Wire up the UTM

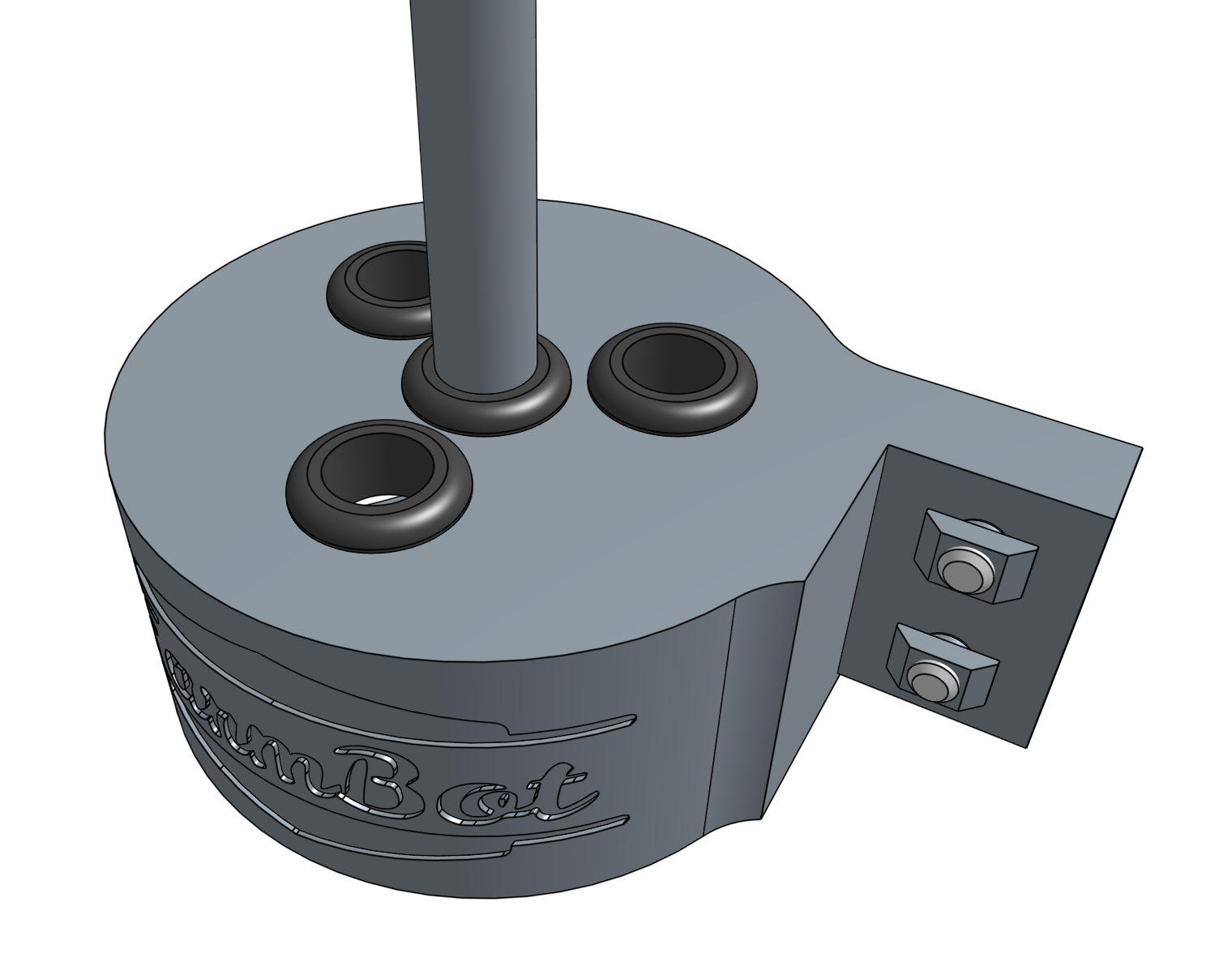

Step 1: Feed the UTM cable through the UTM cover

Push the end of the UTM cable without a connector through the center grommet in the UTM cover so that the outer black rubber of the cable extends about 5cm beneath the cover.

Be gentle

It may be difficult to do this because of the friction and tight seal created between the grommet and the cable. Be gentle and take your time. Some soapy water can facilitate the cable to slide through more easily, and will dry up within a day.

