Cross-Slide

Documentation and assembly instructions for the FarmBot Genesis cross-slide

1 hour

This is the estimated time it will take to assemble the cross-slide.

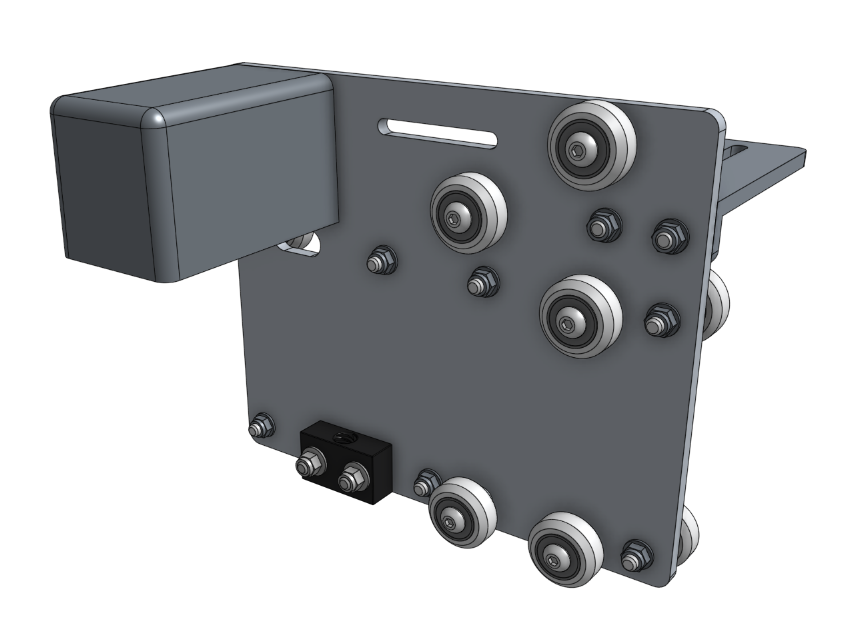

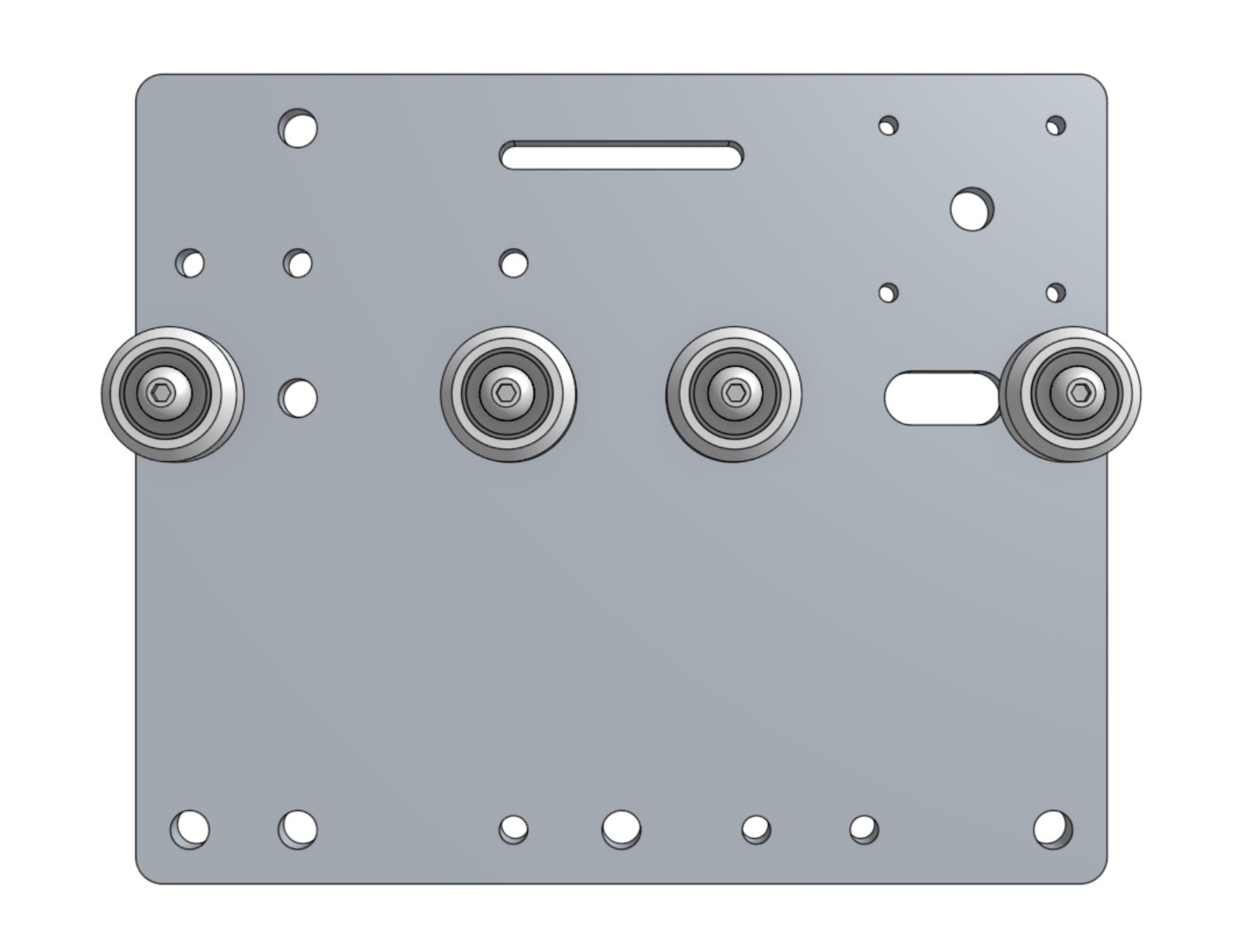

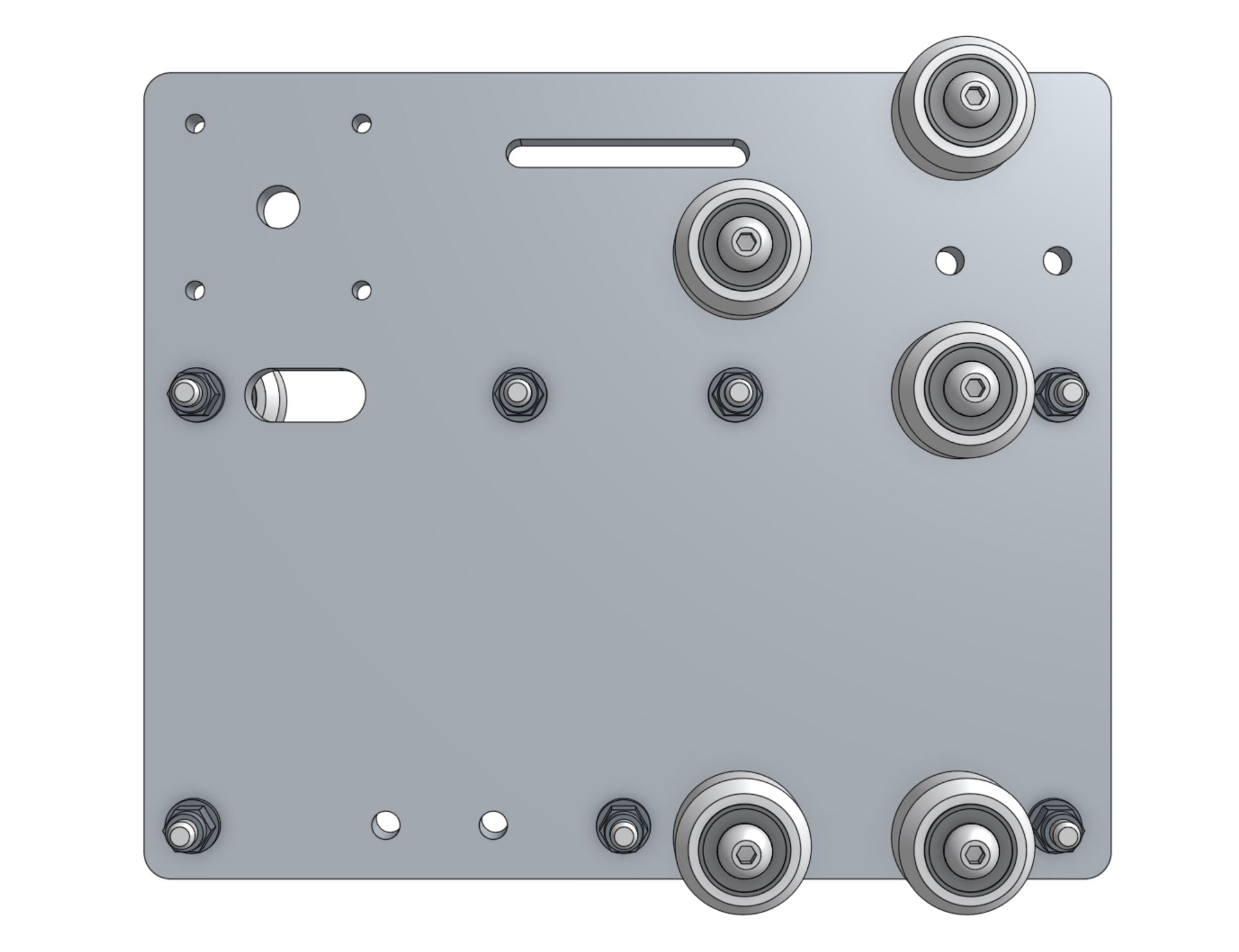

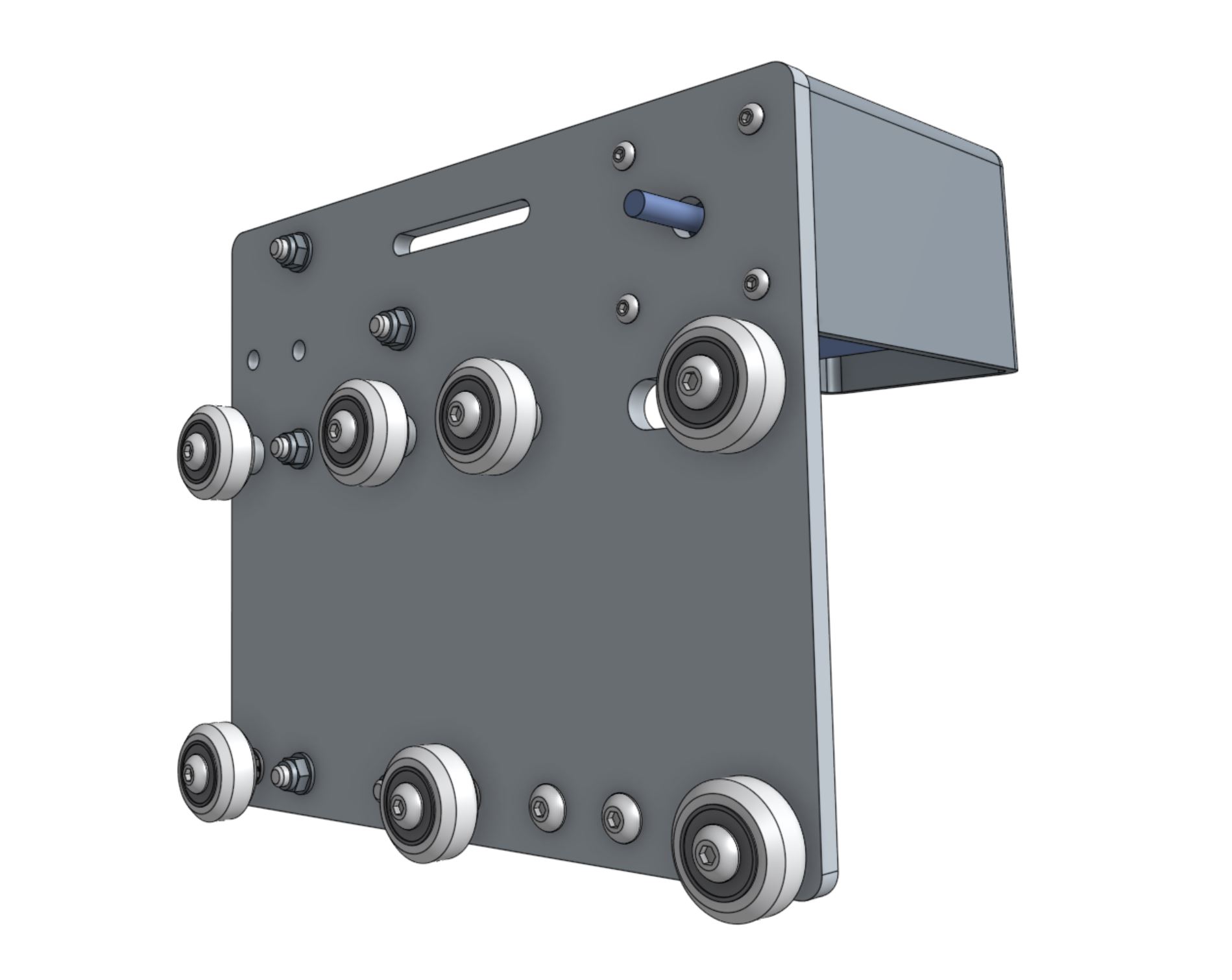

Step 1: Add the gantry V-wheels

Attach four V-wheels with standard spacers to the cross-slide plate using M5 x 30mm screws and M5 flange locknuts.

Make sure you attach the V-wheels to the correct side of the cross-slide plate

Attach three V-wheels with eccentric spacer to the holes shown using M5 x 30mm screws and M5 flange locknuts.

