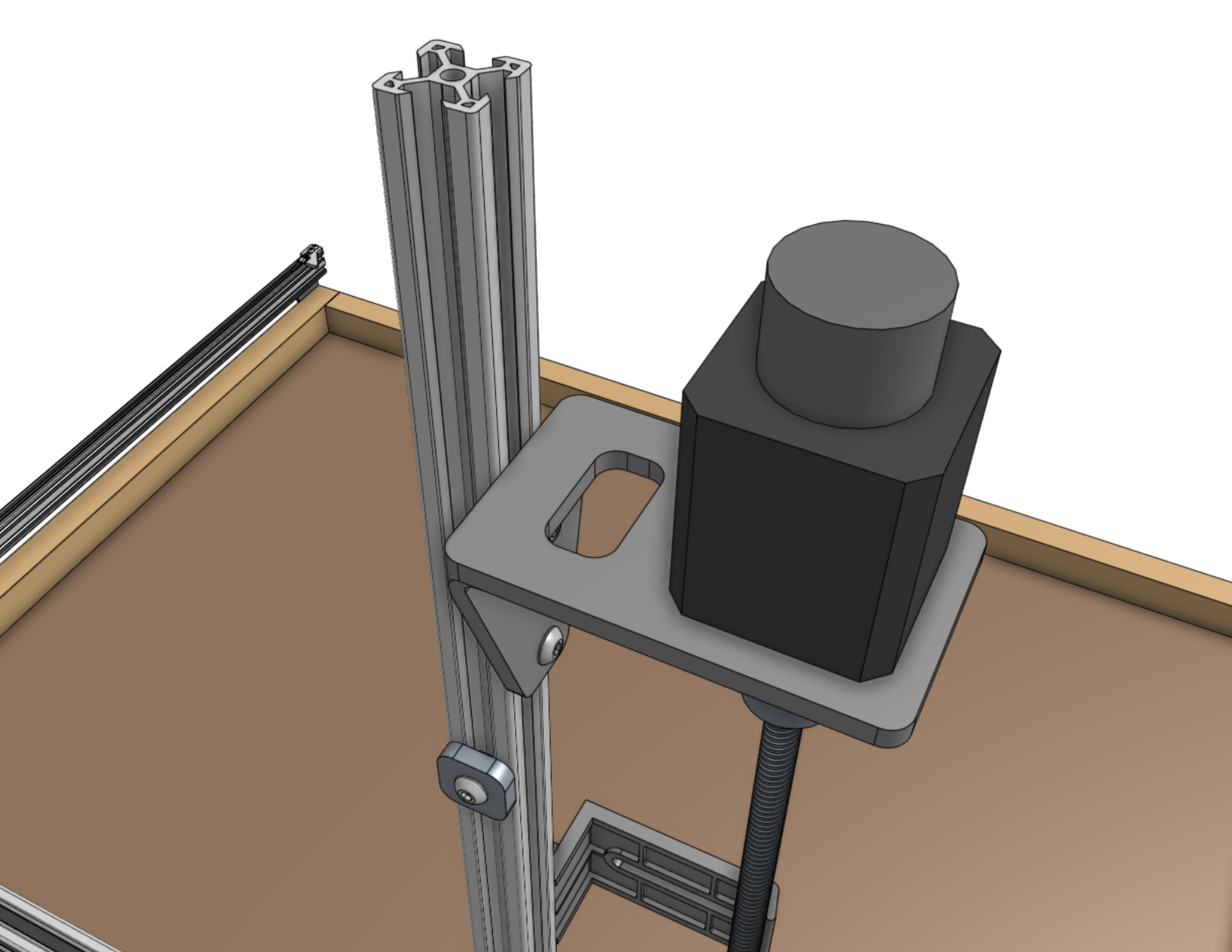

Step 2: Attach the motor mount to the Z-axis extrusion

Handle with care

The aluminum extrusions may have sharp corners and edges.

