Pallet Stacking

Instructions for palletizing Genesis and Genesis XL kits

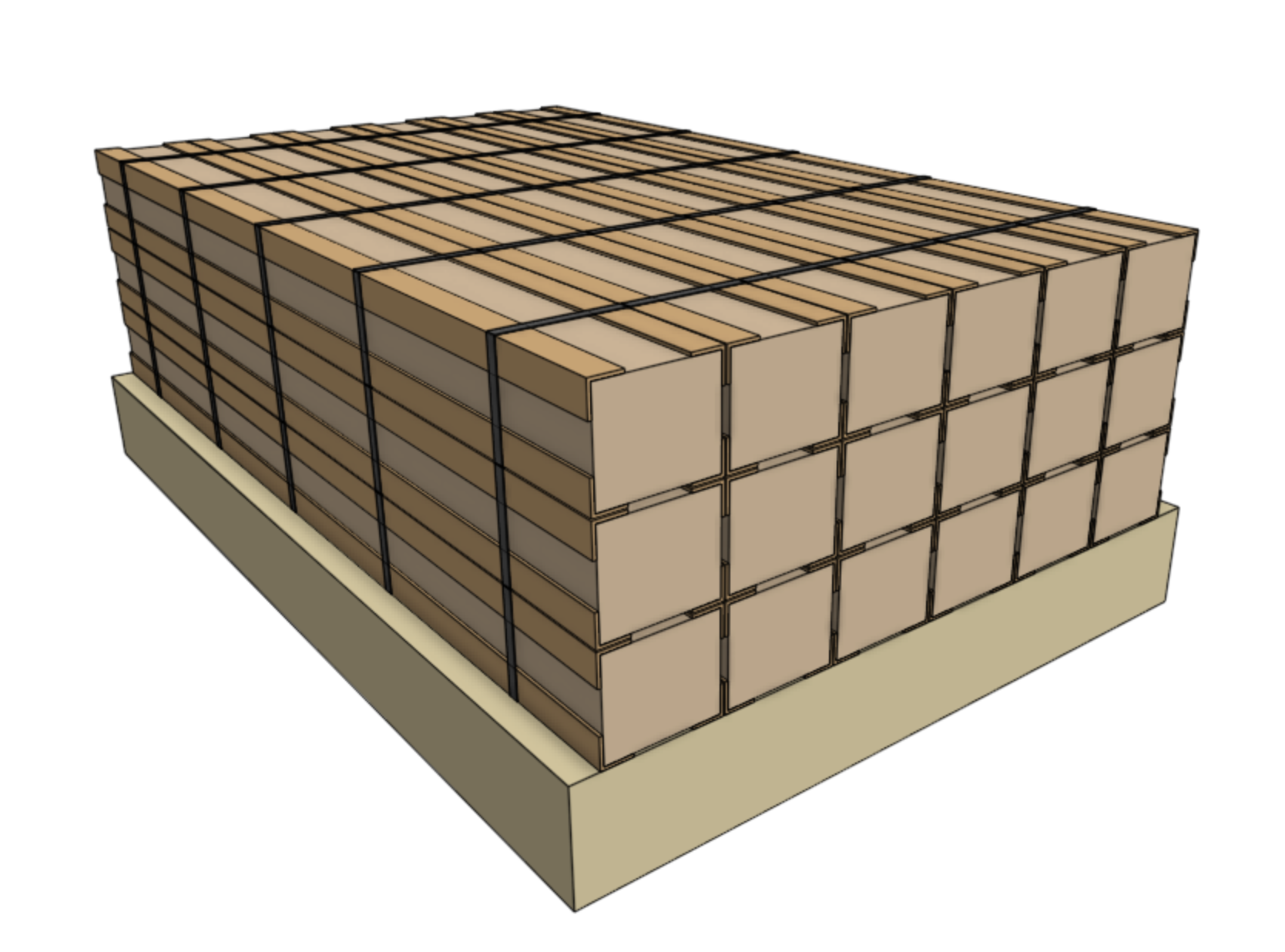

Main cartons