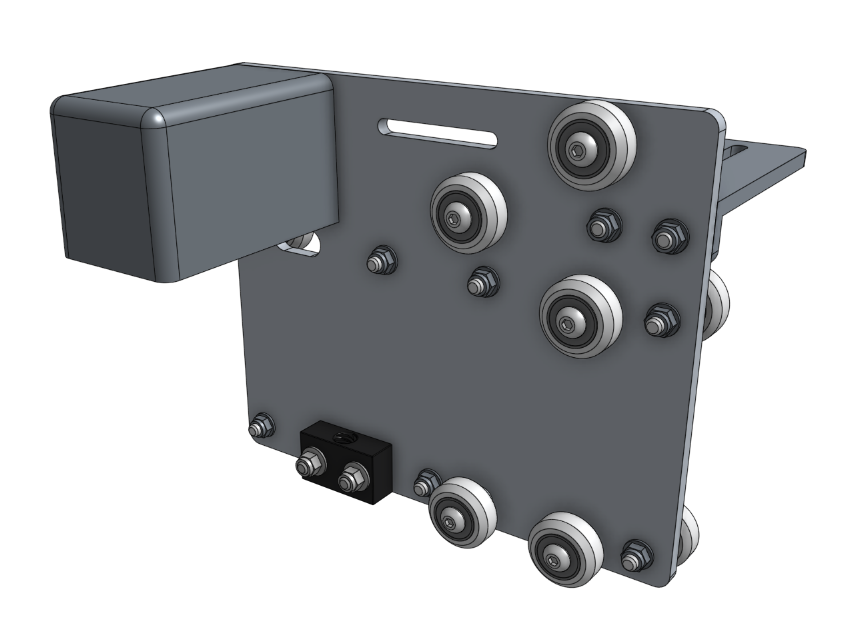

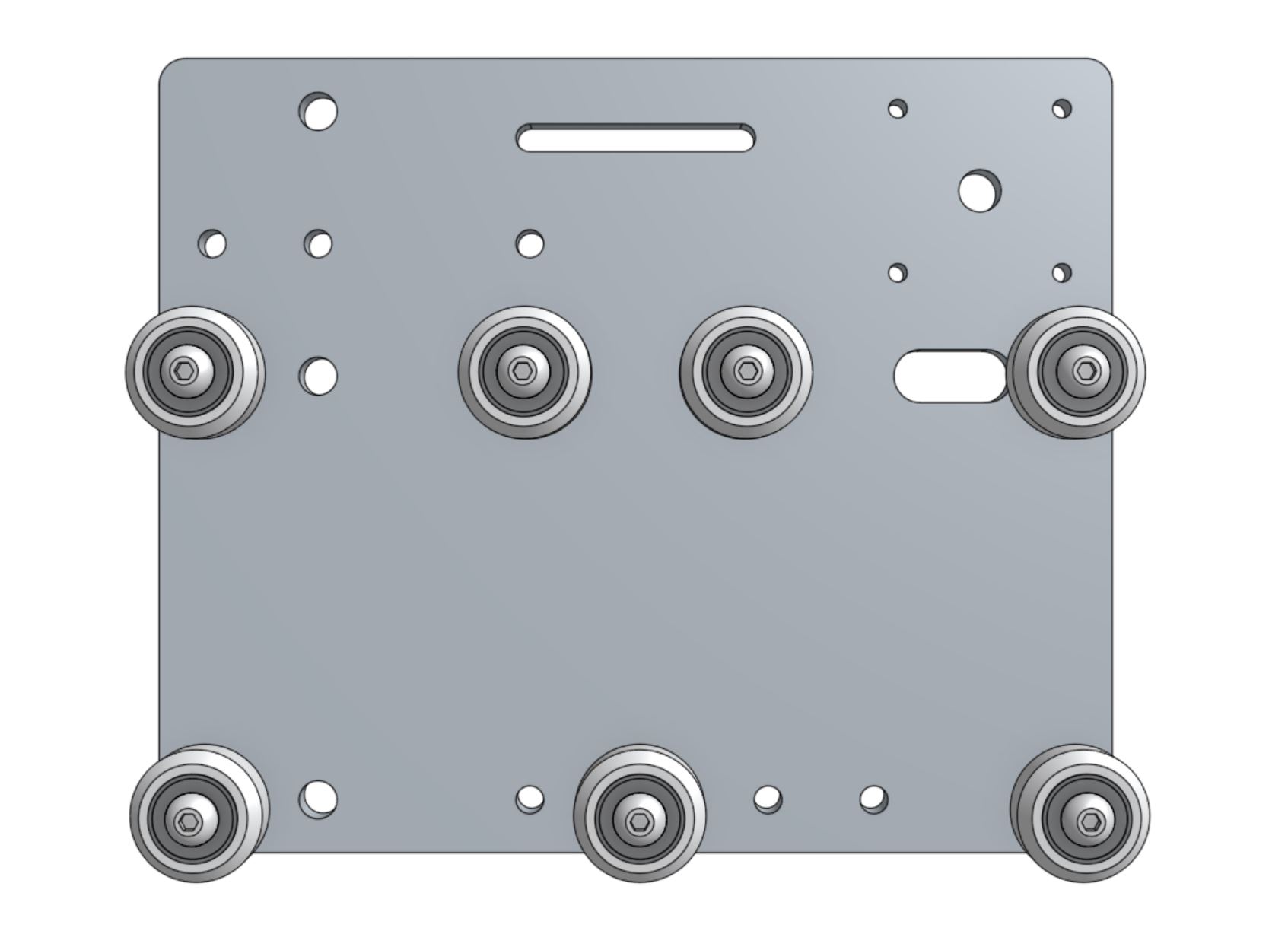

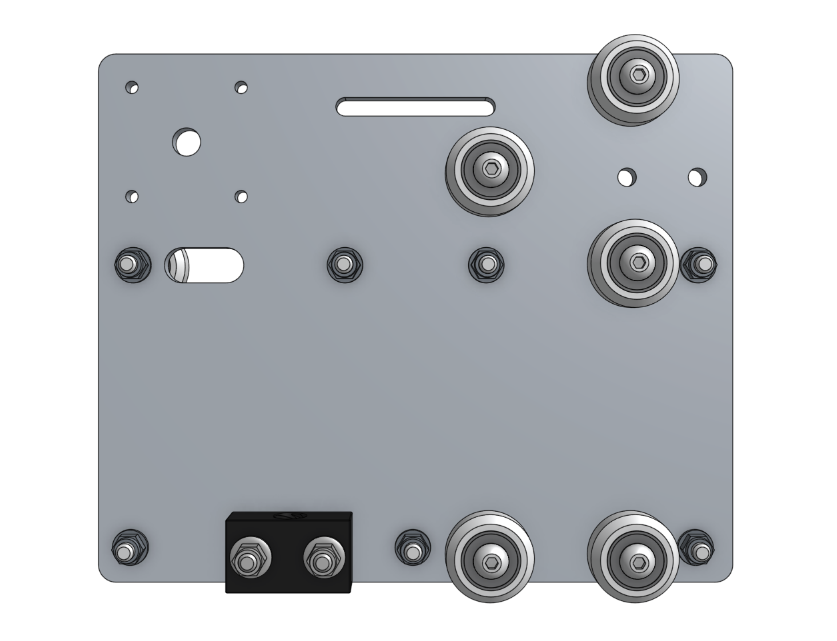

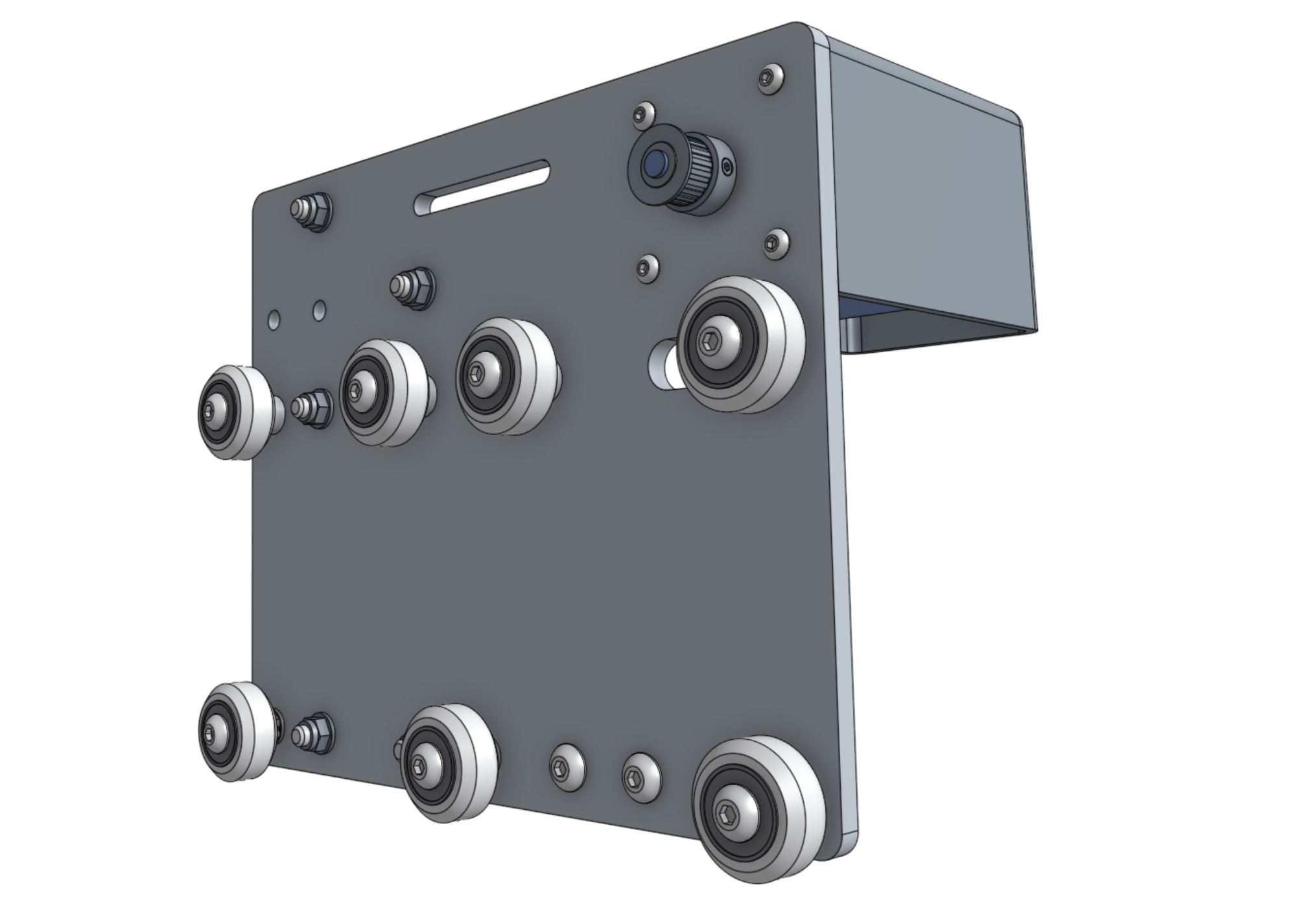

Step 2: Add the Z-axis V-wheels

Flip the cross-slide over so that all of the V-wheels you have added so far are facing away from you.

Attach two V-wheels with standard spacers to the holes shown using M5 x 30mm screws and M5 flange locknuts.

Attach three V-wheels with eccentric spacers to the holes shown using M5 x 30mm screws and M5 flange locknuts.