The individual wires of the UTM cable are color coded. Fan out the wires in preparation for connection.

Step 2: Feed the tubing through the UTM cover

Push the vacuum tube (the short tube) through the grommet nearest the FarmBot logo on the UTM cover so that there is about 10cm of tubing beneath the cover.

Push the water tube (the long tube) through the grommet nearest the UTM cover mounting flange so that there is about 10cm of tubing beneath the cover.

Insert the UTM cover plug into the remaining grommet in the UTM cover. This port is available for you to expand the functionality of your FarmBot if you desire.

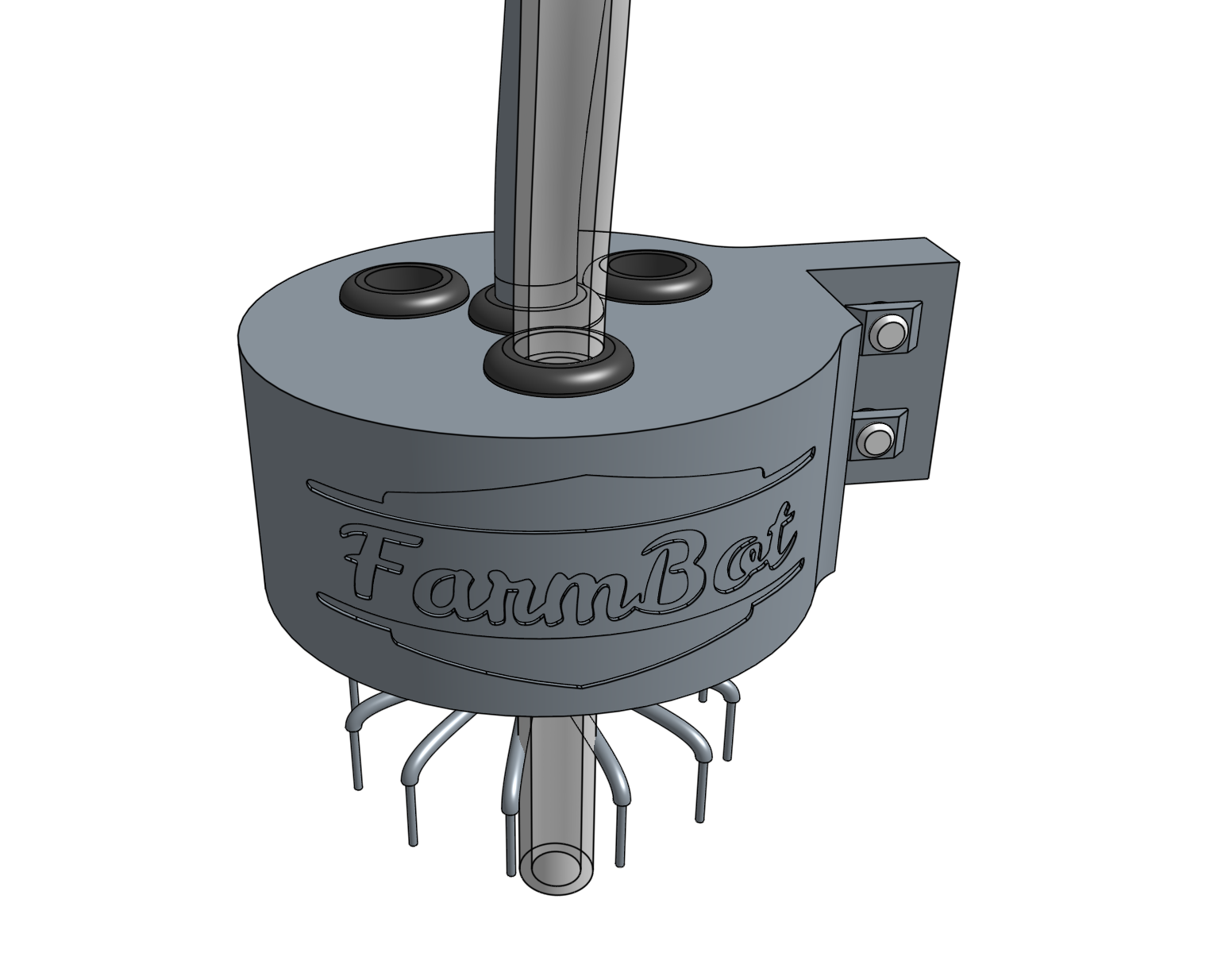

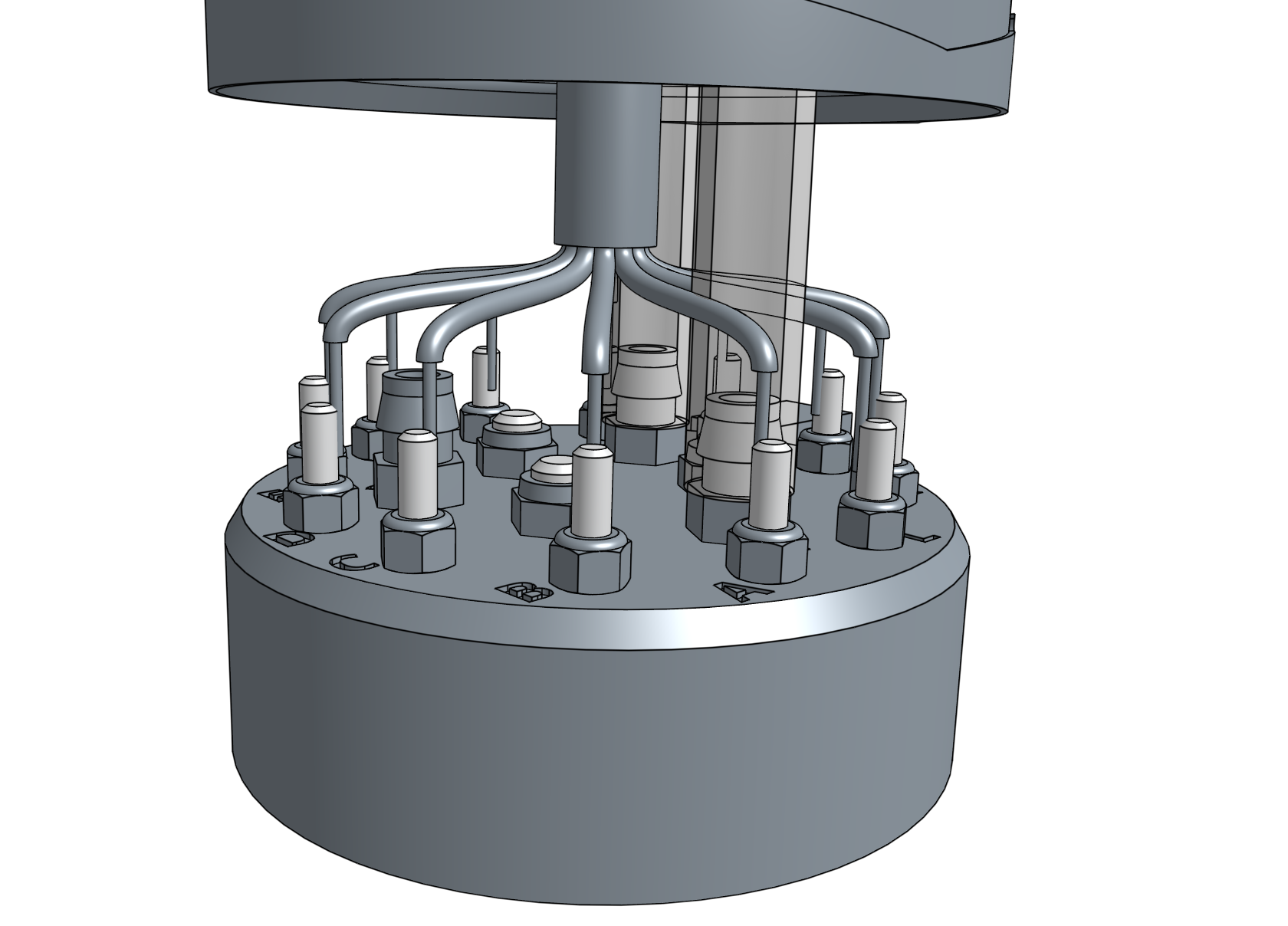

Step 3: Attach the tubes

Slide the vacuum tube and water tube onto the corresponding barbs on the UTM.