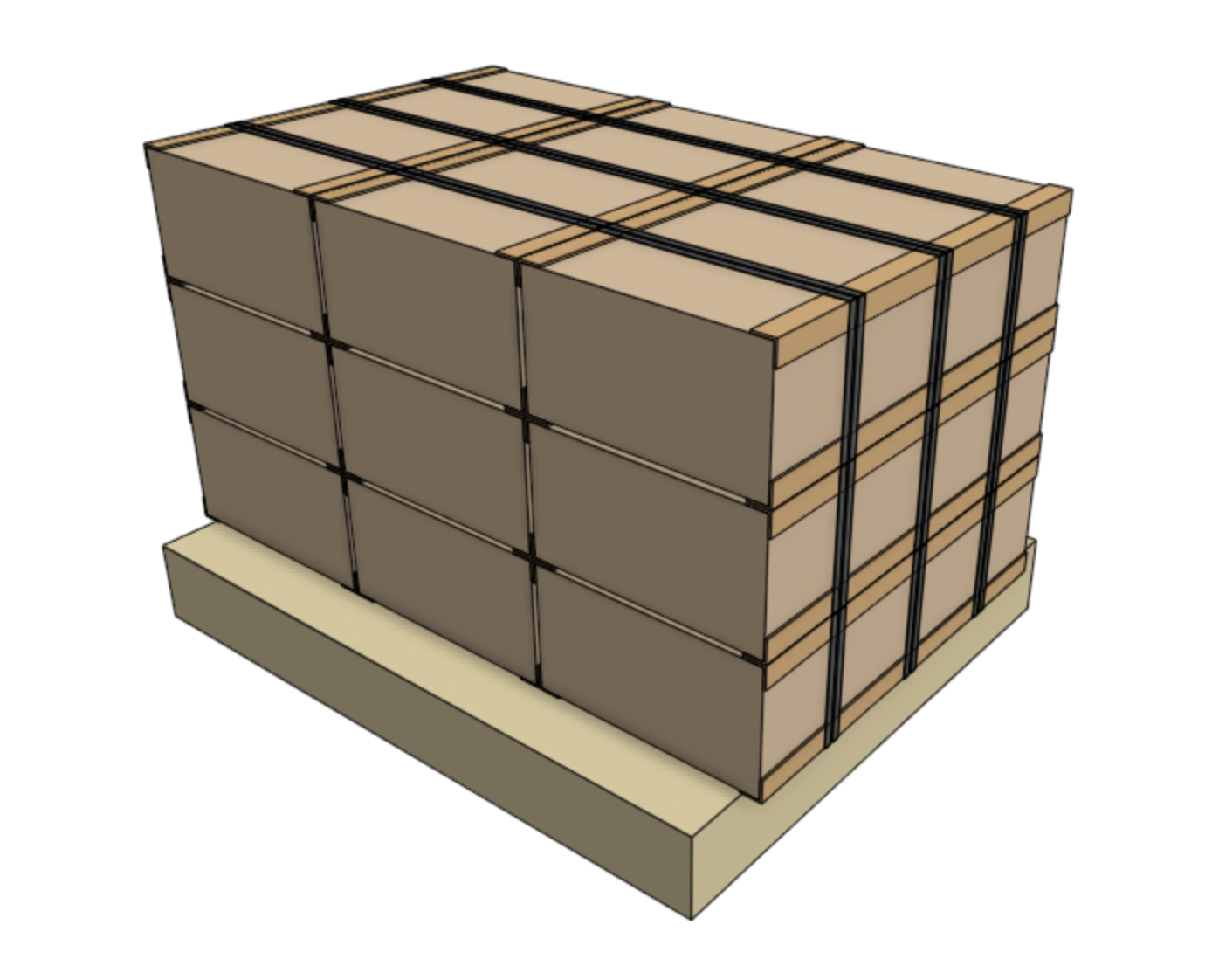

Step 1: First three layers

Stack three layers of main cartons onto a standard sized pallet.