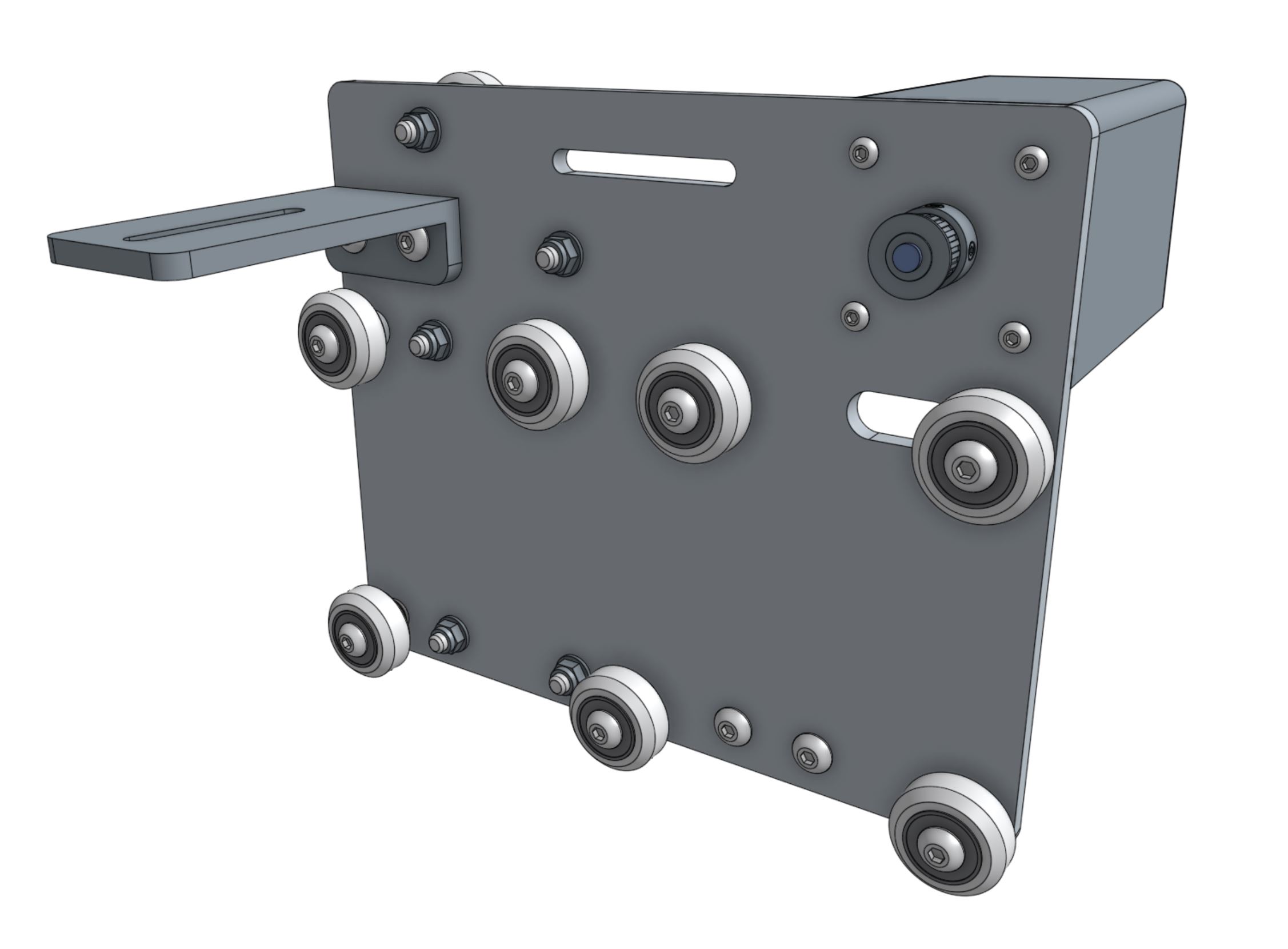

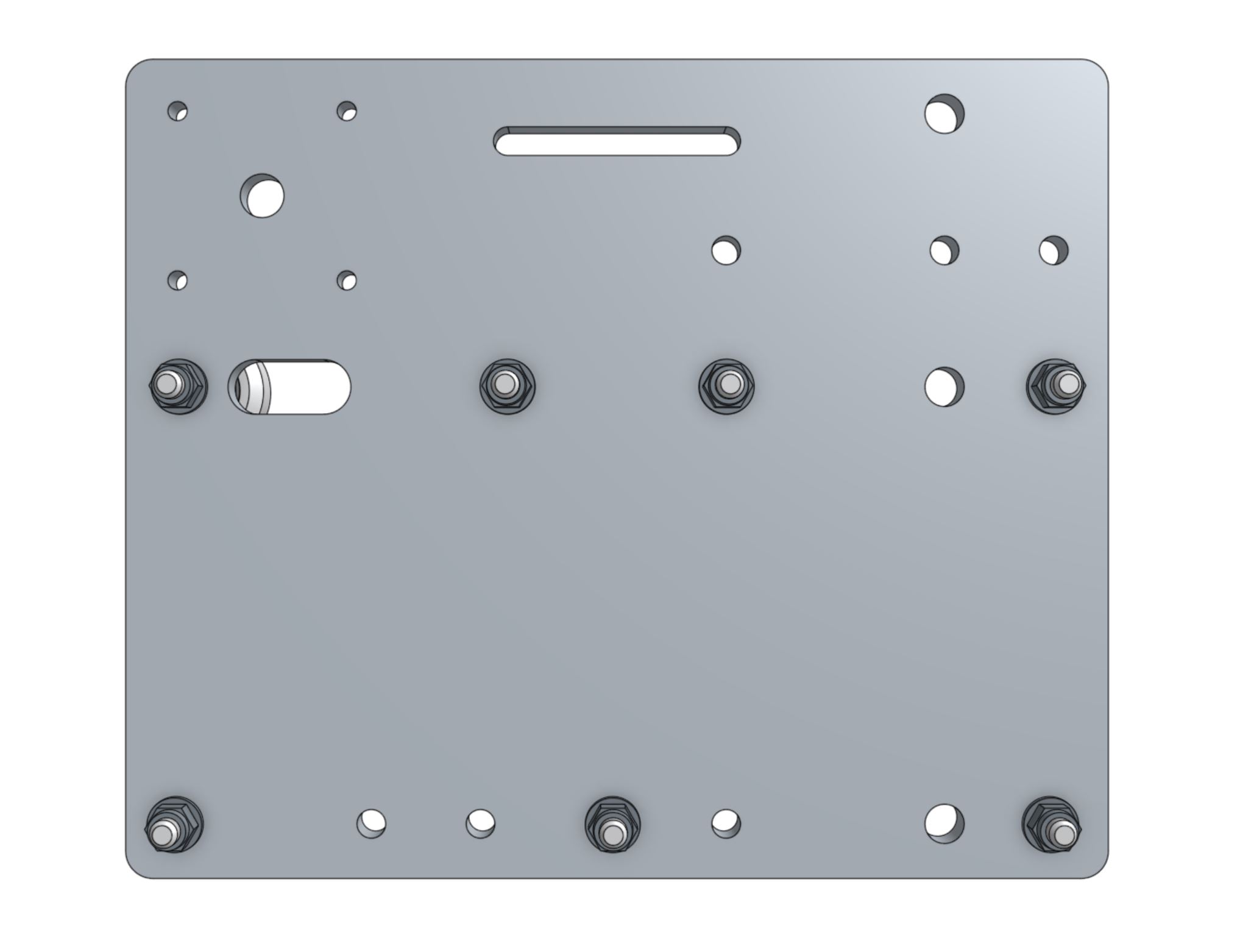

Step 3: Add the leadscrew block

Attach the leadscrew block to the cross-slide plate using M5 x 30mm screws and M5 flange locknuts.

