Construct the Gantry Structure

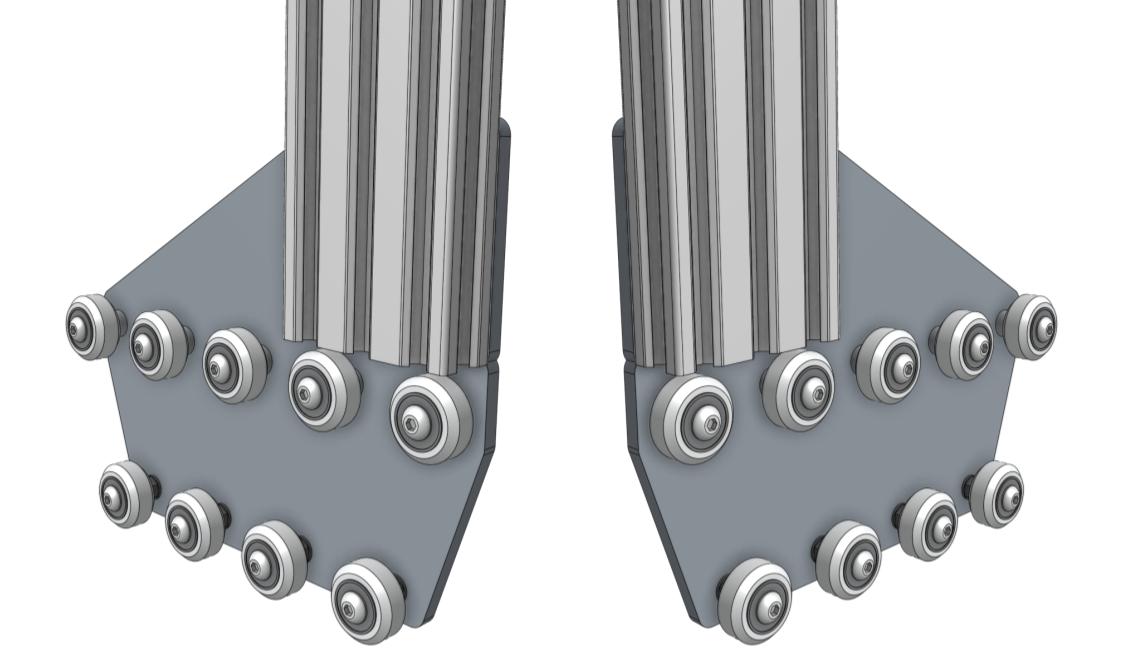

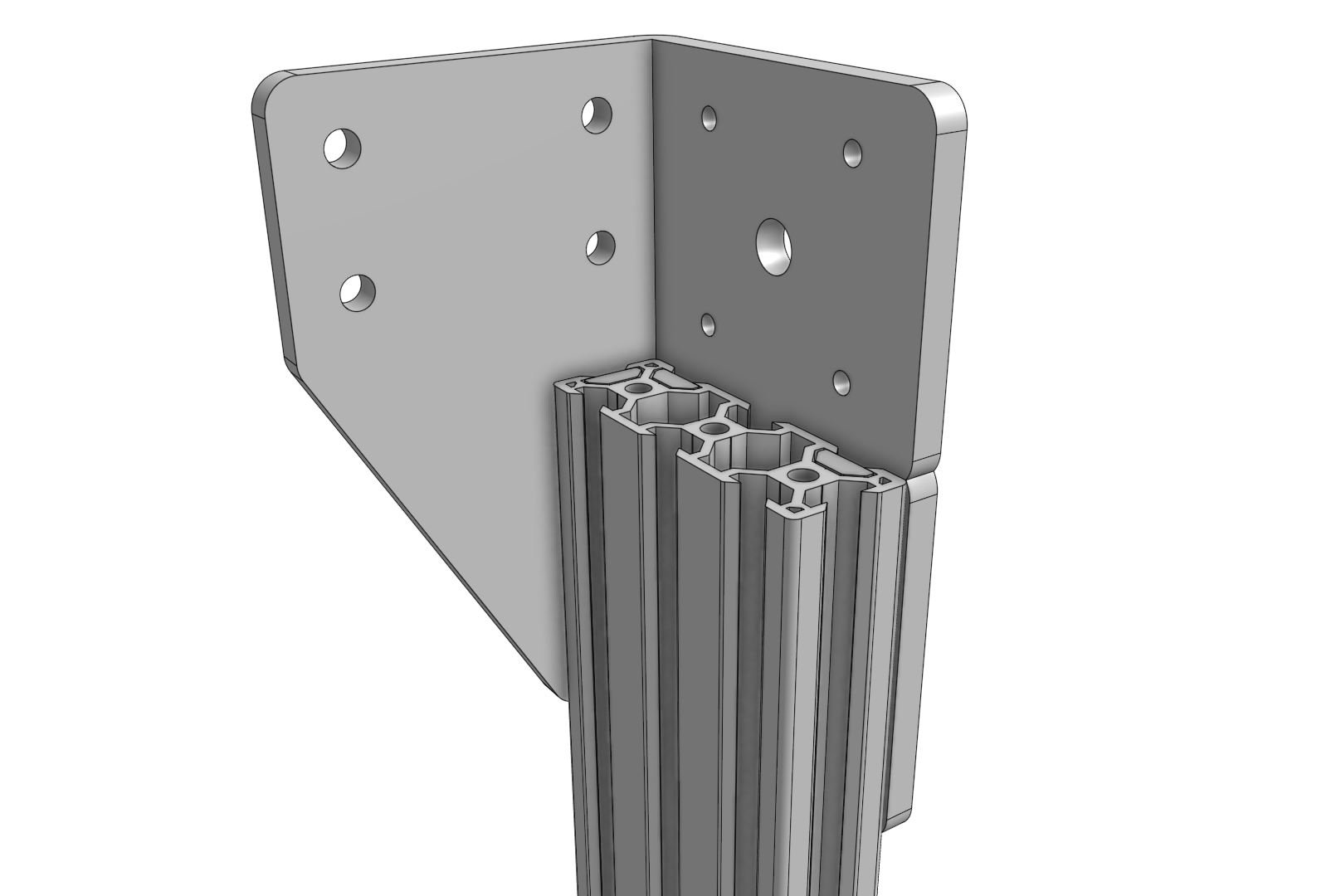

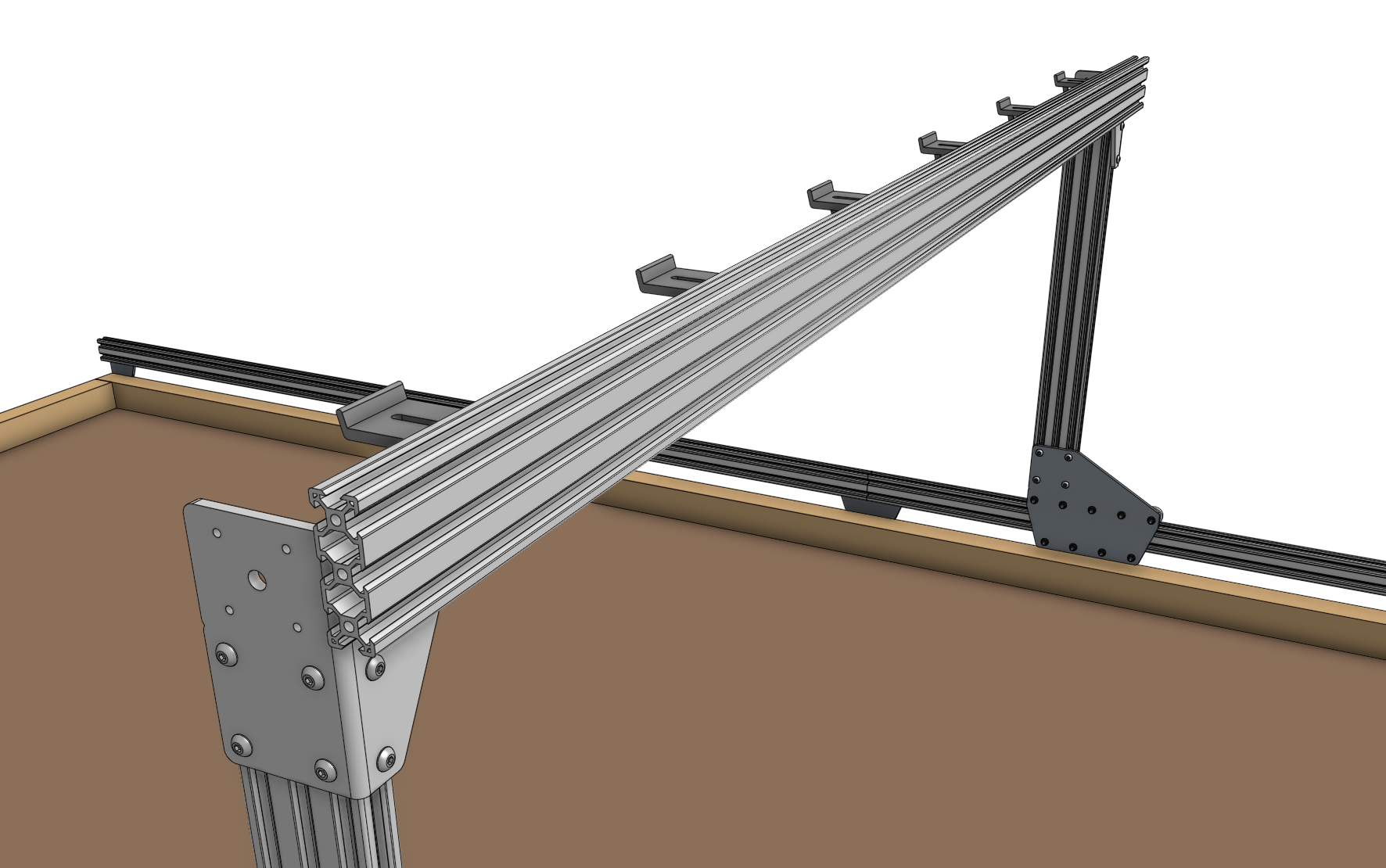

Step 1: Attach the plates to the columns

Slide a gantry column onto the gantry wheel plate assembly. The extrusion should reside on the same side of the plate as the V-wheels and the end of the extrusion should be aligned with the notch in the plate. Tighten the M5 x 10mm screws using the 3mm hex driver.

Repeat for the second gantry wheel plate and aluminum extrusion.

Handle with care

The aluminum extrusions may have sharp corners and edges.