Center the kits

Ensure the kits are centered on the pallet. This will minimize overhang and the instability caused by an unevenly loaded pallet.

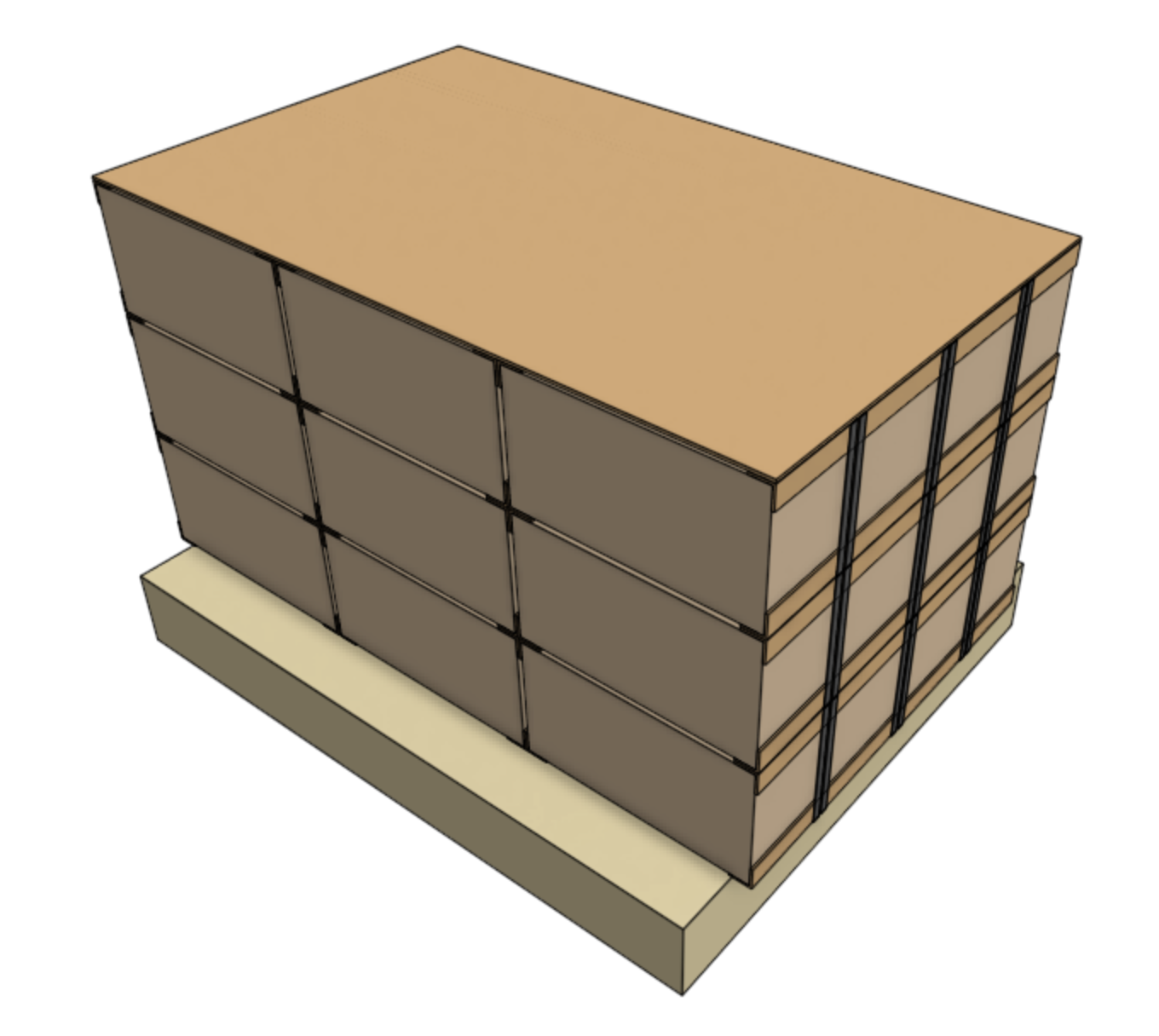