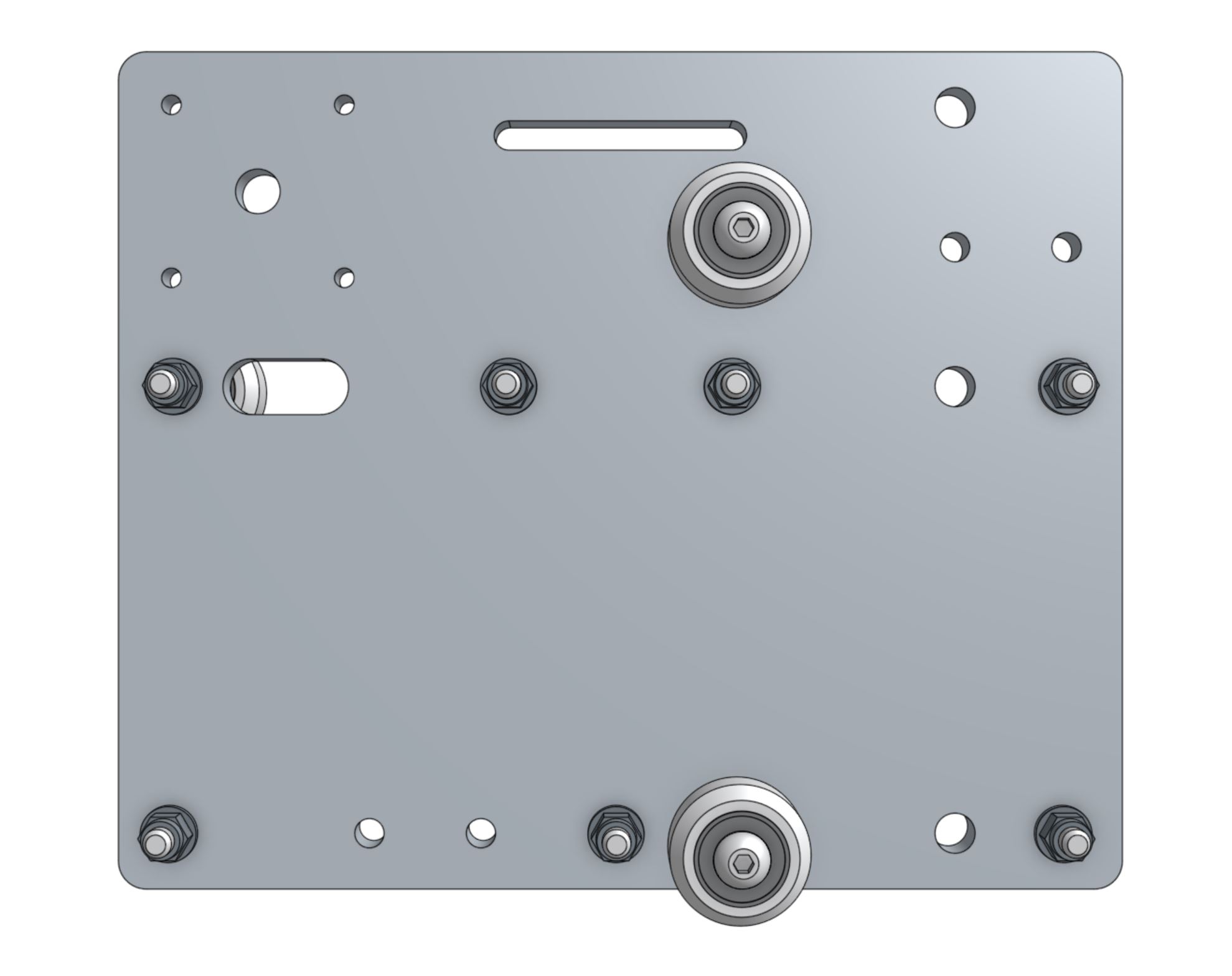

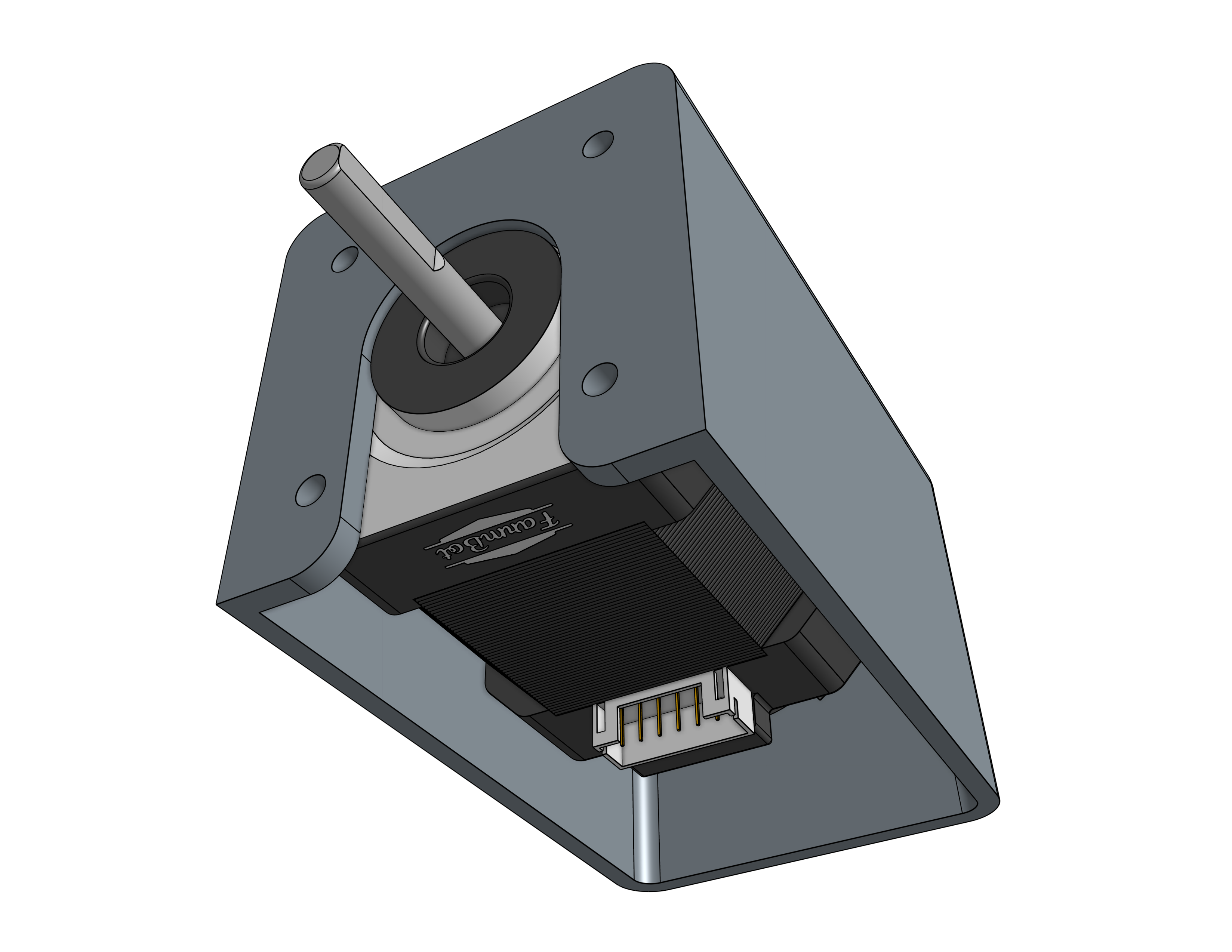

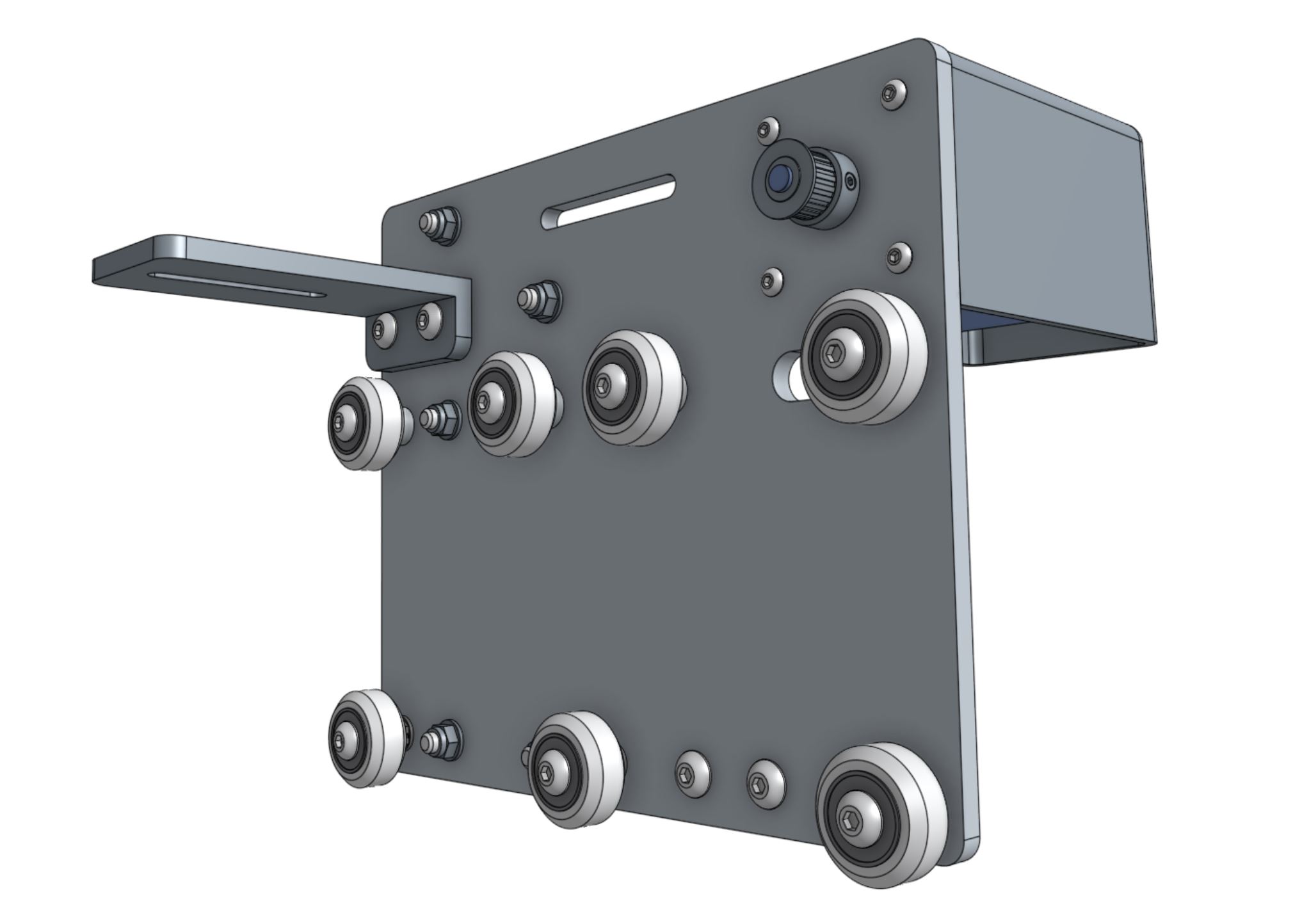

Step 4: Add the stepper motor

Insert a motor into a horizontal motor housing such that the motor and encoder connectors are facing down, out the open face of the housing. Then attach the motor and housing to the cross-slide plate with four M3 x 12mm screws.

Orientation is key

The motor and housing should be on the same side of the cross-slide plate as the delrin leadscrew block and the motor and encoder connectors should be facing down towards the delrin leadscrew block.

Slide a pulley onto the motor shaft. Make sure that both setscrews are lined up with the flat spots of the motor shaft. Then tighten the setscrews with the 2mm hex driver.

Mind the gap

There should be a small gap (about 1mm) between the pulley and the plate to allow the motor to spin freely.

Step 5: Add the cable carrier mount

Attach the 80mm cable carrier mount to the cross-slide plate using M5 x 16mm screws and M5 flange locknuts. The bracket should be on the opposite side of the plate as the motor.