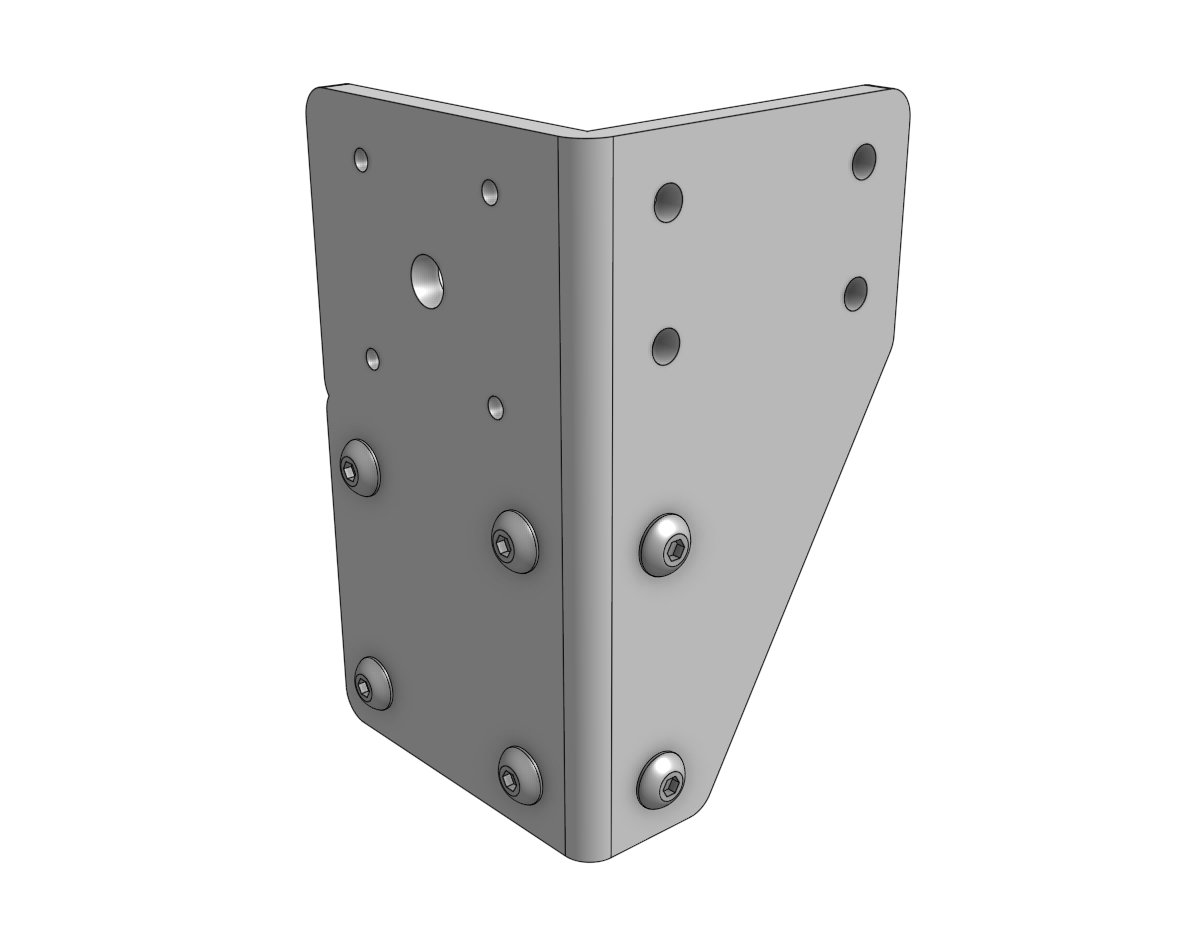

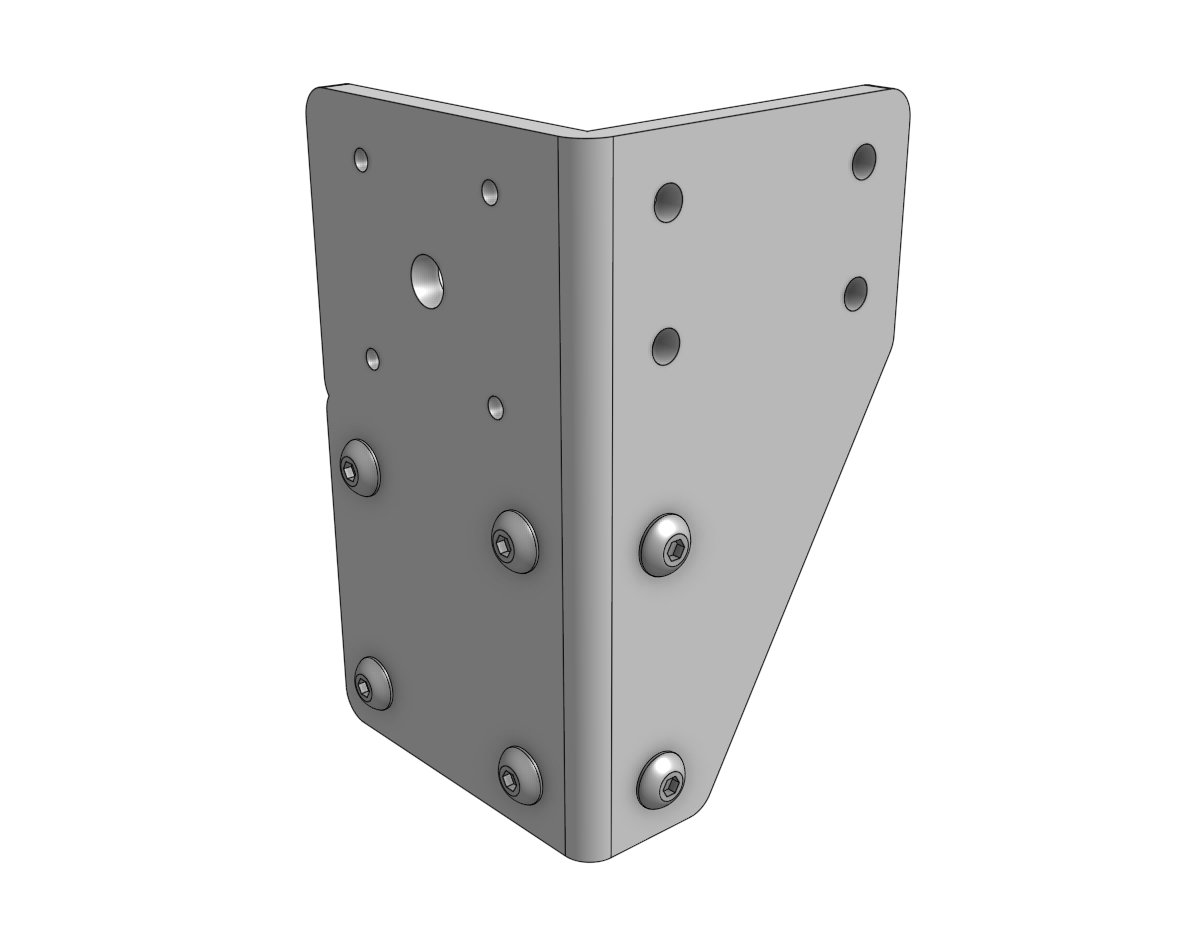

Step 2: Attach the gantry corner brackets

Lightly attach three 60mm nut bars to each gantry corner bracket using M5 x 10mm screws. Then slide the corner brackets onto the gantry column/plate assemblies. The top of the extrusions should line up with the notches in the corner brackets.