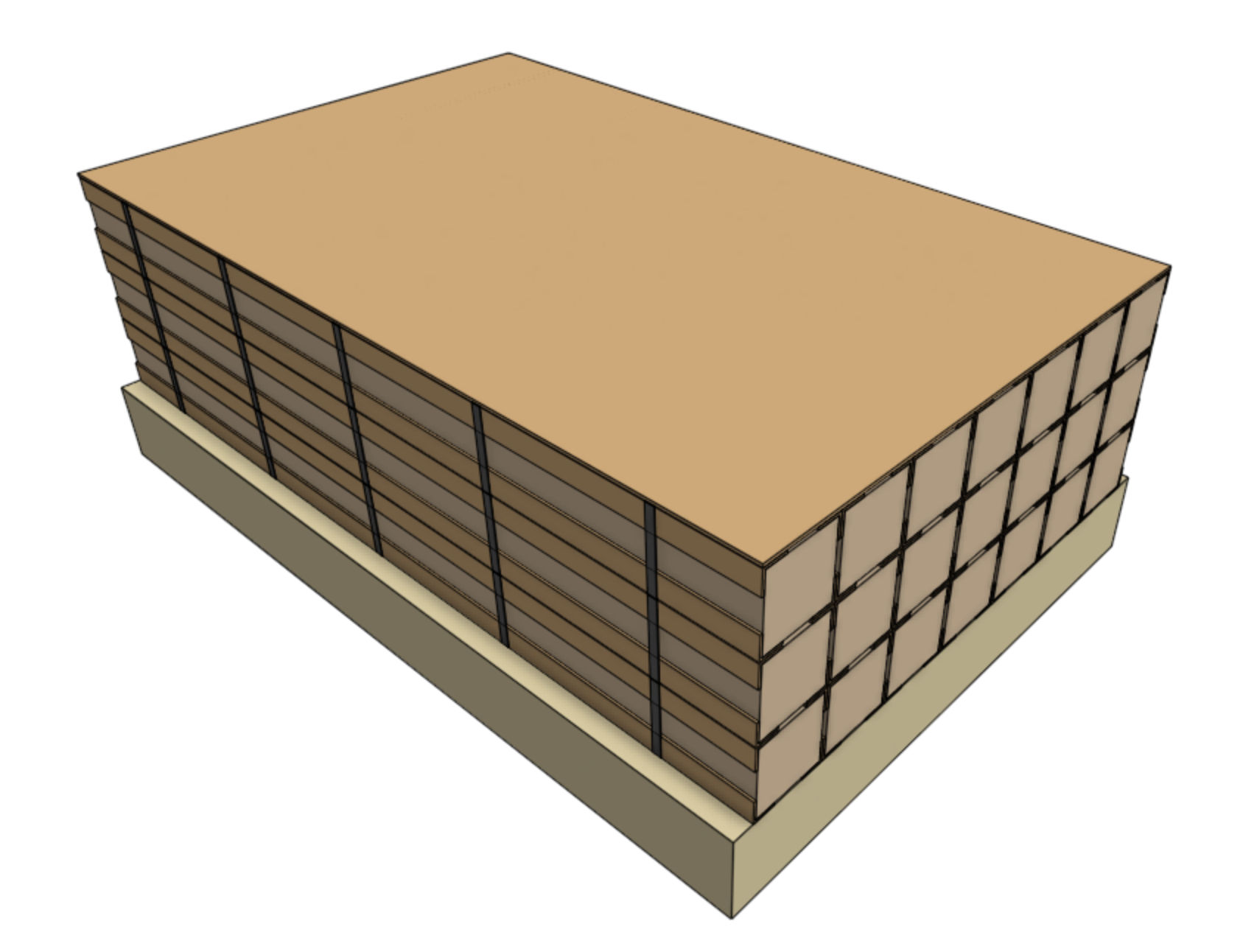

Step 2: Cardboard separator

Place a cardboard separator on top of the first three layers. This will help stabilize the stack.