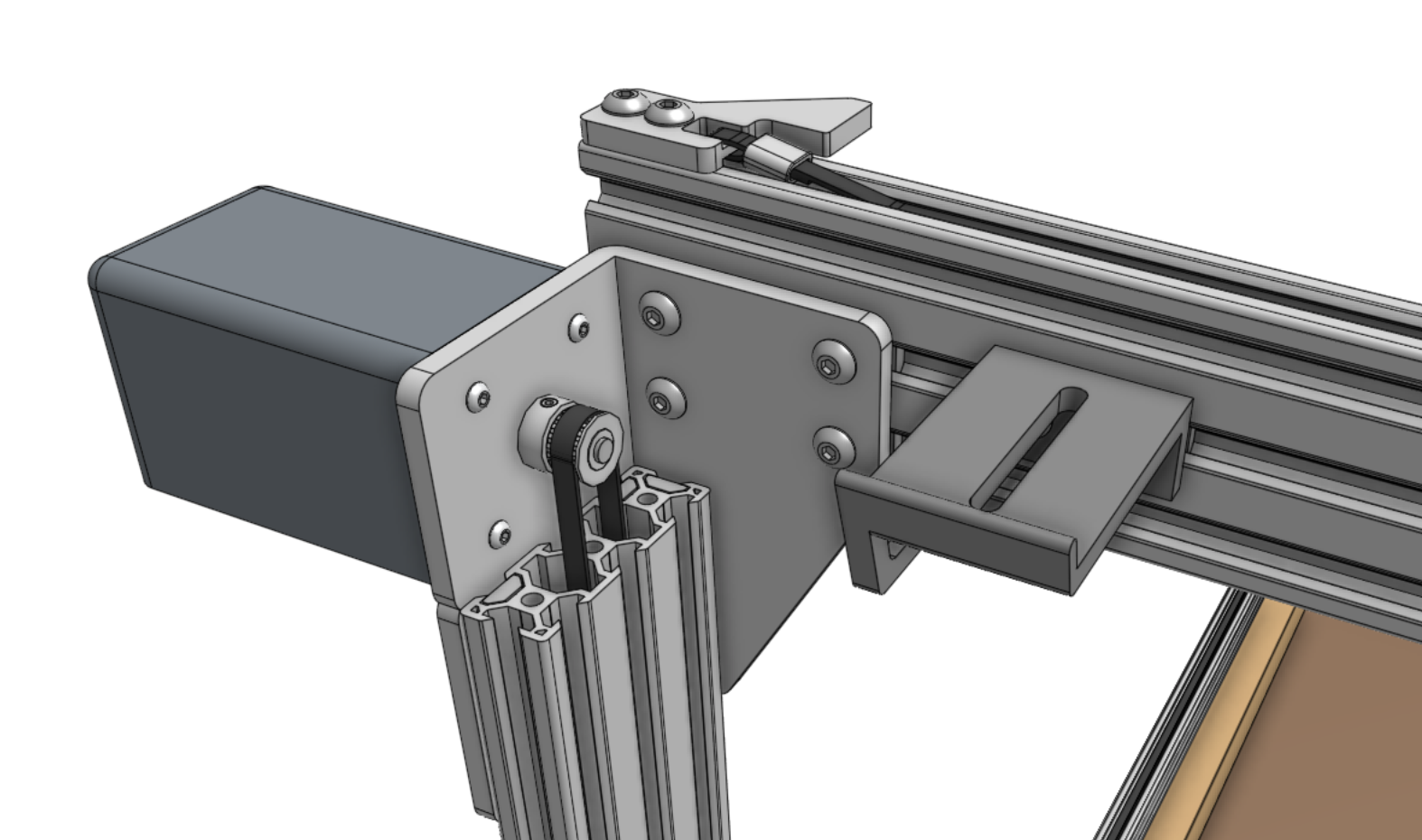

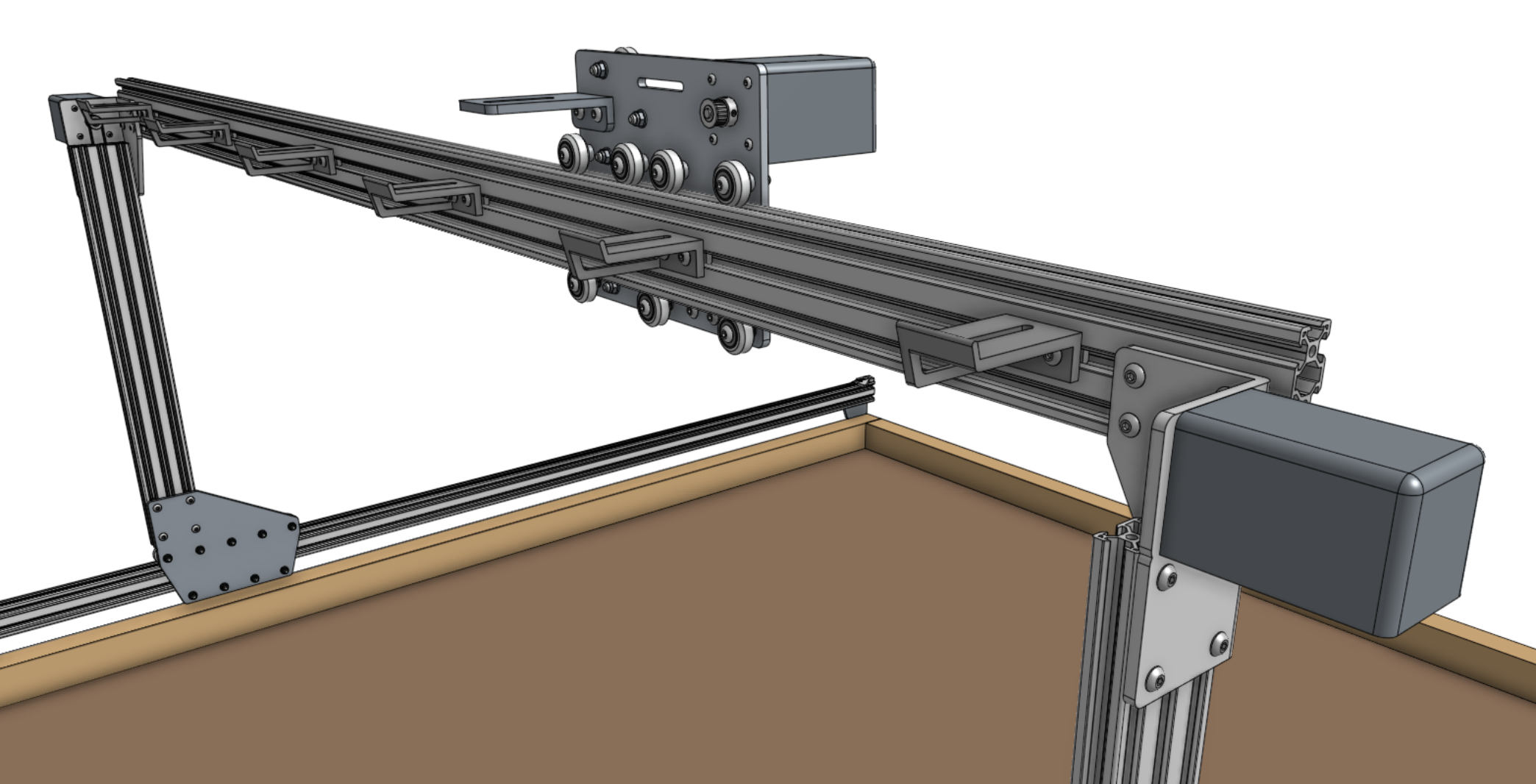

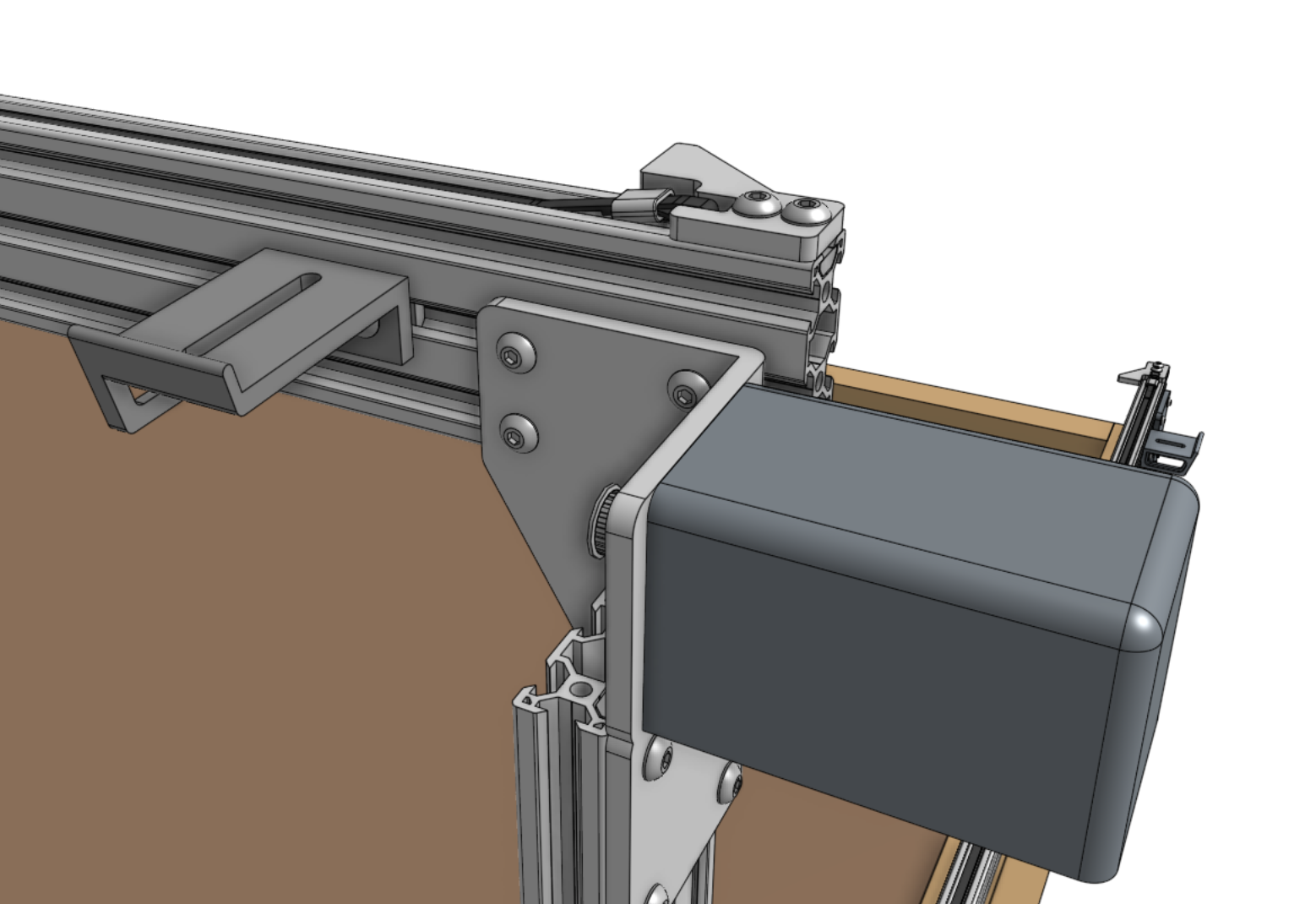

Step 6: Slide the cross-slide onto the gantry main beam

In order for the cross-slide to slide smoothly and wobble-free on the gantry main beam, you must first adjust the eccentric spacers of the bottom three V-wheels. Adjust the eccentric spacers using the eccentric spacer adjustment reference guide.

Once you have adjusted the eccentric spacers, slide the cross-slide onto the gantry main beam.

The cross-slide should move easily across the full width of the gantry. If you feel any significant resistance, re-adjust the eccentric spacers so that there is less resistance to movement. On Genesis XL models, pay special attention at the connection point between the two gantry main beams. If there is any significant bump or resistance to movement at the joint, you may use sand paper to sand away the bump.