Attach the z-axis motor mount to the z-axis extrusion using a 60mm nut bar and M5 x 10mm screws. The top face of the motor mount should be 80mm from the end of the extrusion.

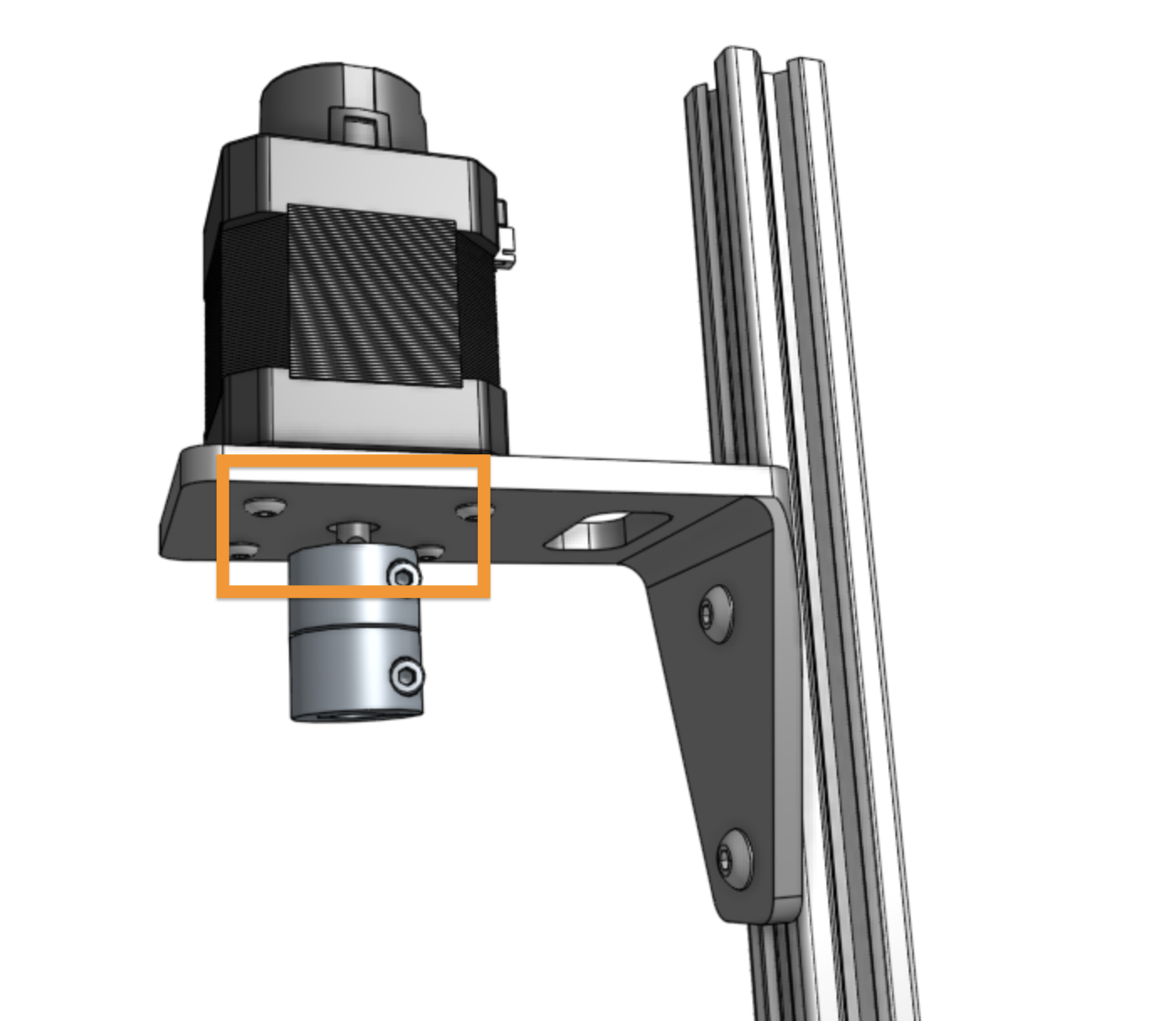

Step 3: Attach the shaft coupling

Slide the 5mm to 8mm shaft coupling onto the motor shaft and tighten the top screw with the 2.5mm hex key.