Step 3: Three more layers

Place three more layers of main cartons onto the stack.

Step 4: Plastic wrap

Wrap the entire stack with clear plastic.

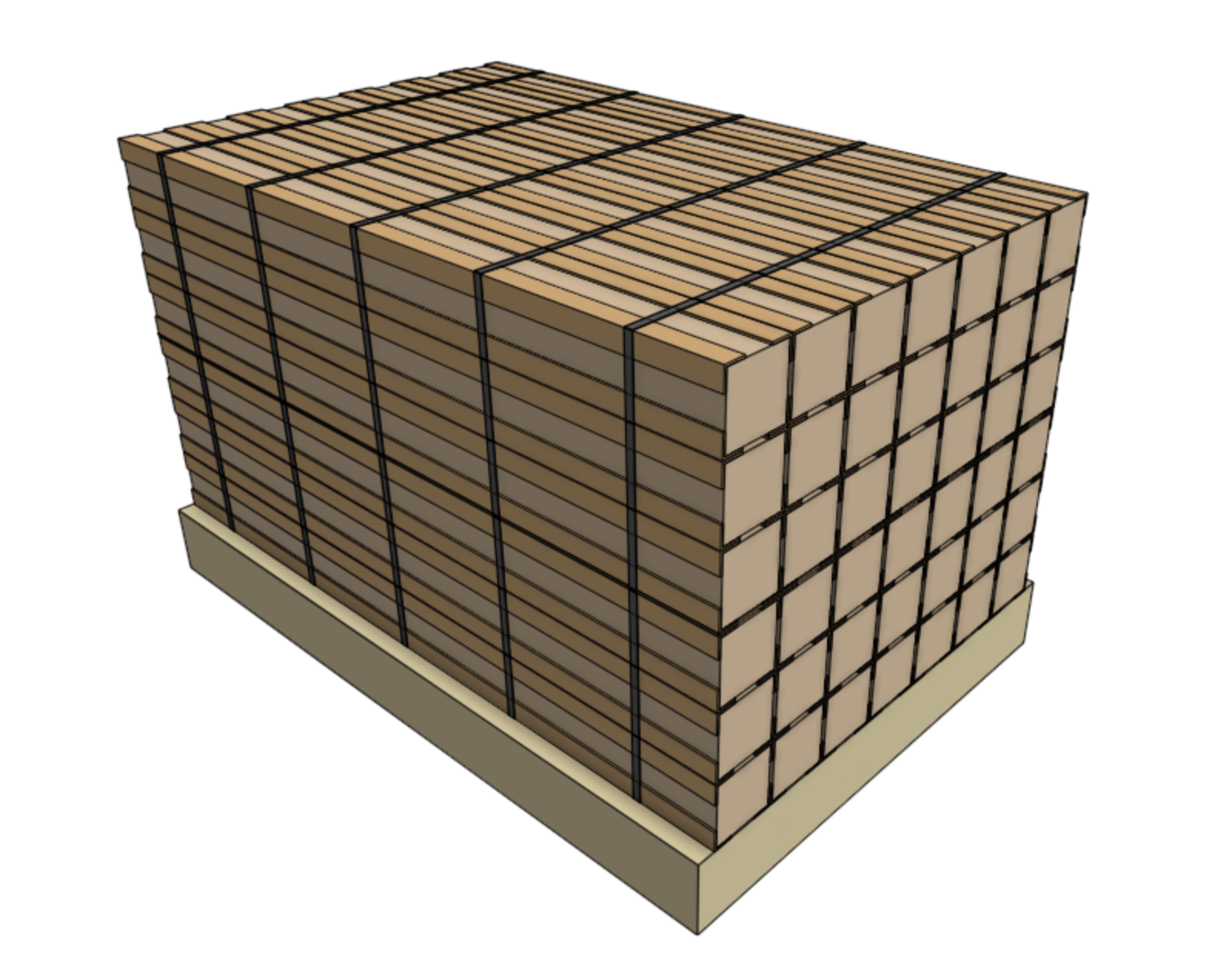

Extrusion and leadscrew kits

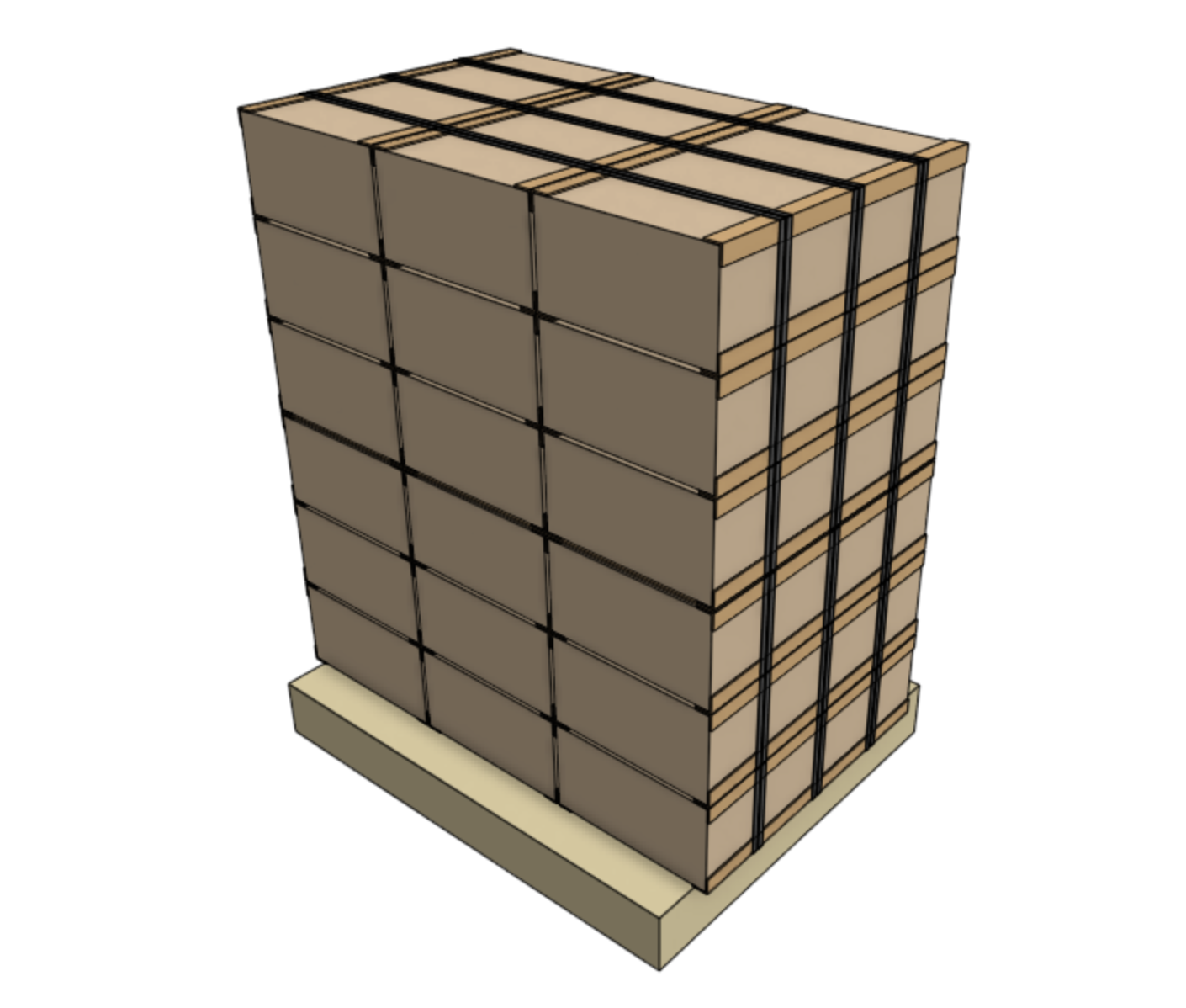

Step 1: First three layers

Stack three layers of extrusion and leadscrew kits onto an extended-length pallet. Genesis kits should have 7 boxes per layer, while Genesis XL should have 6 boxes per layer.

Center the kits

Ensure the kits are centered on the pallet. This will minimize overhang and the instability caused by an unevenly loaded pallet.

Genesis kits (7 on each layer)

