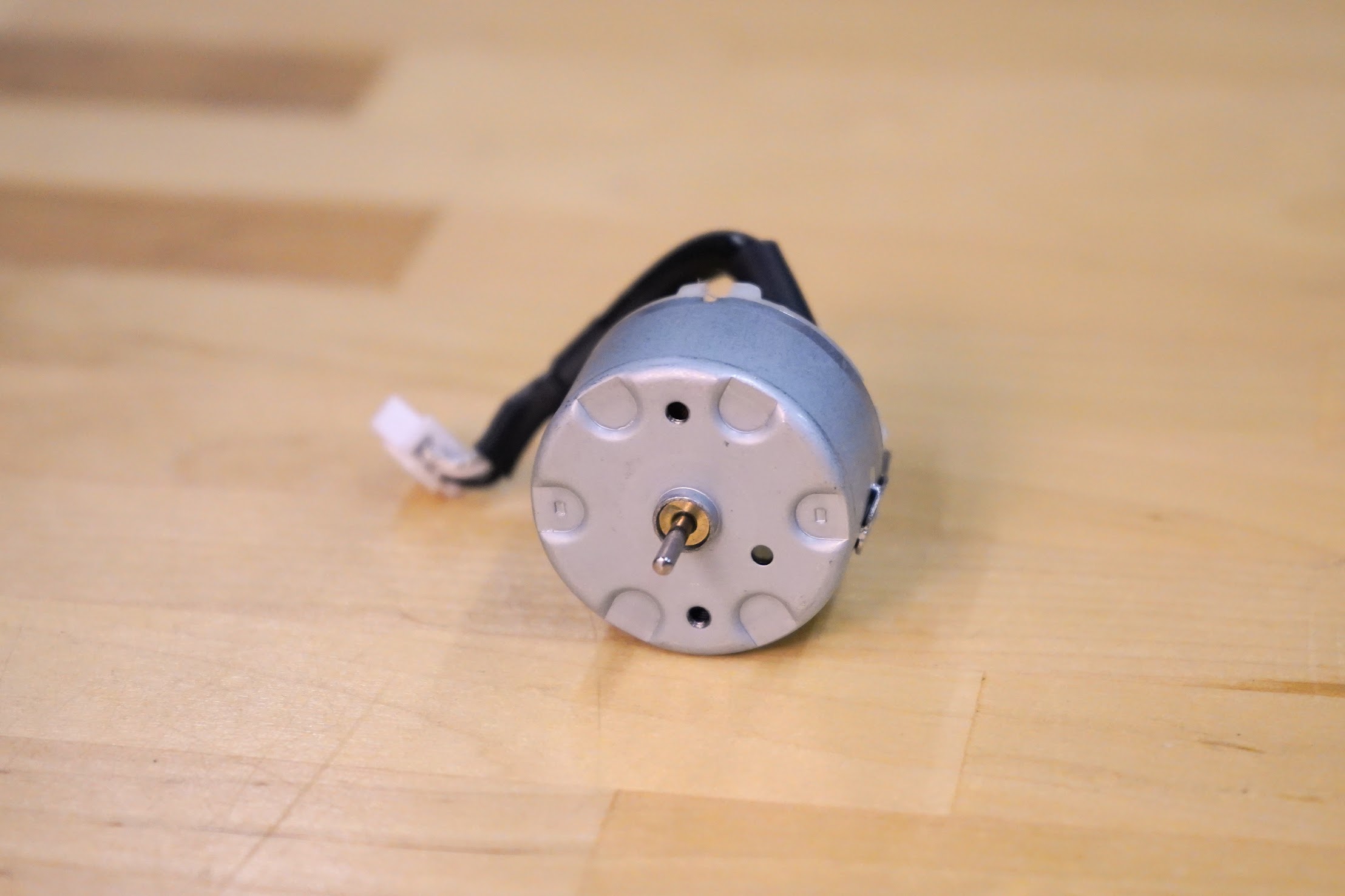

Motor

These powerful 200 resolution stepper motors allow FarmBot to move precisely in the X, Y, and Z directions. Download the motor spec sheet and encoder spec sheet.