Mind the gap

Make sure there is a small gap (about 2mm) between the shaft coupling and the z-axis motor mount. You might use a credit card to help provide the correct spacing needed.

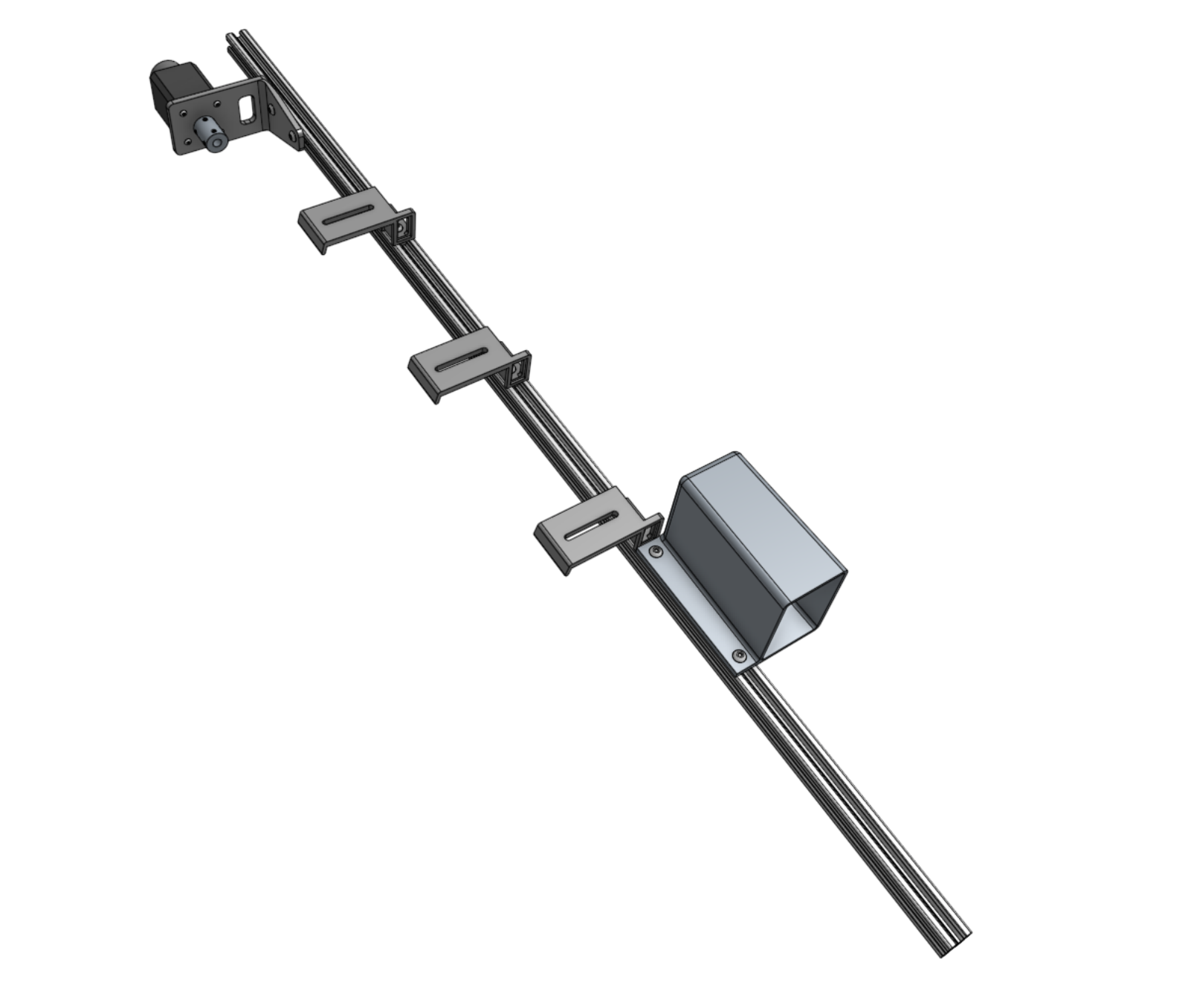

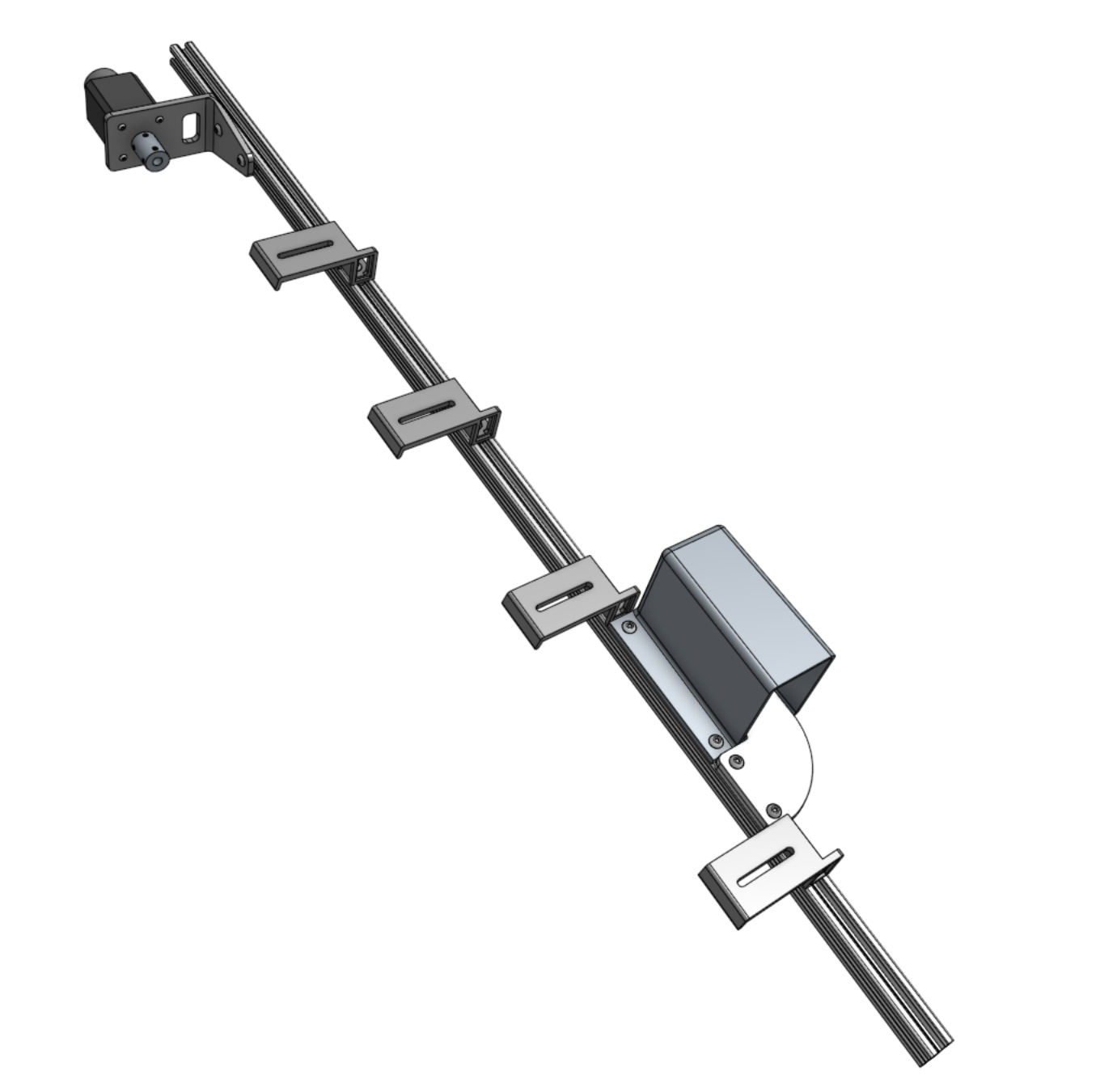

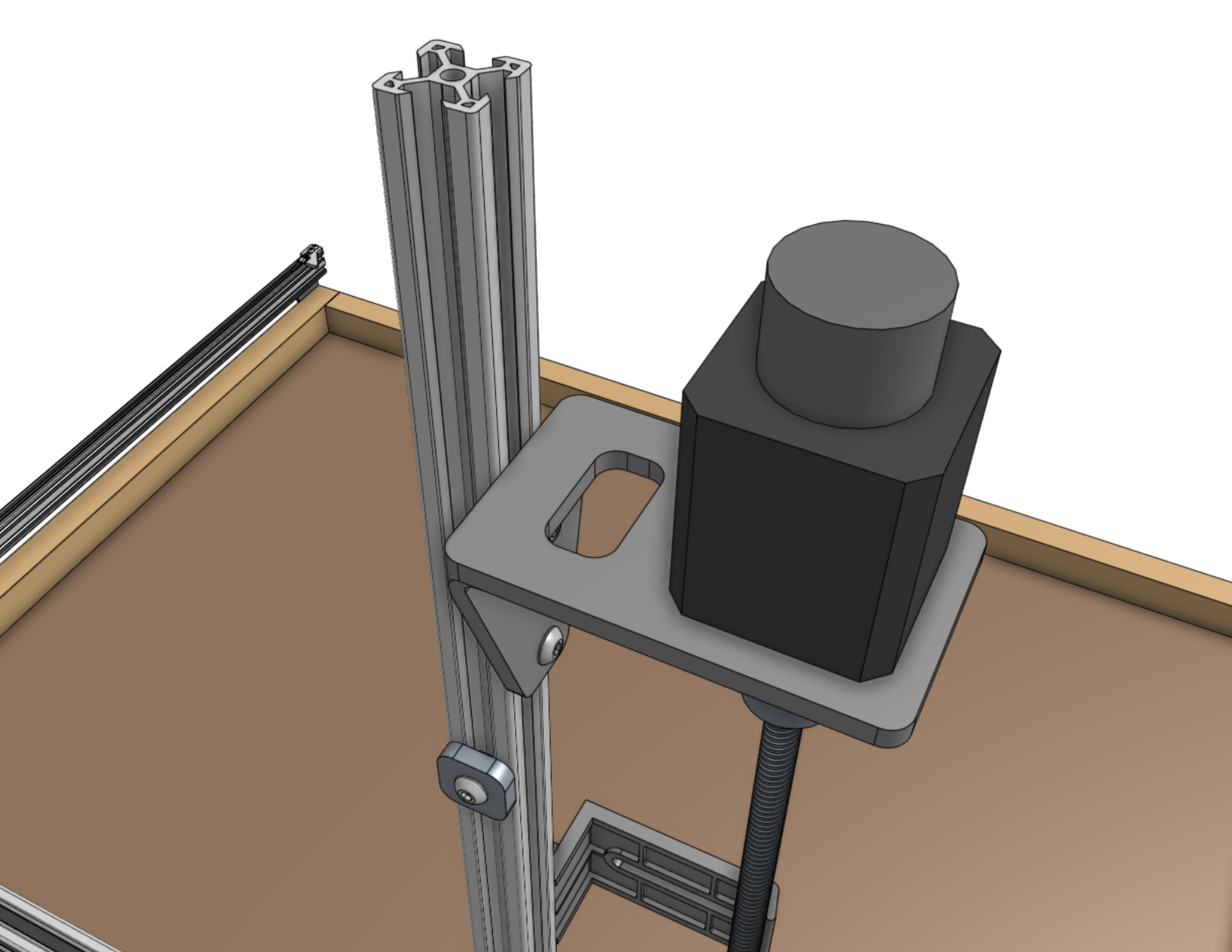

Step 4: Attach three cable carrier supports

Attach three 60mm vertical cable carrier supports to the z-axis extrusion using 40mm nut bars and M5 x 10mm screws. Space the supports along the extrusion as shown.