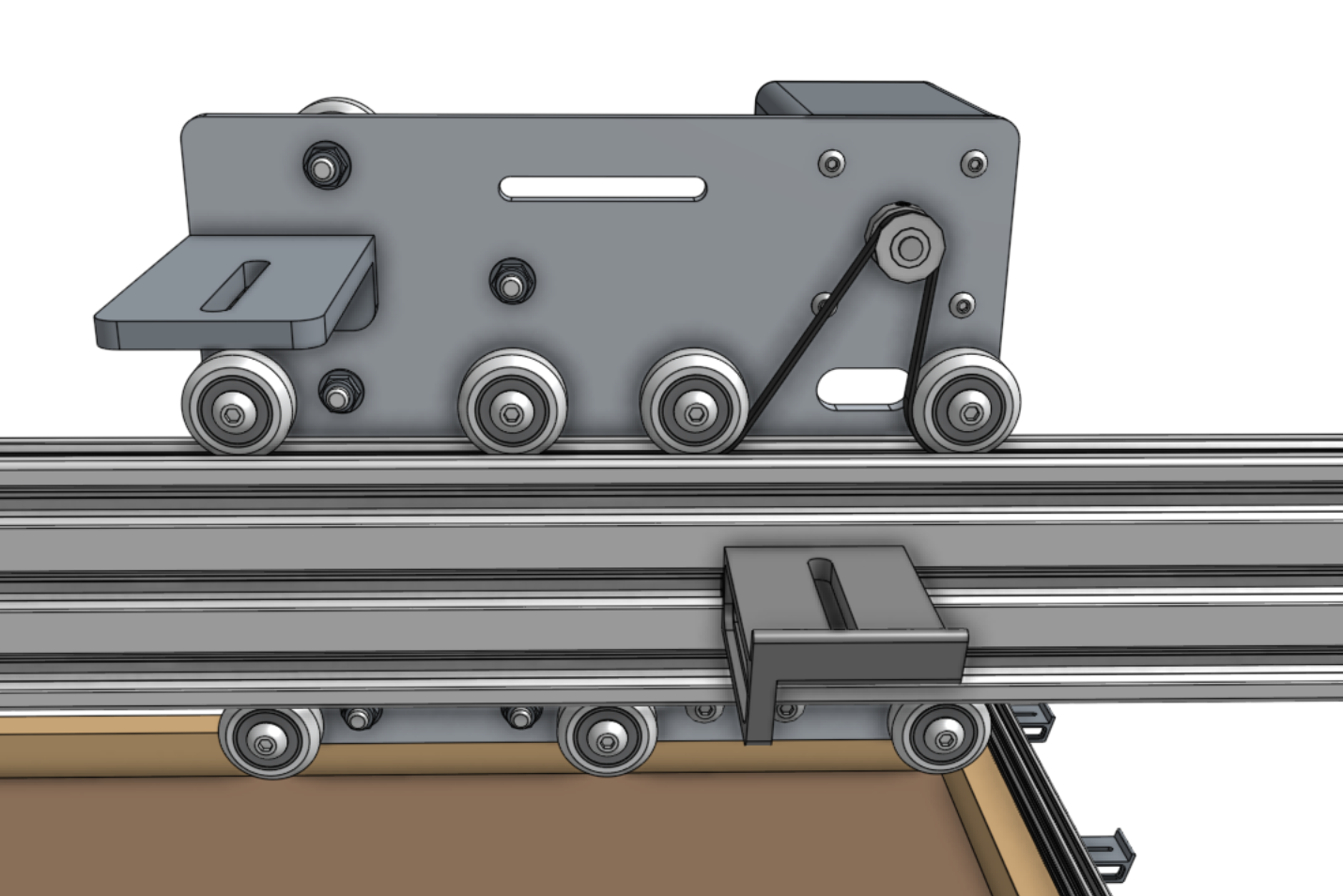

Step 7: Feed and secure the belt

Attach a belt clip to the end of the gantry main beam using two M5 x 10mm screws and a 20mm nut bar. Then secure one end of the y-axis GT2 timing belt (2m long for Genesis, 3.5m long for XL) to the belt clip using the belt installation reference guide.

Feed the belt under the end V-wheel of the cross-slide, then over the pulley and under the remaining three V-wheels. The flat side of the belt should be in contact with your V-wheels while the toothed side should engage with the teeth on the pulley.

Make sure that the belt is not twisted anywhere.

Secure the belt at the other end of the gantry with another belt clip, 20mm nut bar, and two M5 x 10mm screws. Ensure there is a small amount of tension on the belt once everything is in place.