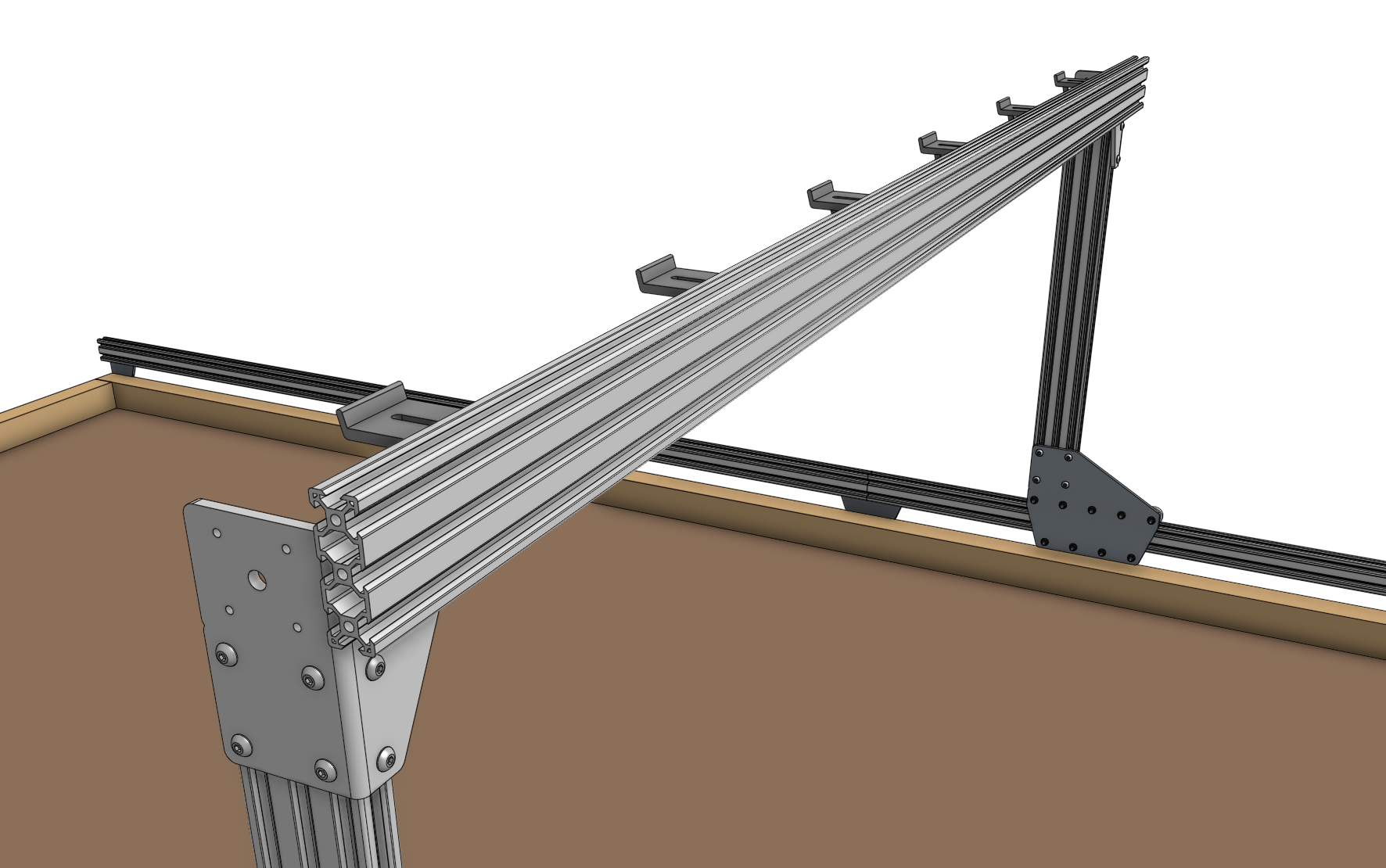

Orientation is key

Pay special attention to the orientation of the brackets, extrusions, and wheel plates in the images below. You should end up with two assemblies that are mirror images of each other.