Step 5: Attach the vacuum pump cover

Attach the vacuum pump cover to the z-axis extrusion using two M5 drop-in tee nuts and M5 x 10mm screws. The cover should be butted up against the lowest cable carrier support.

Step 6: Attach the vacuum pump

Fasten the vacuum pump to the vacuum pump mount using two 200mm zip ties. Then attach the vacuum pump mount to the z-axis extrusion using a 60mm nut bar and two M5 x 16mm screws. The mount should be butted up against the vacuum pump cover.

Step 7: Attach one more cable carrier support

Attach one more 60mm vertical cable carrier support using a 40mm nut bar and two M5 x 10mm screws. The support should be butted up against the vacuum pump mount.

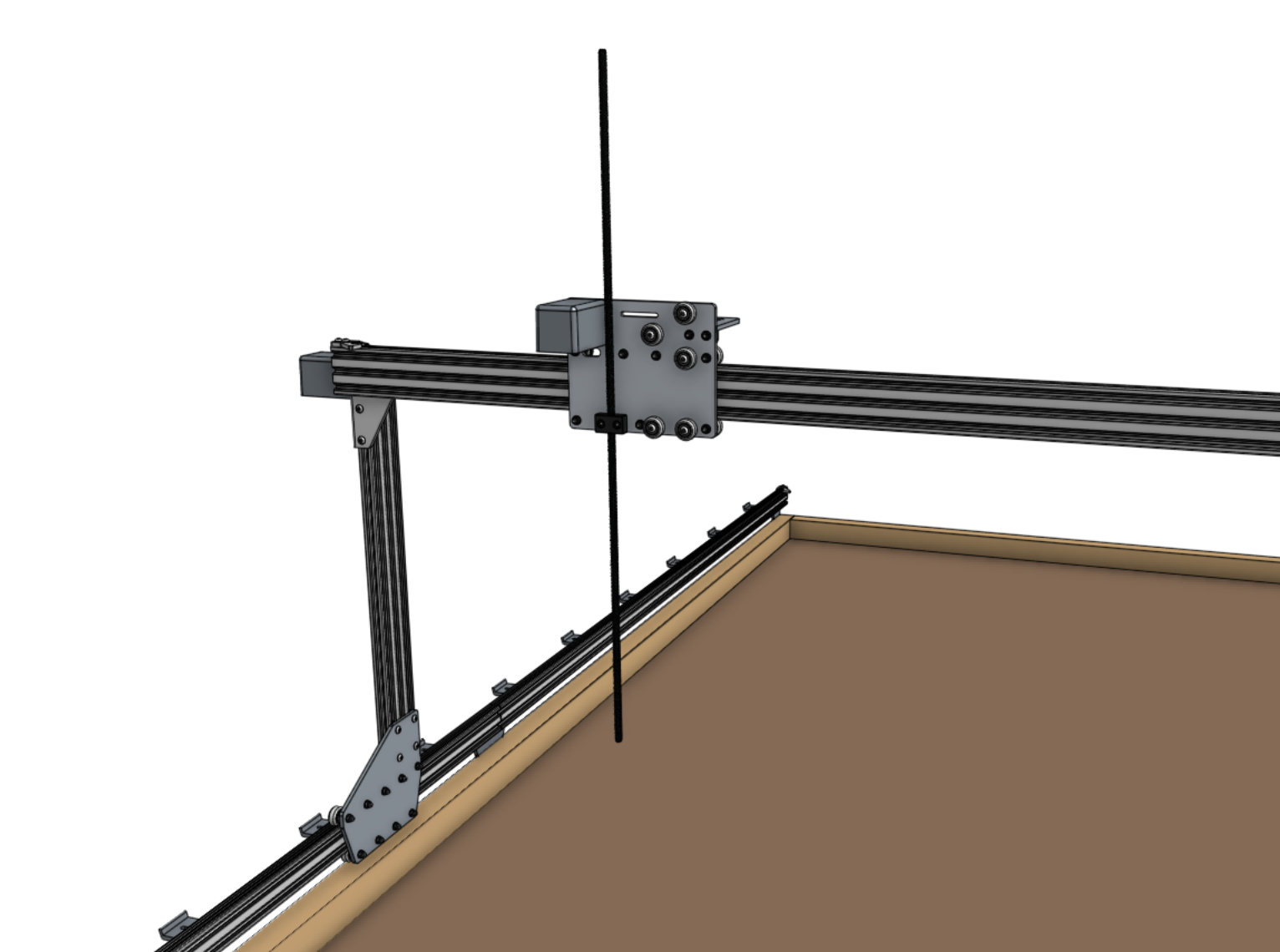

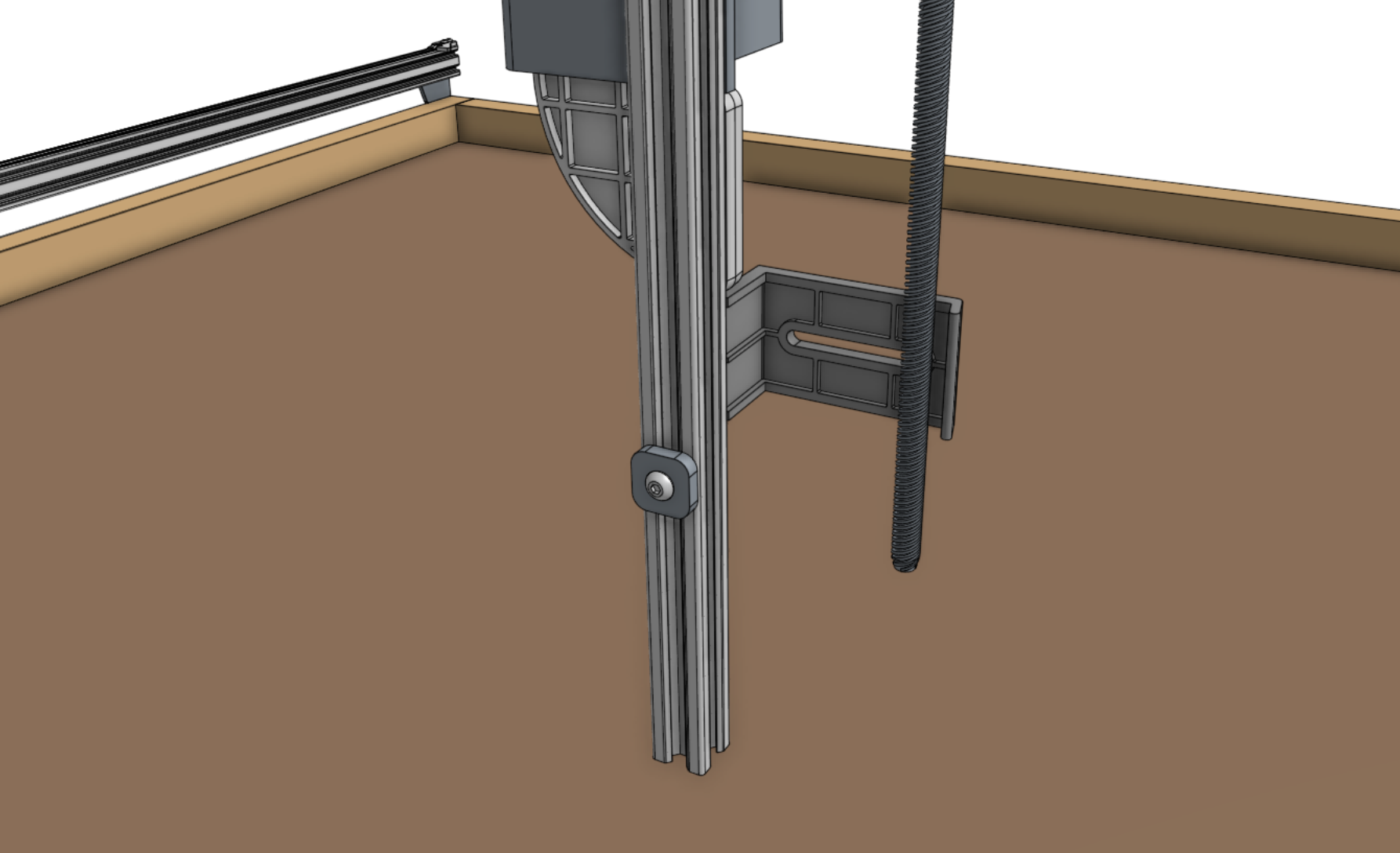