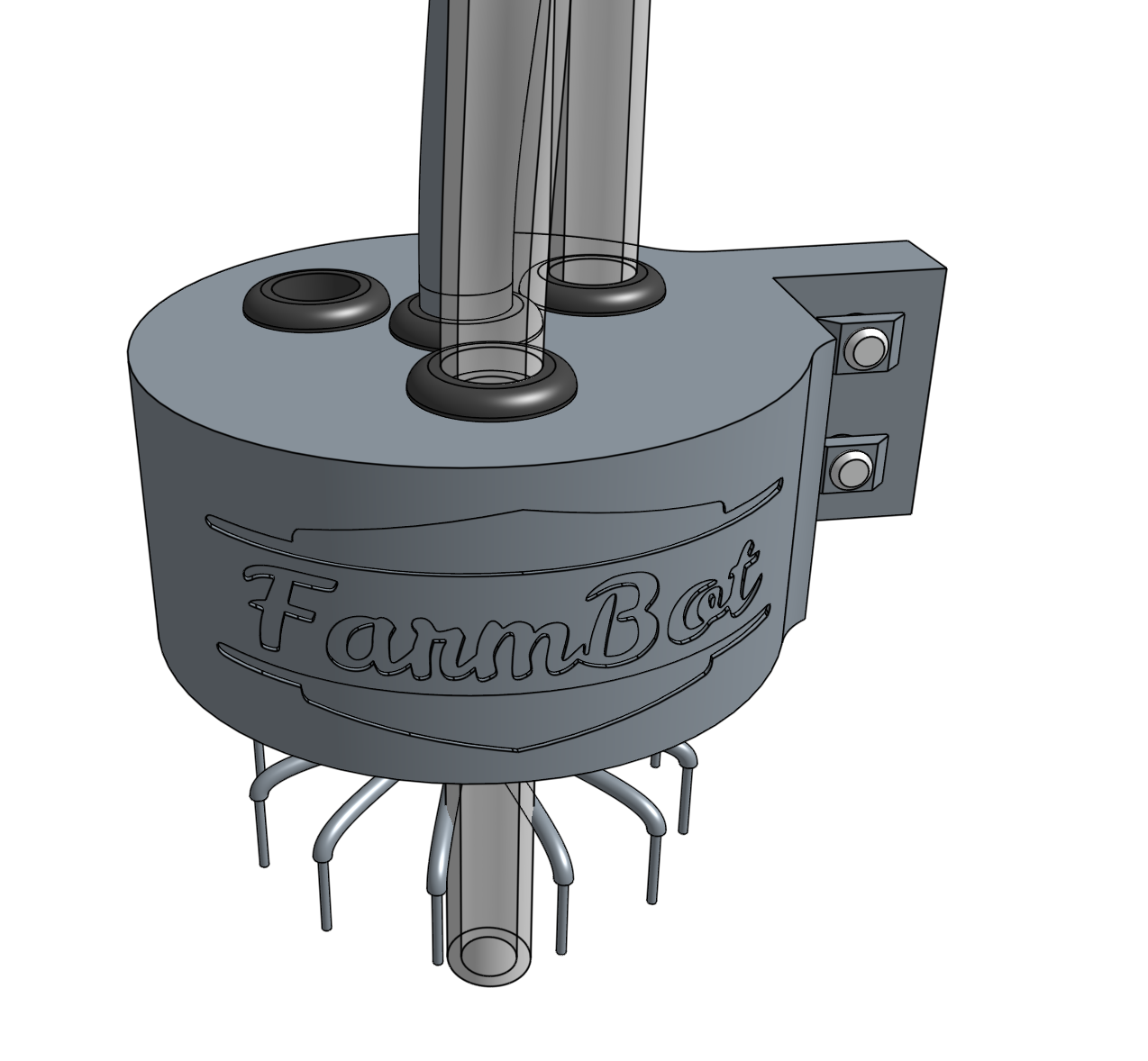

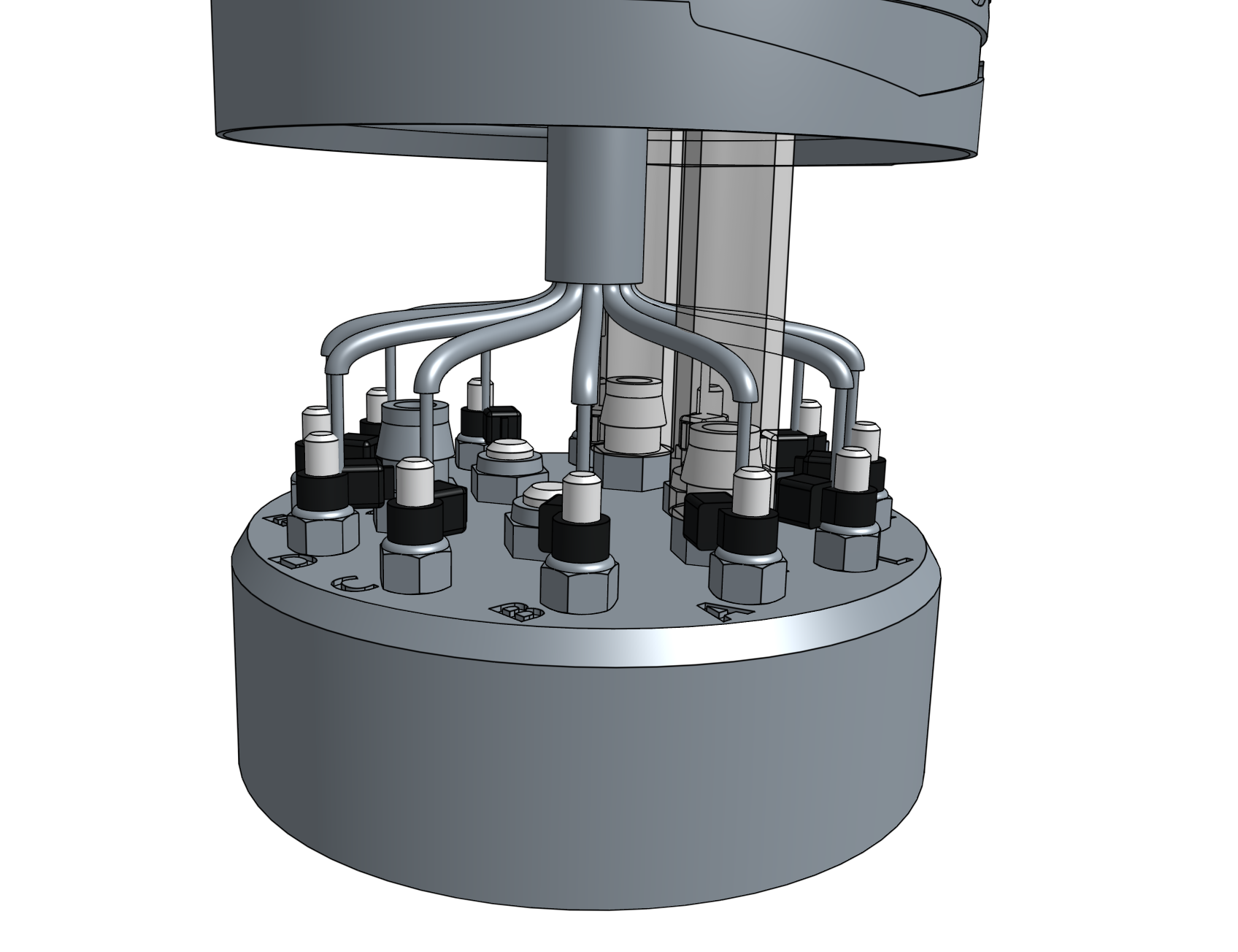

Step 4: Wire up the UTM

Use a 63.7mm zip-tie to secure each UTM cable wire to the M3 screw on top of the UTM according to the pin mapping table below. The wire strands must make good contact with the screw threads.

Pin mapping

Room for expansion

Only four of the 12 wires/UTM pins are currently mapped. This is because the currently available FarmBot tools only need these four pins to function, which means that the other eight pins are ready for you to map however you desire. Dreaming of a USB, I2C, or PWM based tool? Go right ahead and expand upon your FarmBot’s abilities with custom tools of your own!