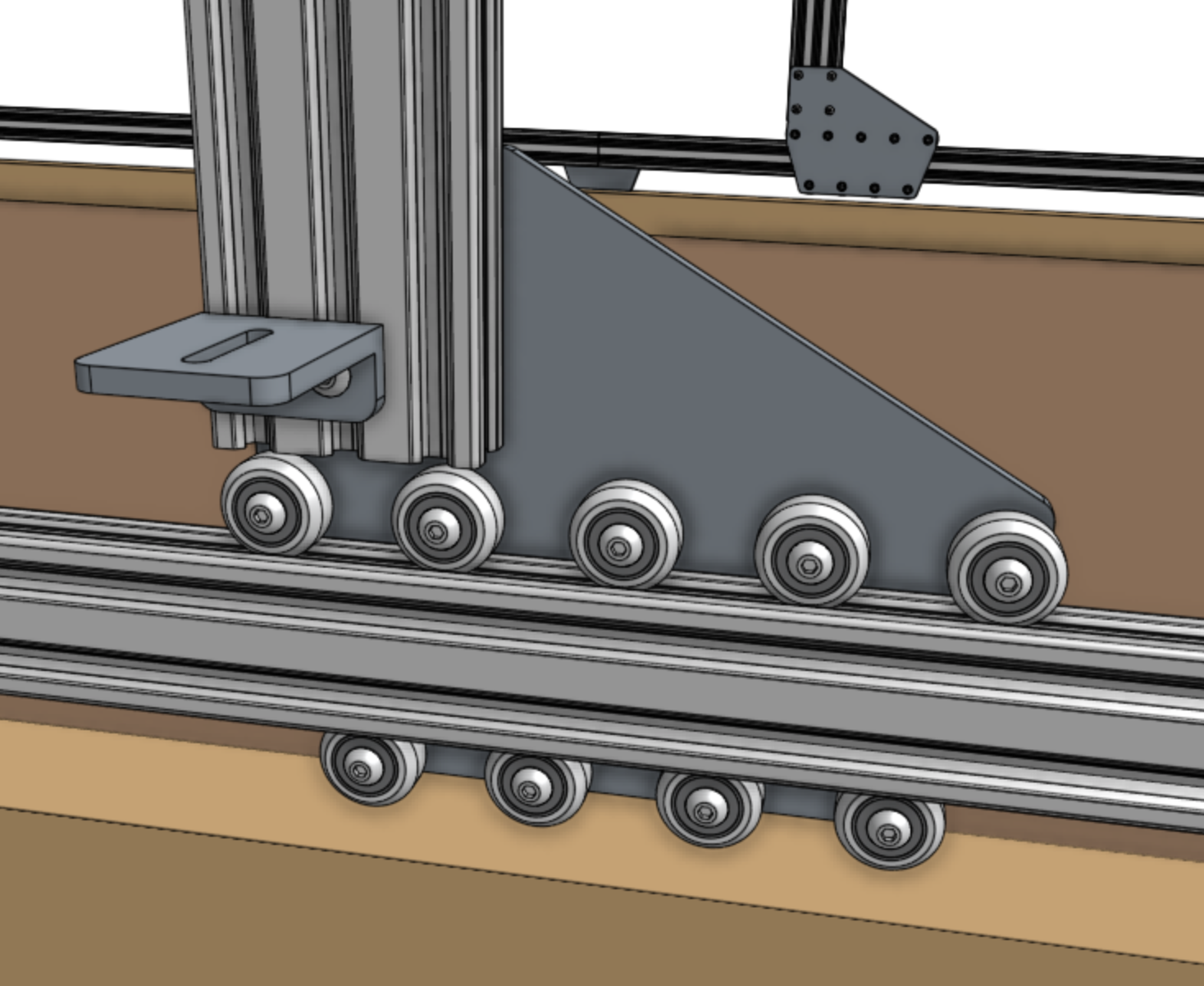

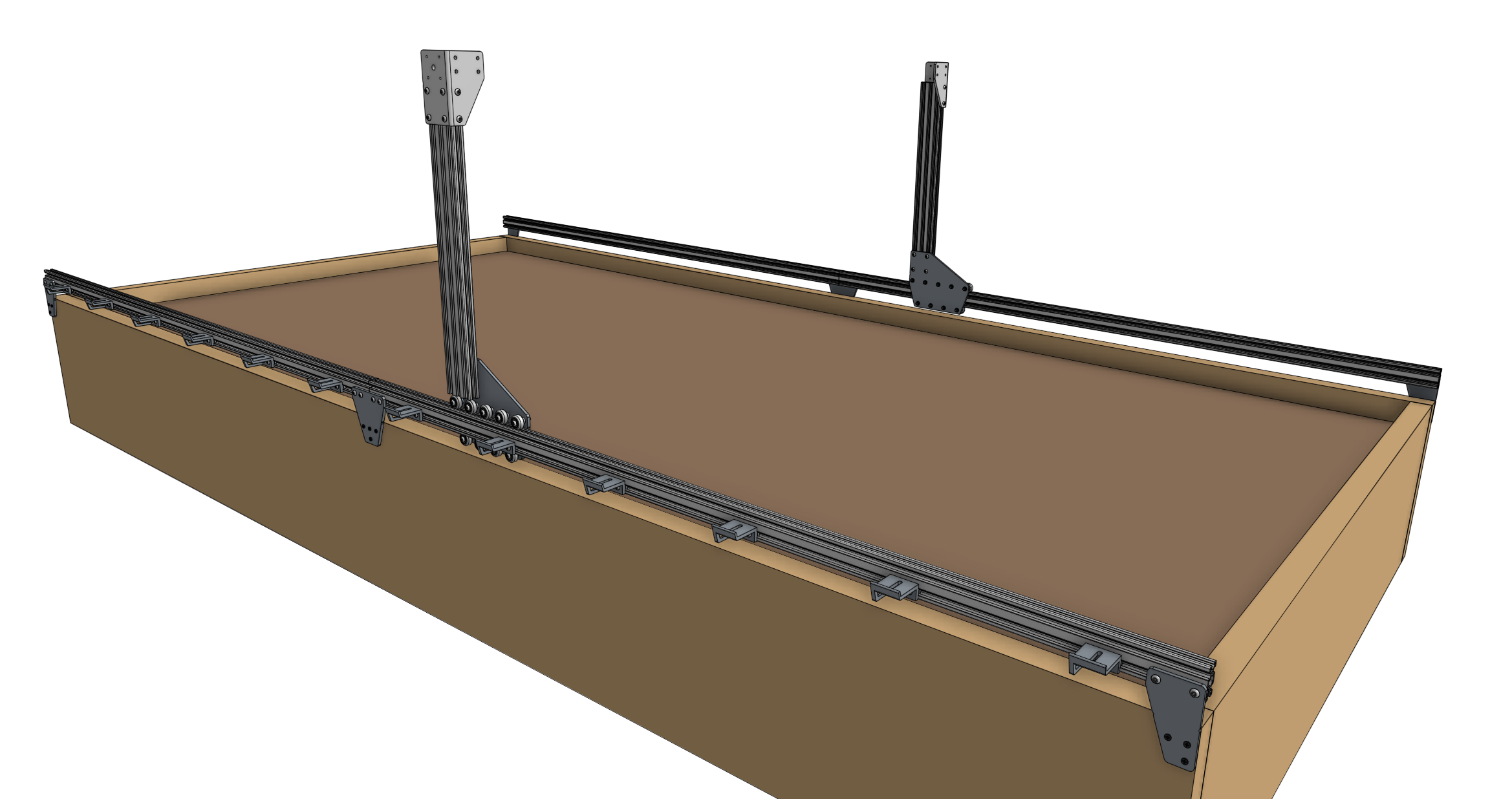

Step 3: Slide onto the tracks

Adjust the eccentric spacers first

This step is assuming that you have already adjusted the eccentric spacers according to the eccentric spacer adjustment guide.

Slide the gantry columns onto the tracks. The direction that the wheel plates extend from the column is towards the front of FarmBot. Ensure that the cable carrier supports (mounted to the tracks) are on the left side of the FarmBot.

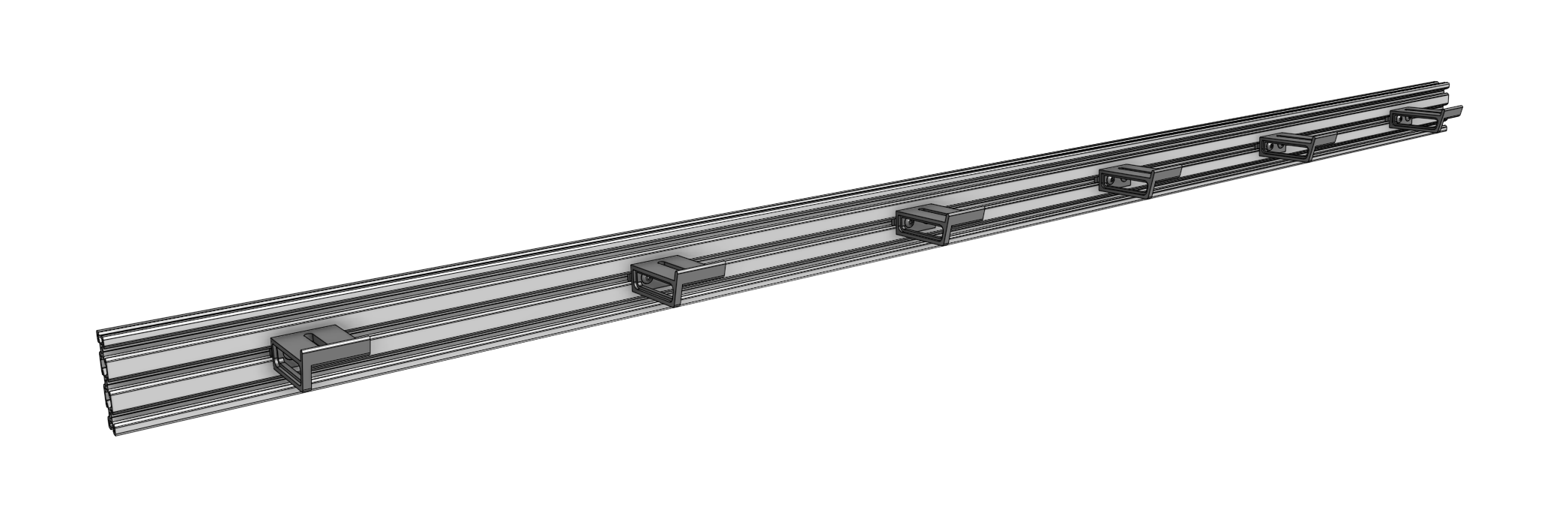

Step 4: Assemble the main beam

This step applies to XL and MAX kits only

If you have a standard sized Genesis kit (1.5m wide), proceed to the next step.

Place both gantry main beams on a flat surface such as a table or patio. Using two 140mm nut bars and eight M5 x 10mm screws, attach the gantry joining bracket to the lower two slots of both extrusions. The notch in the middle of the bracket should be aligned with the joint between the two extrusions.

Your kit may not include 140mm nut bars

If your kit was shipped before November of 2020, it does not include 140mm nut bars. Instead, use four 60mm nut bars to attach each extrusion to the gantry joining bracket.