Step 8: Attach the z-axis to the cross-slide

Screw the leadscrew halfway into the leadscrew block.

Slide the z-axis extrusion through the v-wheels on the cross-slide until the leadscrew inserts into the 5mm to 8mm shaft coupling. Then tighten the coupling’s lower screw with the 2.5mm hex key.

Adjust the eccentric spacers as needed

In order to slide the z-axis through the v-wheels you will need to adjust the eccentric spacers of the three v-wheels on the right side of the cross-slide. Refer to the eccentric spacer adjustment reference guide for how to do this.

Step 9: Install the hardstops

Attach the z-axis hardstops onto the backside of the z-axis extrusion approximately 200mm from the top of the extrusion and 100mm from the bottom of the extrusion using M5 x 10mm screws and tee nuts. Later, you can quickly adjust these to physically prevent FarmBot from moving too low or too hight within its working space.

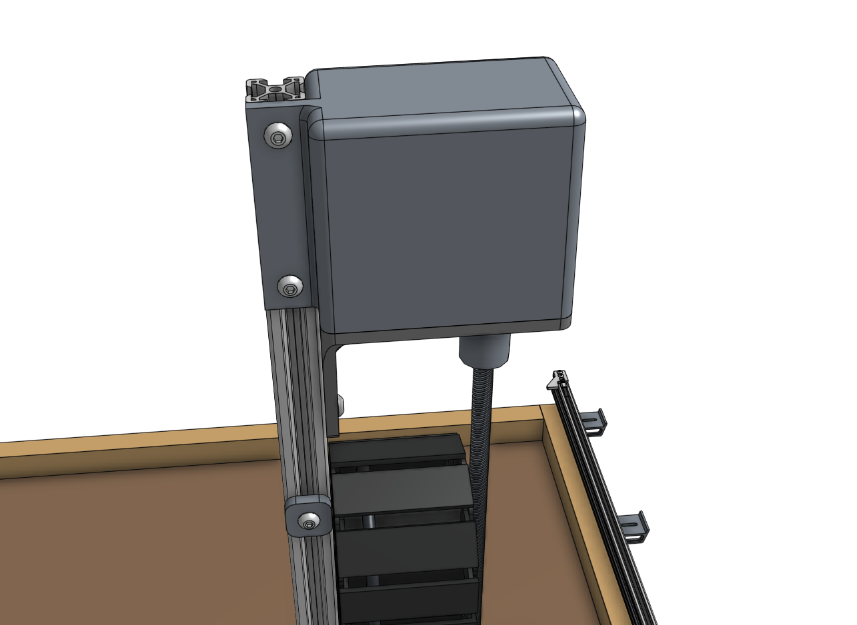

Step 10: Add the vertical motor housing (optional)

If you plan on stopping assembly after this page, it is recommended to attach the 80mm vertical motor housing to the z-axis extrusion using M5 x 10mm screws and tee nuts now. This will protect the motor from rain and other hazards until you resume assembly at a later point. Once you resume assembly, you will need to remove the housing.

If you do not plan on stopping the assembly process now, you can skip this step and install the housing after the z motor and encoder cables have been connected in the next step.