| UTM Pin/UTM Wire | is connected to | and used for |

|---|---|---|

| A /red | +5V | Soil sensor |

| B /yellow | Ground (0V) | Ground |

| C /green | Pin D63 - Digital-In | Tool verification |

| D /black | Pin D59 (A5) - Analog-In | Soil sensor and other analog signal tools |

| E /white | Your choice | Anything you want |

| F /brown | Your choice | Anything you want |

| G /blue | Your choice | Anything you want |

| H /grey | Your choice | Anything you want |

| I /orange | Your choice | Anything you want |

| J /purple | Your choice | Anything you want |

| K /pink | Your choice | Anything you want |

| L /cyan | Your choice | Anything you want |

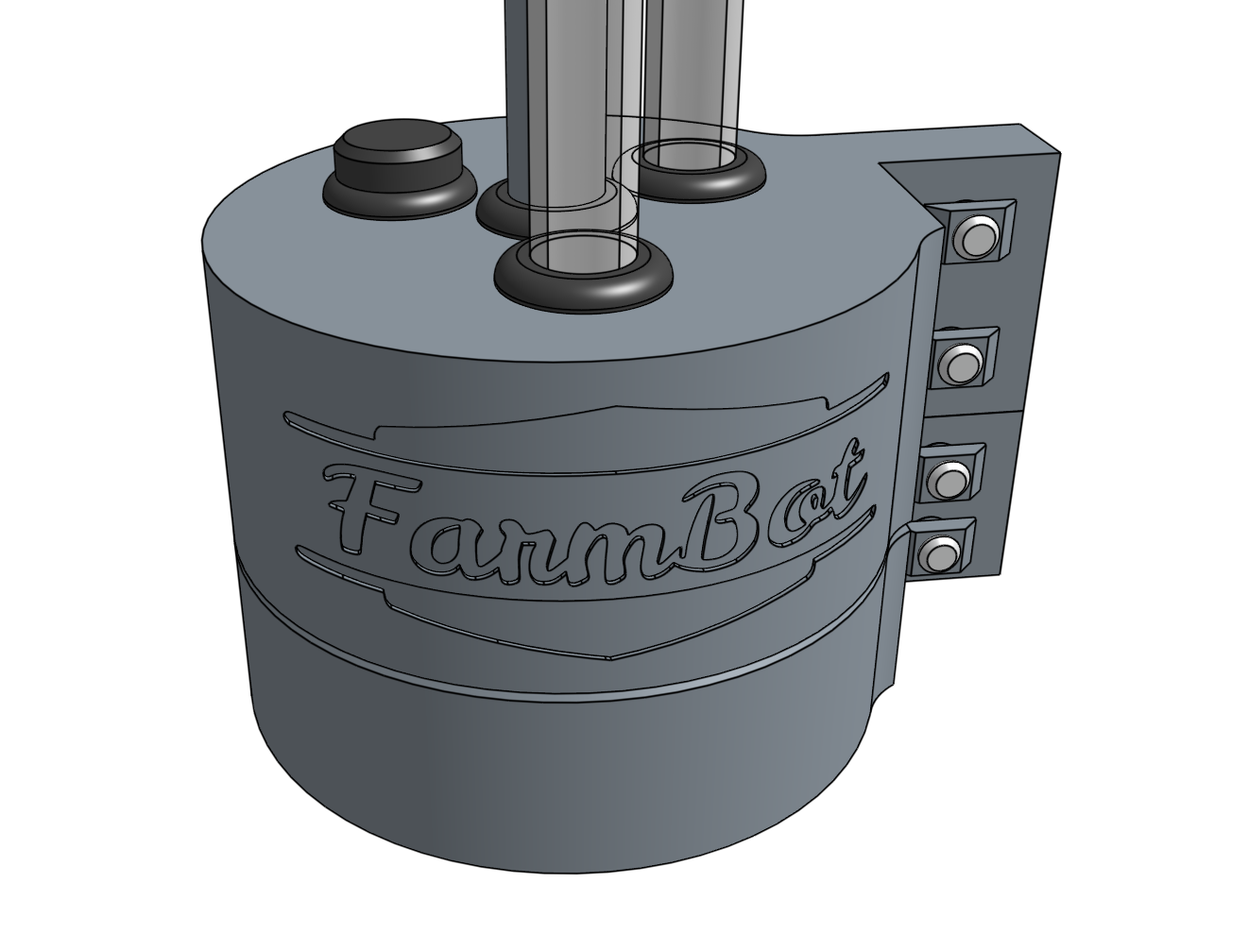

Step 5: Slide down the UTM cover

Slide the UTM cover down the tubes and cable until it sits flush against the top of the UTM. Ensure that no wires or tubes become disconnected and that there is sealing between the cable and the grommet.