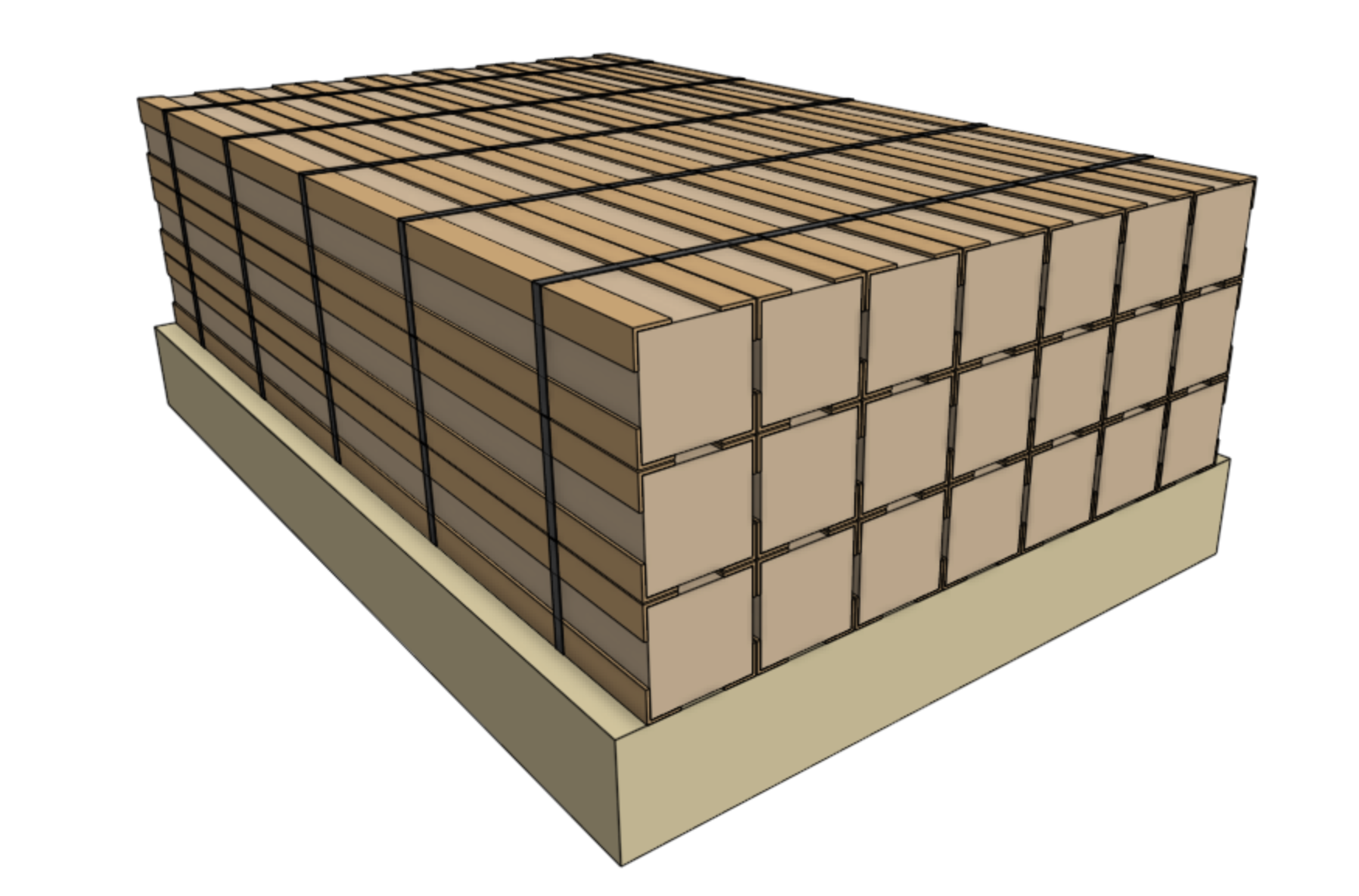

XL kits must be stacked horizontally to provide better stability.

Genesis XL kits (6 on each layer)

Step 2: Cardboard separator

Place a cardboard separator on top of the first three layers. This will help stabilize the stack.

Step 3: Second three layers

Place three more layers of extrusion and leadscrew kits onto the stack.

Step 5: Plastic wrap

Wrap the entire stack with clear plastic.

Reference tables

Stacked pallet specs

| Contents | Qty/pallet | Dimensions (L x W x H) | Product Weight |

|---|---|---|---|

| Genesis main cartons (19kg) | 18 | 1300 x 1020 x 1570mm | 342kg |

| Genesis extrusion and leadscrew kits (10 kg) | 42 | 1530 x 1020 x 970mm | 420kg |

| Genesis XL main cartons (23 kg) | 18 | 1300 x 1020 x 1570mm | 414kg |

| Genesis XL extrusion and leadscrew kits (17 kg) | 36 | 1530 x 1020 x 970mm | 612kg |

Maximizing pallet efficiency

Kits ordered in multiples of the quantities shown below will maximize pallet stacking efficiency (no partially stacked pallets). However, it is more important to maximize the shipping container packing efficiency (see next section) than pallet packing efficiency.

| FarmBot | Kit Quantity | Pallet Quantity | Pallet Length |

|---|---|---|---|

| Genesis | 126 | 7 (main cartons) 3 (extrusion and leadscrew kits) 10 total |