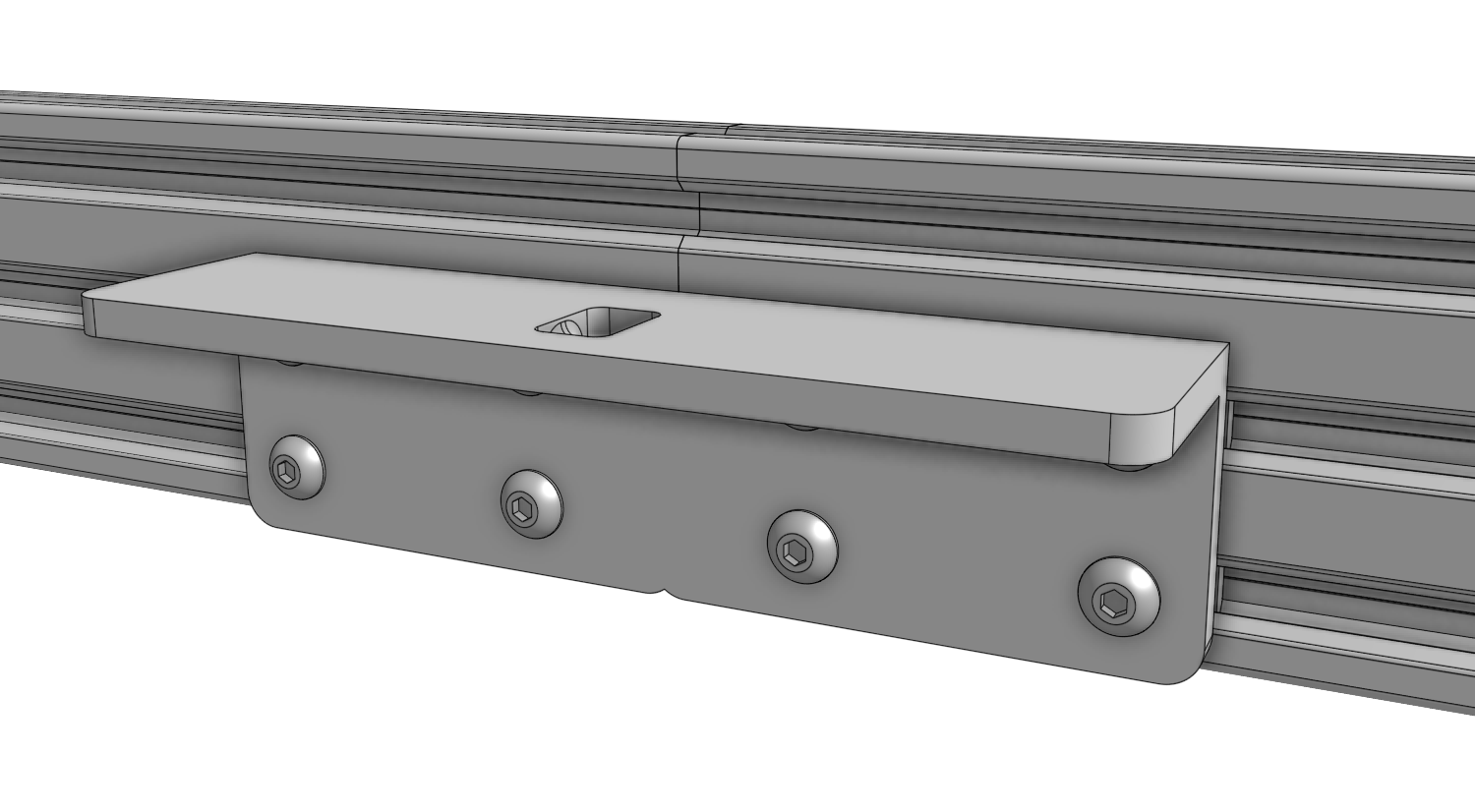

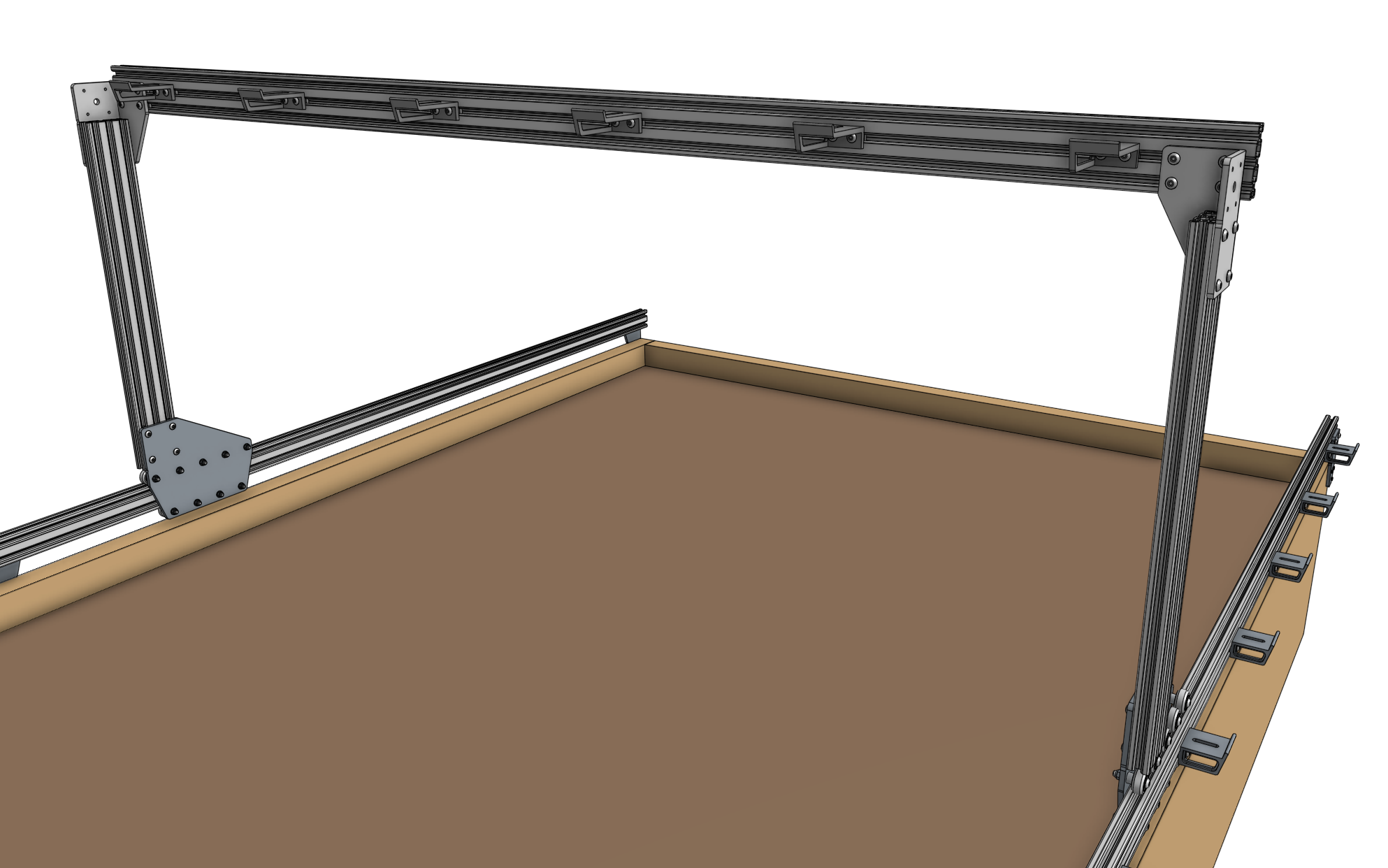

Step 5: Attach the cable carrier supports

Using M5 x 10mm screws and 40mm nut bars, attach six 60mm horizontal cable carrier supports to the middle slot of the gantry main beam extrusion. For genesis kits, there is only one main beam extrusion, so only six supports will be used.

For Genesis XL and MAX kits, there are two main beam extrusions, so 12 supports will be used, and they should be positioned on the same side of the extrusions as the gantry joining bracket.

Step 6: Attach the main beam

Grab a friend

The next step requires an additional person to complete.

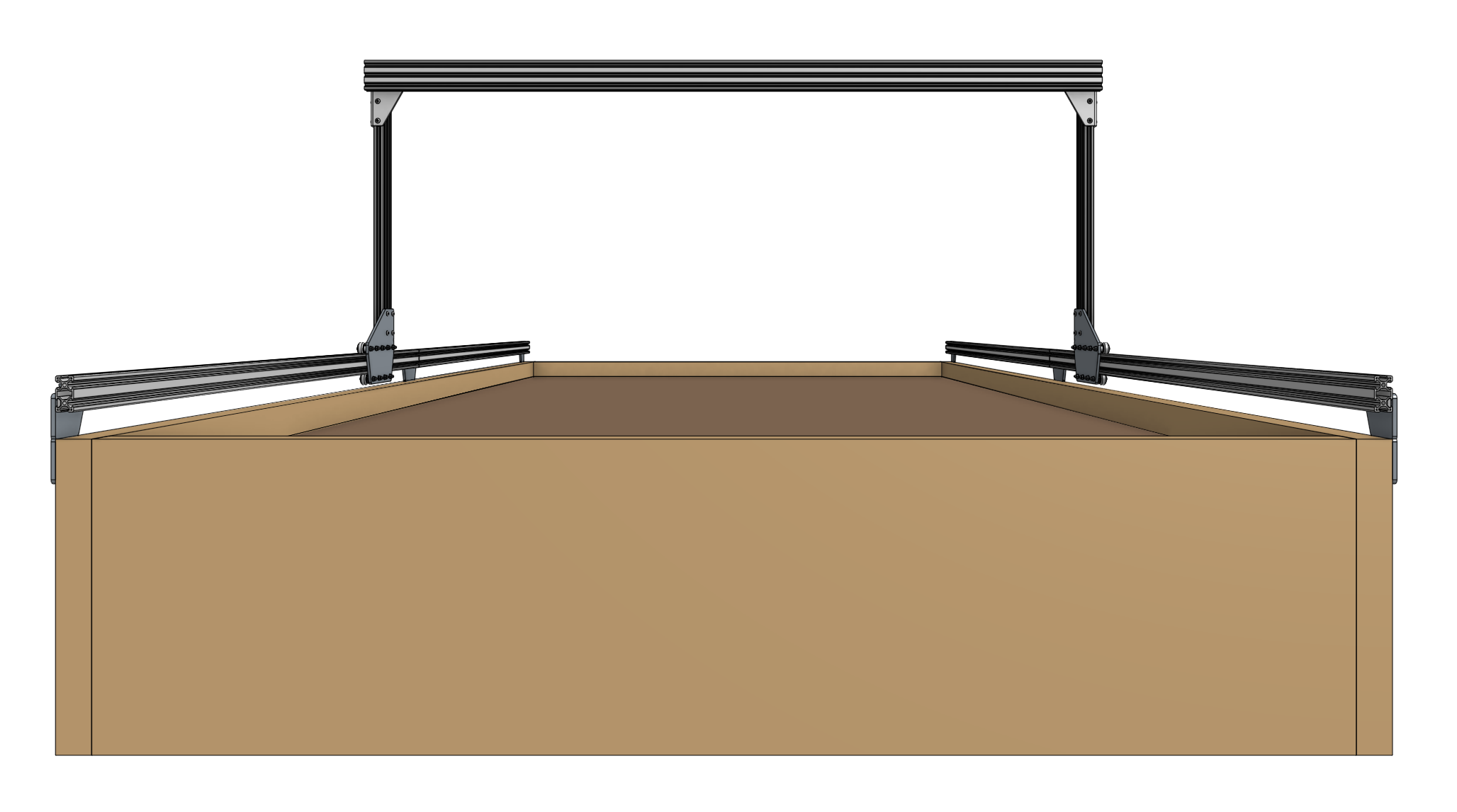

Lift up the gantry main beam and position it onto the front of the gantry corner brackets. The cable carrier supports should be on the same side of the main beam as the gantry corner brackets. Secure the main beam in place using four 60mm nut bars and M5 x 10mm screws. The nut bars should be positioned in the lower two extrusion slots of the main beam such that the top face of the main beam is 20mm above the top edges of the gantry corner brackets.

Ensure that the gantry columns are vertical and form a 90 degree angle with the main beam. Then tighten the M5 x 10mm screws. Depending on the spacing of your tracks, the gantry main beam may extend beyond the corner brackets. This is ok.

This image is from the front of FarmBot

Step 7: Attach the x-axis cable carrier mount

Use two M5 x 10mm screws and drop-in tee nuts to attach the aluminum 50mm cable carrier mount to the bottom of the left gantry column.