Specs

| motor resolution | 200 steps/revolution (1.8 deg/step) |

| winding type | Bipolar |

| voltage | 12V |

| current draw | 1.68A max |

| shaft diameter | 5mm diameter |

| mount hole pattern | 4x M3 holes, standard NEMA 17 pattern |

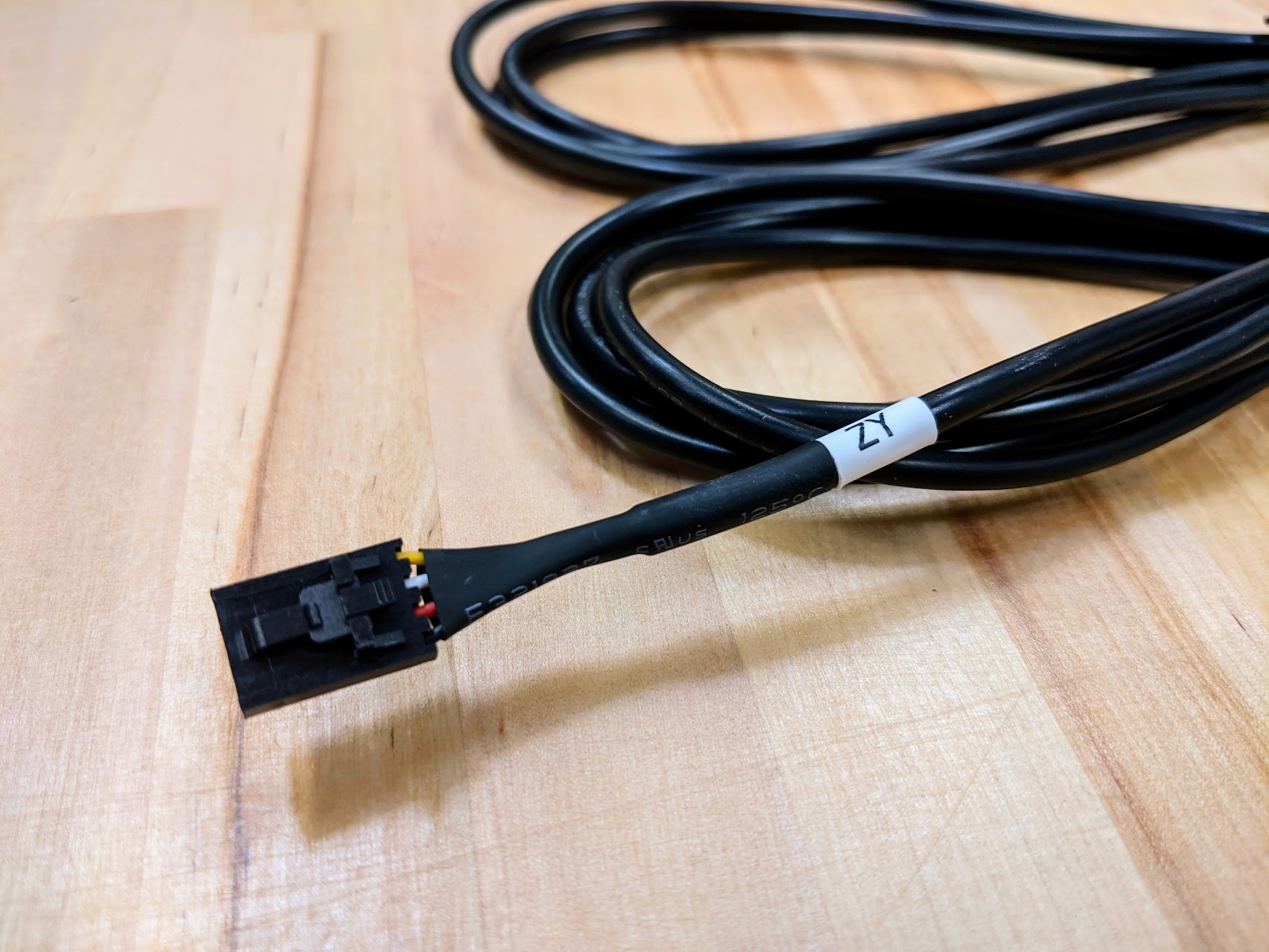

| motor connector | 6-pin connector (only 4 pins used) |

| encoder connector | 8-pin connector |

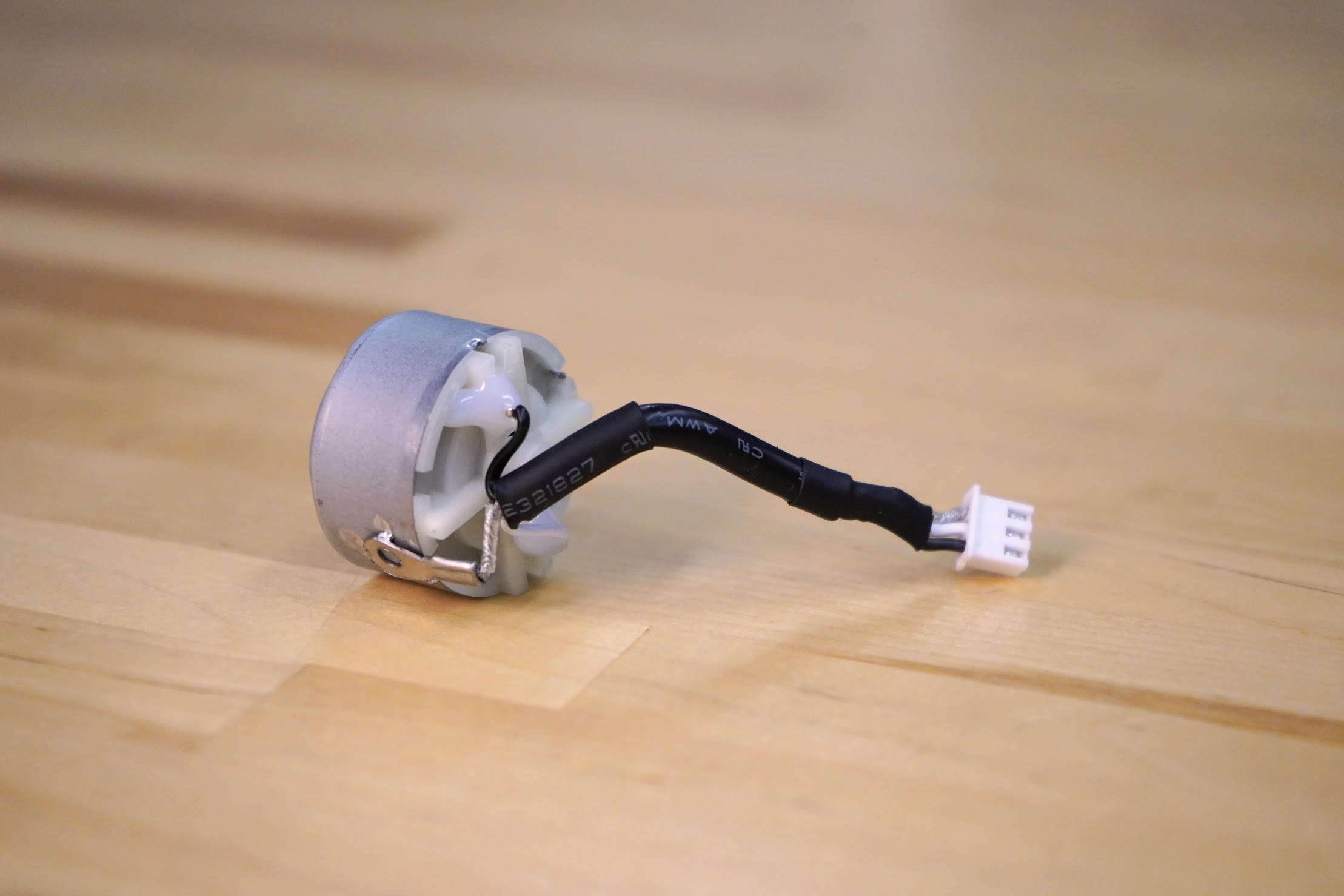

| encoder resolution | 360 lines/revolution |

| encoder output | Differential |

| Price | $70.00 |

| Quantity |

Genesis - 4

Genesis XL - 4 |

| CAD model | Onshape |

| Purchase | The FarmBot Shop |

| internal-part-name | NEMA 17 Stepper Motor w/ Rotary Encoder |

| vendor | Motor - LDO Encoder - Honest Sensor |

| cost | $33.90 |

| notes | Logo engraving must NOT be stretched. Please send photo of first samples to verify. Insert into motor box with FarmBot logo facing DOWN. |

Component tests

| Test | Description | Target | Tolerance |

|---|---|---|---|

| Motor length | Measure the length of the motor body (no encoder or shaft) using digital calipers. | 47.3mm | +/- 0.5mm |

| Motor housing fit | Mount a motor to the cross-slide plate with a horizontal motor housing. Mount a motor to the z-axis motor mount and cover with the vertical motor housing. |

Motor should fit inside housing | N/A |

| Shaft | Mount a GT2 pulley onto the motor shaft according to the FarmBot system design. | Pulley should mount as expected | N/A |

| Shaft length | Measure the length of the motor shaft using digital calipers. | 22mm | +/- 0.5mm |

| Mounting holes | Mount a motor to a cross-slide plate according to the FarmBot system design. | Screws should thread into motor as expected | N/A |

| Motor operation | Connect the motor to a Farmduino and issue a movement command. | Motor should operate as expected | N/A |

| Encoder | Connect the motor and encoder to a Farmduino, issue a movement command, and inspect the encoder position in the web app. | Encoder position values should update as expected | N/A |

| Engraving | Inspect the FarmBot logo engraving. | Must not be stretched | N/A |