7 x 1.3m 3 x 1.53m 13.69m total |

| Genesis XL | 36 | 2 (main cartons) 1 (extrusion and leadscrew kits) 3 total |

2 x 1.3m 1 x 1.53m 4.13m total |

Maximizing container efficiency

A standard 40’ shipping container has just over 12m of internal length and is wide enough for two rows of standard width pallets. This allows for a maximum of 24m of standard-width pallet length to be loaded. Realistically though, pallets will not be perfectly stacked or perfectly loaded into the container, thus an extra meter or two should be reserved as a safe margin.

Below are just some of the many options for maximizing shipping container packing efficiency (minimal unused floor space inside the container).

| Container Quantity | Contents | Pallet Quantity and Length | Container Efficiency |

|---|---|---|---|

| 1 | 126 Genesis 72 Genesis XL 198 total |

7 x 1.3m = 9.1m 3 x 1.53m = 4.59m 4 x 1.3m = 5.2m 2 x 1.53m = 3.06m 16 pallets, 21.95m |

21.95m/24m = 91% efficient |

| 2 | 168 Genesis 216 Genesis XL 384 total |

10 x 1.3m = 13.0m 4 x 1.53m = 6.12m 12 x 1.3m = 15.6m 6 x 1.53m = 9.18m 32 pallets, 43.9m |

43.9m/48m = 91% efficient |

| 3 | 378 Genesis 252 Genesis XL 630 total |

21 x 1.3m = 27.3m 9 x 1.53m = 13.77m 14 x 1.3m = 18.2m 7 x 1.53m = 10.71m 51 pallets, 69.98m |

69.98m/72m = 97% efficient |