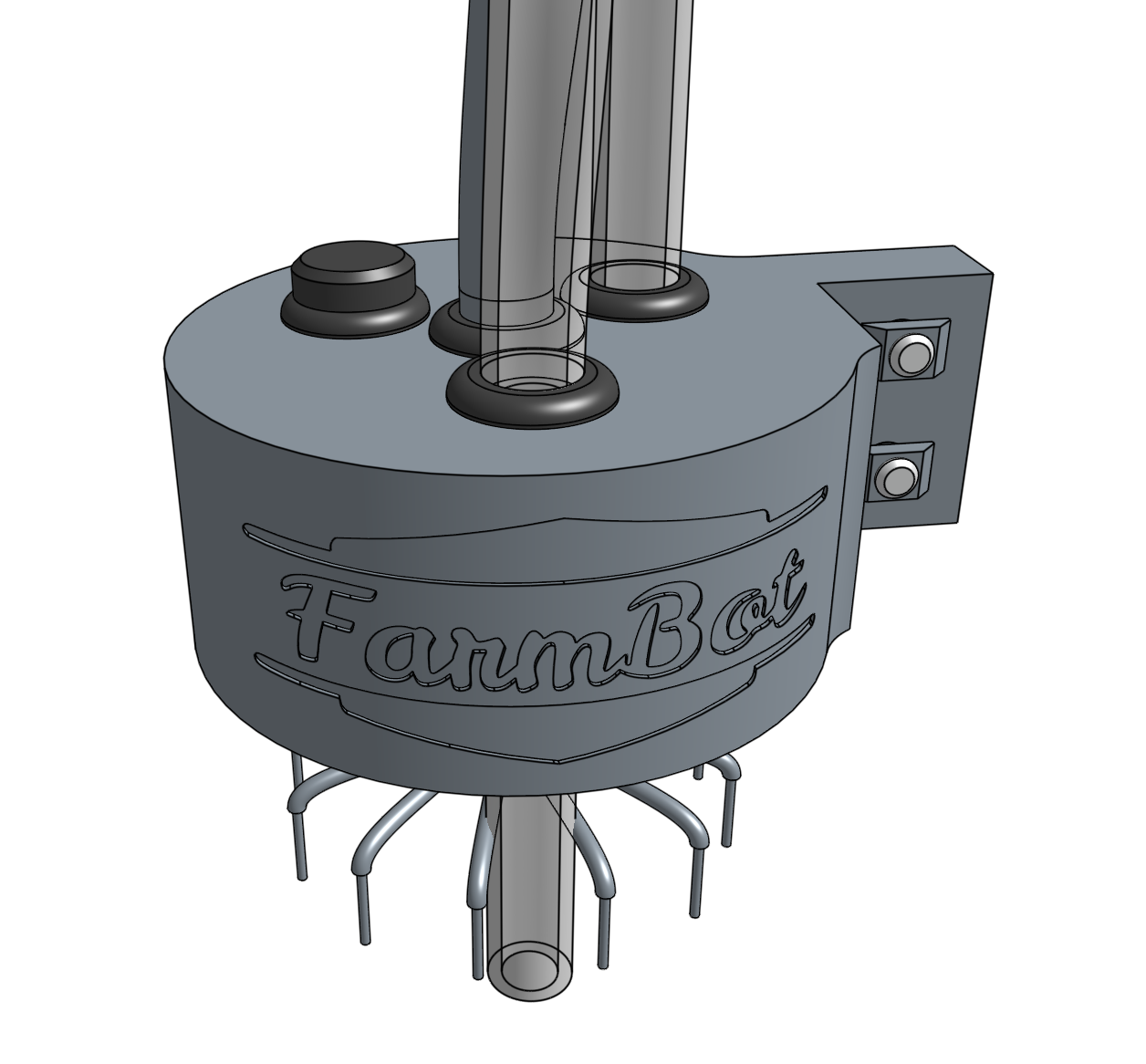

Step 6: Install the UTM and cover onto the Z-axis

Position the UTM cover and UTM onto the z-axis extrusion. The mounting flanges should be positioned on the backside of the extrusion. The bottom of the UTM should be flush with the bottom of the extrusion, and the bottom of the UTM cover should be flush with the top of the UTM. Tighten all four M5 screws with the 3mm hex driver.

Woo hoo!

You just finished the most tedious and arguably difficult part of building your FarmBot. Take a deep breath, do a stretch, and grab a snack - you deserve it!